Multi-scale polypropylene fiber pumping concrete

A polypropylene fiber, pumping concrete technology, applied in the field of concrete building materials, can solve the problems of loss of suspension state, insufficient mechanical properties, poor crack resistance, etc., to improve mechanical properties and durability, good pumping performance, improve resistance cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Materials used:

[0026] The cement is P·O 42.5R from Chongqing Conch Cement Co., Ltd.;

[0027] The fine aggregate is machine-made sand produced by Chongqing Jinjing Building Materials Co., Ltd., with a fineness modulus of 2.6-3.0;

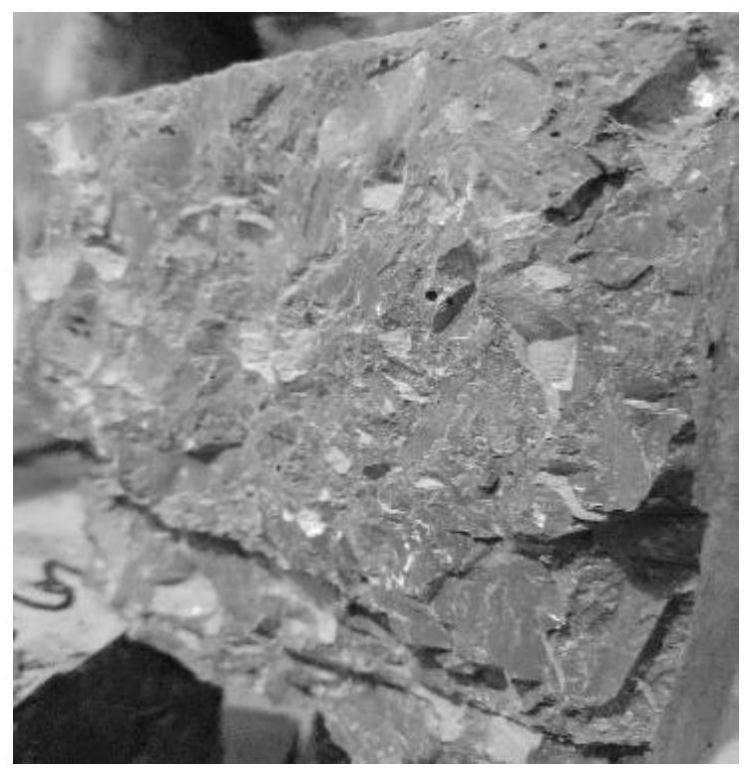

[0028] Coarse aggregate is crushed stone with a particle size of 5-25mm produced by Chongqing Jinjing Building Materials Co., Ltd., which is continuously graded; the particle size of the first coarse aggregate is 5-10mm, and the second particle size of the coarse aggregate is 10-25mm;

[0029] The water reducer is a polycarboxylate high-efficiency water reducer;

[0030] The preservative is Jiangsu Subote SBT-RMA (Ⅱ) high-efficiency concrete preservative.

[0031] Step 1: Determination of the proportion of basic materials (adaptation of slump and expansion).

[0032] Test 1: It consists of the following components by weight: 250 parts of cement, 180 parts of mineral powder, 70 parts of fly ash, 700 parts of sand, 210 parts of coarse agg...

Embodiment 2

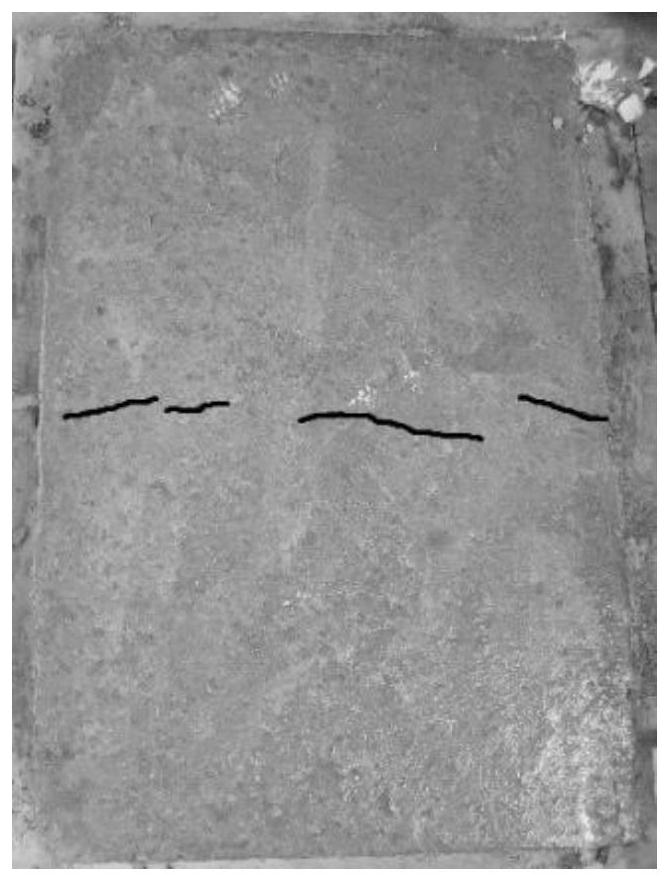

[0037] The concrete prepared in Example 1, whose slump and expansion both meet the pumping requirements, was tested by the plate method, and a large number of cracks appeared. After several tests, it was found that the addition of polypropylene fibers improved its crack resistance.

[0038] Table 1 shows the physical properties of the polypropylene fiber used in the present invention. The polypropylene fiber 1 is from Beijing Rongnaier Engineering Materials Co., Ltd., the polypropylene fiber 2 is from Jiangsu Nantong Syntigram Monofilament Technology Co., Ltd., and the polypropylene fiber 3 is from Ningbo Produced by Dacheng New Materials Co., Ltd., it is a wavy, double-sided twill-type coarse polypropylene fiber.

[0039] Table 1 Polypropylene fiber physical properties

[0040]

[0041] Embodiment 2: be made up of the following components by weight: 300 parts of cement, 150 parts of mineral powder, 50 parts of fly ash, 664 parts of sand, 268 parts of coarse aggregate one,...

Embodiment 3

[0042] Embodiment 3: be made up of the following components by weight: 310 parts of cement, 150 parts of mineral powder, 50 parts of fly ash, 664 parts of sand, 268 parts of coarse aggregate one, 824.8 parts of coarse aggregate two, 168 parts of water, 6.6 parts of water reducer, 8 parts of preservative, 0.9 part of polypropylene fiber 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com