Preparation method of insulated gate bipolar transistor

A technology of bipolar transistors and insulated gates, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve the problems of easy fragmentation, expensive equipment, and easy rupture, so as to reduce fragmentation and eliminate cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

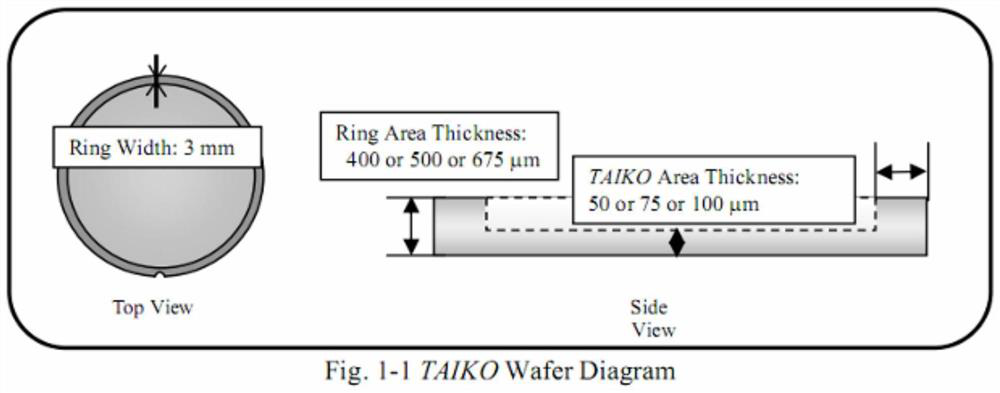

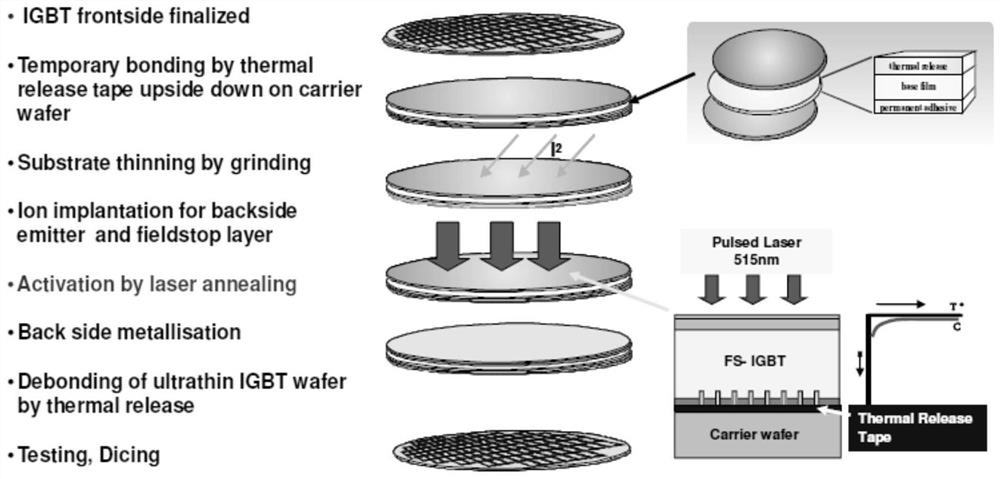

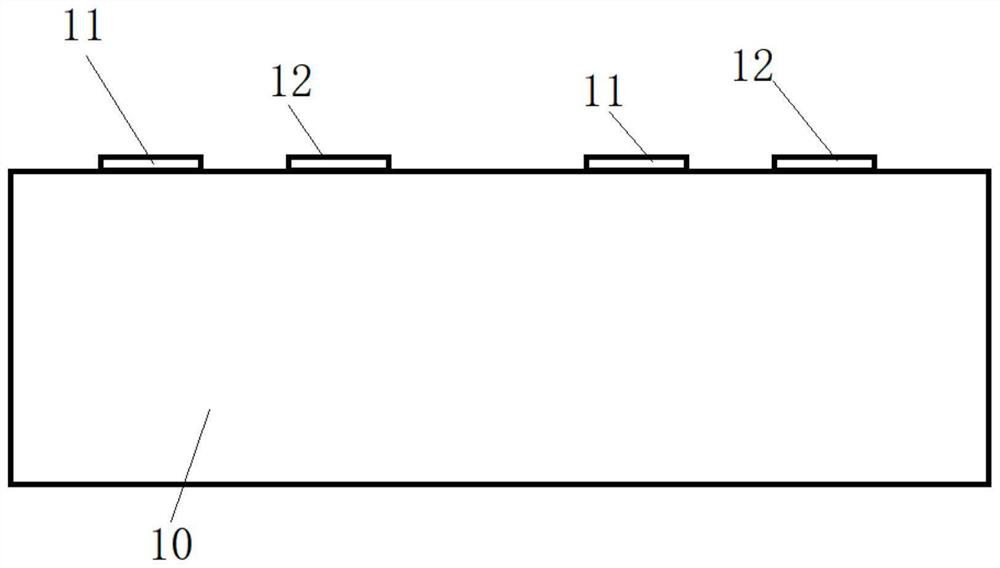

[0026] see Figure 3 to Figure 8 , the preparation method of the insulated gate bipolar transistor of the present invention, after finishing the front process of the IGBT wafer, make the bump 20 on the pressure pads of the collector 11 and the gate 12 on the front side of the wafer 10 (see image 3 and Figure 4 ); the bump 20 is a copper pillar (Cu Pillar), a gold pillar (Gold Pillar) or a solder ball (Solder Ball). If it is a copper pillar (Cu pillar) or a gold pillar (Gold pillar), the height range of the copper pillar (Cu pillar) or gold pillar (Gold pillar) is 10-100um. If it is a solder ball (Solder Ball), the diameter of the solder ball is 50-400um.

[0027] see Figure 5 , and then perform wafer-level plastic sealing on the front side of the wafer 10 to form a plastic sealing layer 30, the thickness of the resin of the plastic seali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com