High-precision waveform inversion system

A waveform inversion, high-precision technology, applied in circuit breaker testing, measuring devices, instruments, etc., can solve the technical difficulty, the primary and secondary fusion intelligent switch fault action accuracy rate is not effective, can not be used on-site primary fault Waveform and other issues to achieve high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

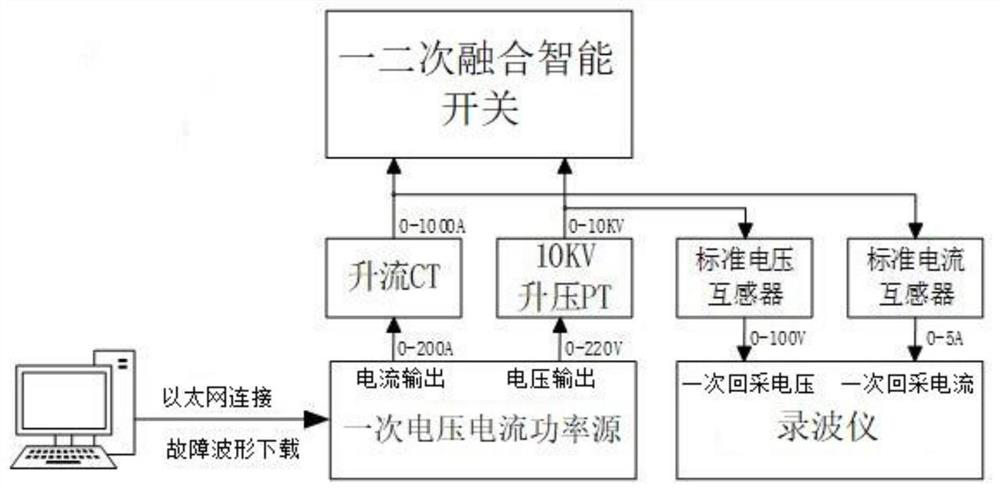

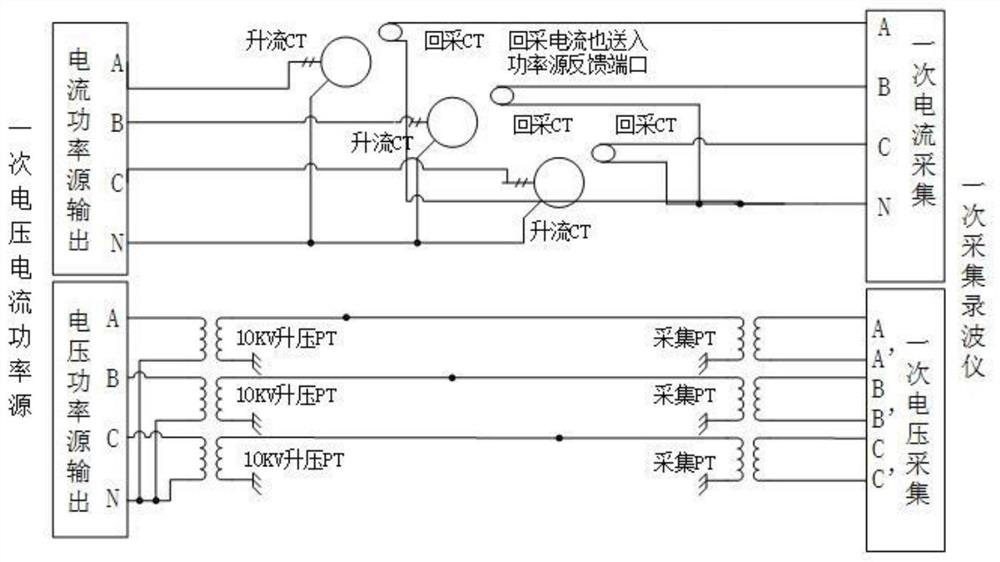

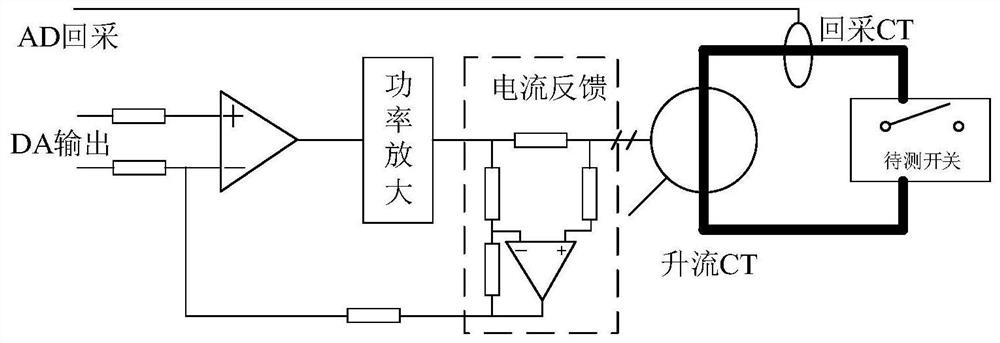

[0073] Such as Figure 1-Figure 5 As shown, a high-precision waveform inversion system hardware design, the design is: the waveform inversion system control software is installed on the workstation, connected to the primary voltage and current power source through Ethernet; the workstation control waveform inversion control software is issued The on-site fault waveform is sent to the primary voltage and current power source, and the primary voltage and current power source converts the digital signal into an analog signal output, and obtains a fault waveform through the power amplifier; in order to ensure that the output waveform is consistent with the set waveform, this embodiment adopts high-precision recording The oscilloscope performs high-precision and high-speed real-time sampling. After several cycles of calculation, the actual output waveform is compared with the set waveform, and then the output signal is corrected to ensure the consistency between the output signal an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com