Carbon fiber self-stress concrete pressure pipeline material

A technology of pressure pipes and carbon fibers, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc. It can solve problems such as poor corrosion resistance, high welding process requirements, and external leakage of water supply pipes, so as to achieve enhanced mechanical properties and durability, and good chemical resistance. Corrosion properties, effects of reducing temperature shrinkage and drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

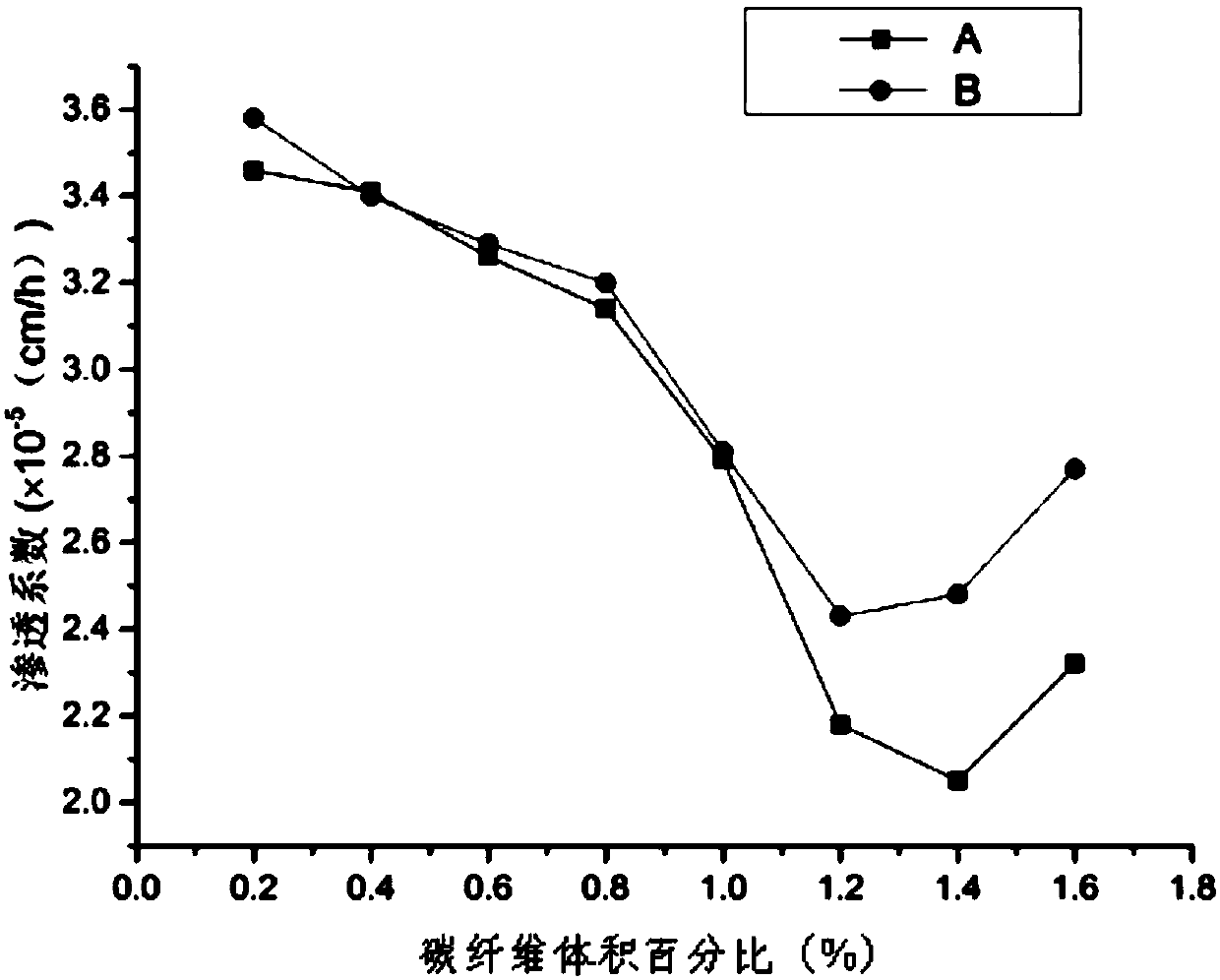

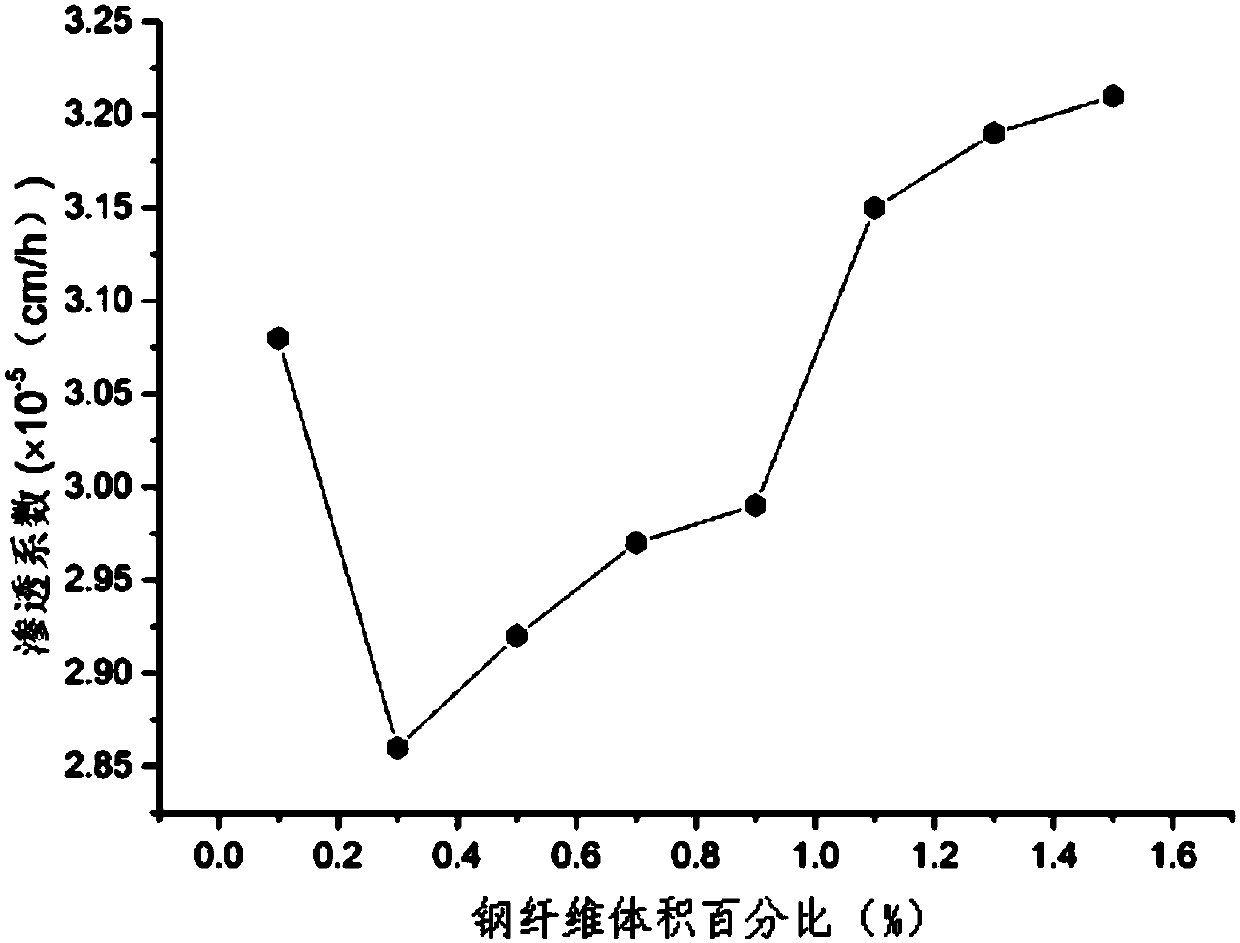

Embodiment 1

[0024] A carbon fiber self-stressing concrete pressure pipe material, the carbon fiber self-stressing concrete pressure pipe material per cubic meter includes the following raw materials: C30 cement concrete 2178kg, polyacrylonitrile-based carbon fiber 26kg and UEA expansion agent 191kg, wherein, C30 cement concrete contains cement 381kg, water 169kg, sand 615kg and stone 1013kg, the cement is ordinary Portland cement P.O 42.5, the sand is medium sand with a fineness modulus of 2.51, and the maximum particle size of the stone is not greater than 25mm; the length of the polyacrylonitrile-based carbon fiber is The mass ratio of 4mm polyacrylonitrile-based carbon fiber to 9mm-length polyacrylonitrile-based carbon fiber is 7:4.

[0025] The preparation method of the polyacrylonitrile-based carbon fiber in the above-mentioned carbon fiber self-stressing concrete pressure pipe material is as follows:

