Multi-nozzle methanol injector assembly structure

An assembly structure and injector technology, which is applied to fuel injection devices, machines/engines, engine components, etc., can solve problems such as poor anti-vibration ability, low durability life, and unstable dimensions, so as to ensure durability reliability and size Stability, reduced production costs, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

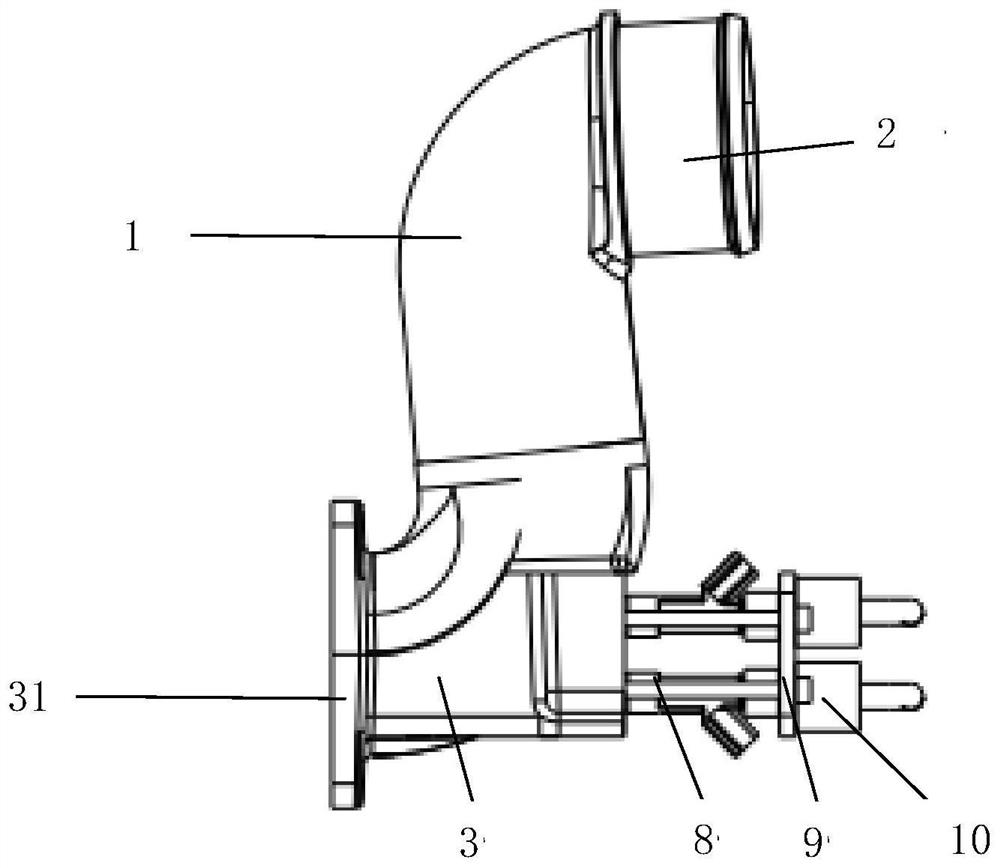

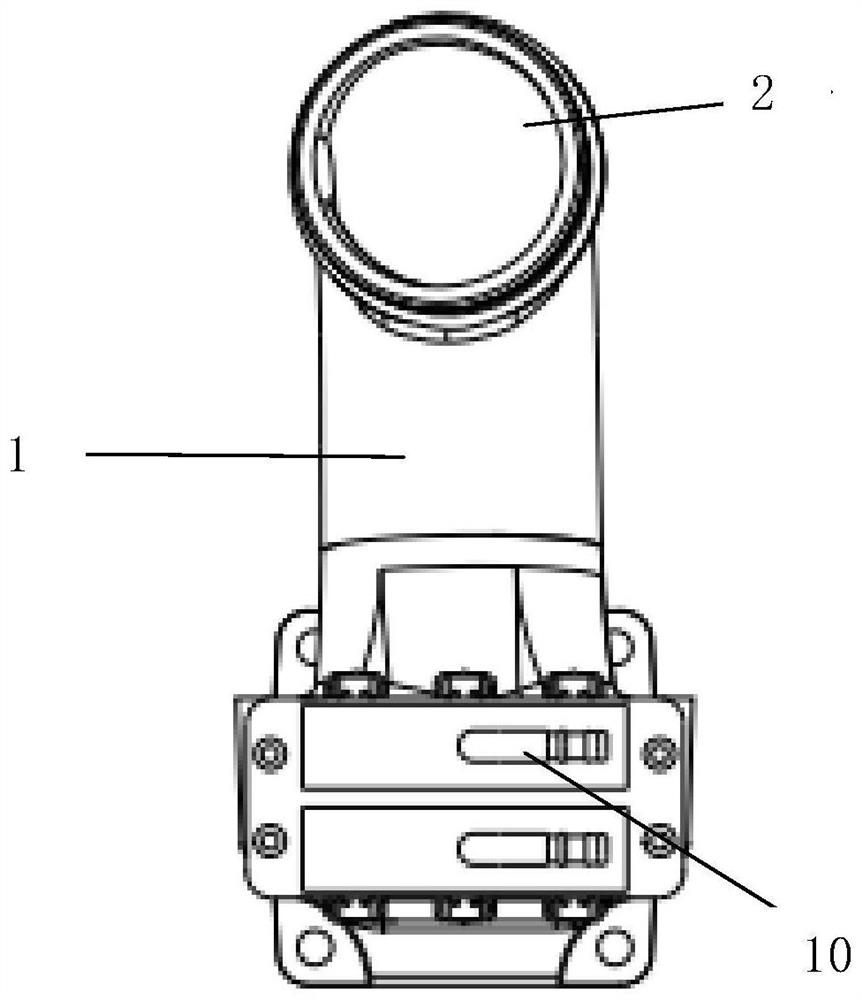

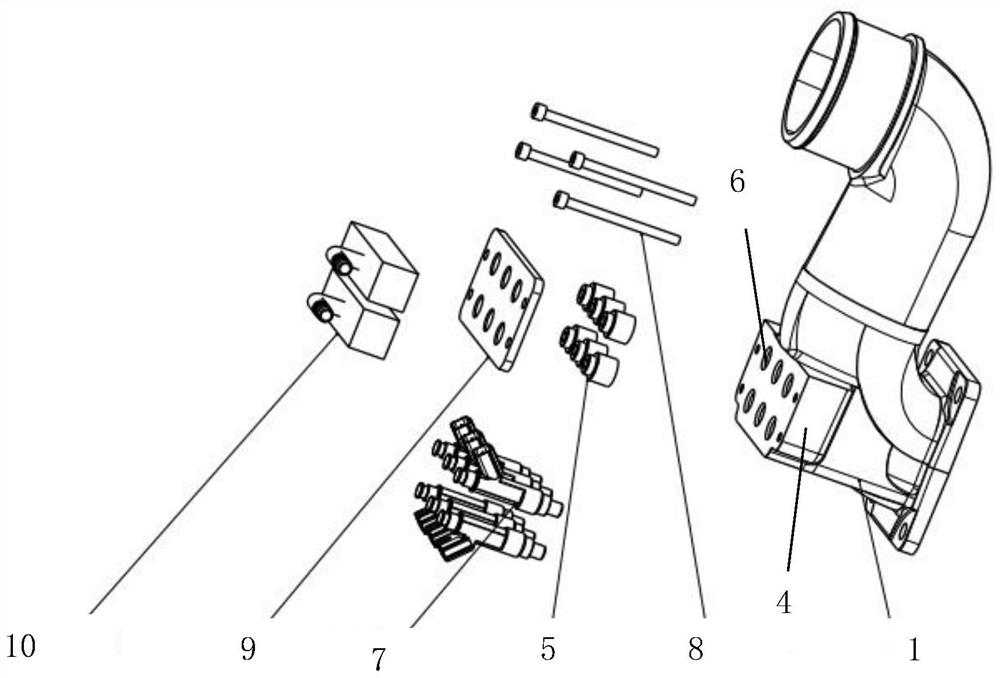

[0027] as attached Figure 1-3 As shown, a multi-nozzle methanol injector assembly structure includes an alcohol injector body 1, and the alcohol injector body 1 is respectively provided with an air inlet 2 and an air outlet 3, and the alcohol injector inside the air outlet 3 The body 1 is provided with an injector assembly mechanism, which sprays the external methanol gas into the alcohol injector body 1, and ensures that its injection direction is consistent with that in the alcohol injector body 1. The direction of gas flow is consistent.

[0028] The injector assembly mechanism of this embodiment includes a base 4 die-casted on the alcohol injector body 1, the base 4 is provided with a through hole 6 for accommodating the alcohol rail oil cup 5, and the alcohol rail The oil cup 5 is embedded in the through hole 6, the alcohol rail oil cup 5 is connected with the alcohol spray nozzle 7, and the base 4 is also connected with the alcohol rail flange 9 through the bolt 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com