Integral groove base directly-buried self-standing non-metal sound barrier and mounting method thereof

An installation method and sound barrier technology, applied in the direction of noise absorption devices, buildings, etc., can solve the problems of reducing the installation difficulty of sound insulation, supporting system cost, self-weight, poor durability, etc., to reduce self-weight and transportation costs, stress Increased performance and solved the effect of difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

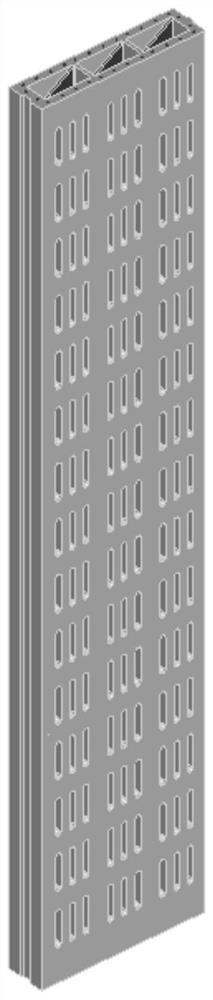

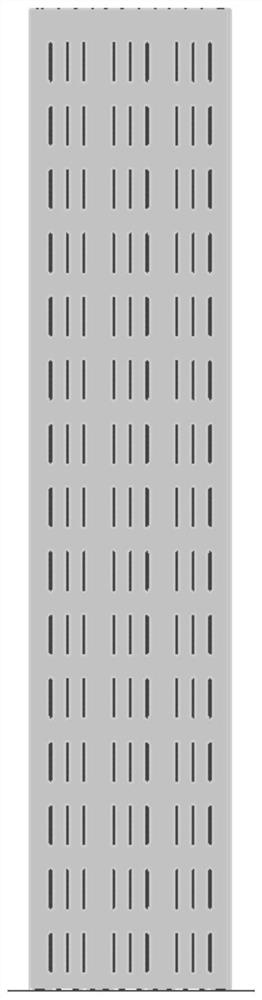

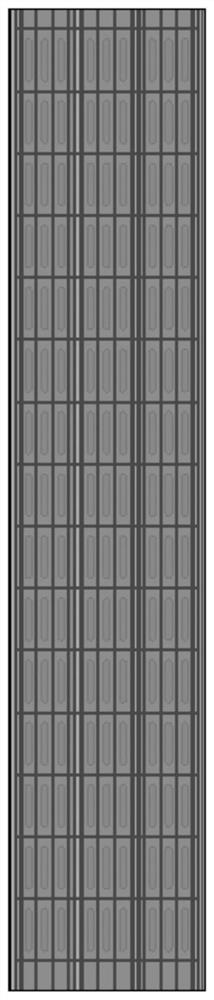

[0044] This example provides an integral groove base direct-buried self-supporting non-metallic sound barrier, including the main body of the sound barrier. The main body of the sound barrier is a direct-buried self-supporting structure. Four ribs, the panel, the back plate and the four ribs form a middle cavity, and the middle cavity is not filled with sound-absorbing materials. like Image 6 As shown, the large-cavity sound barrier is not filled with sound-absorbing boards, the height is 3m, the backboard and front panel reinforcement is 200mm×200mm medium-strength prestressed steel wire mesh with a nominal diameter of 5mm, and the backplane and panel thickness is 30mm; the lower end is made of The pre-buried type is fixed by grouting, and the vertical joints of the sound barrier are sealed with water-stop strips. The surface opening rate is 20%, and it is installed on both sides of the road to absorb noise;

[0045]Among them, the ultra-high-performance cement-based fiber ...

Embodiment 2

[0050] This example provides a self-supporting non-metallic sound barrier directly buried with an integral groove base, such as Figure 1-5 As shown, in this example, in addition to filling the sand-based particle sound-absorbing panel (wherein, the sand is quartz sand, and the particle size of the sand is 0.5-1.0mm; the bending bearing capacity of the sand-based sound-absorbing panel is ≥7kPa, the impact resistance is ≥35J, Connecting material is 72.5R grade Portland cement), other conditions are all identical with embodiment 1.

Embodiment 3

[0052] In this example, except that the foamed metal sound-absorbing board is filled (wherein, the material of the foamed metal sound-absorbing board is a foamed aluminum material), other conditions are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com