[0026] Step 1, extract propane from crude oil, and oxidize to obtain acrylonitril...

Embodiment 2

[0034] A carbon fiber self-stressing concrete pressure pipe material, including the following raw materials: C30 cement concrete 2178kg, polyacrylonitrile-based carbon fiber and UEA expansion agent 174kg, wherein, C30 cement concrete contains 381kg of cement, 169kg of water, 615kg of sand and 1013kg of stone; The mass percentage of acrylonitrile-based carbon fiber in C30 cement concrete is 0.17%, that is, the volume percentage of polyacrylonitrile-based carbon fiber in carbon fiber self-stressing concrete pressure pipe material is 0.2%; the length of polyacrylonitrile-based carbon fiber in polyacrylonitrile-based carbon fiber is 4mm The mass ratio of polyacrylonitrile-based carbon fiber with a length of 9mm is 7:4.

Embodiment 3

[0036] A carbon fiber self-stressing concrete pressure pipe material, including the following raw materials: C30 cement concrete 2178kg, polyacrylonitrile-based carbon fiber and UEA expansion agent 174kg, wherein, C30 cement concrete contains 381kg of cement, 169kg of water, 615kg of sand and 1013kg of stone; The mass percentage of acrylonitrile-based carbon fiber in C30 cement concrete is 0.34%, that is, the volume percentage of polyacrylonitrile-based carbon fiber in carbon fiber self-stressing concrete pressure pipe material is 0.4%; the length of polyacrylonitrile-based carbon fiber is 4mm The mass ratio of polyacrylonitrile-based carbon fiber with a length of 9mm is 7:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com