Bipolar plate runner with injection function, bipolar plate and fuel cell

A bipolar plate and flow channel technology, which is applied in the fields of bipolar plates, fuel cells, and bipolar plate flow channels, can solve problems such as difficult processing, large gas flow resistance, and performance degradation of fuel cells, and achieve easy processing and low cost. Low, easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

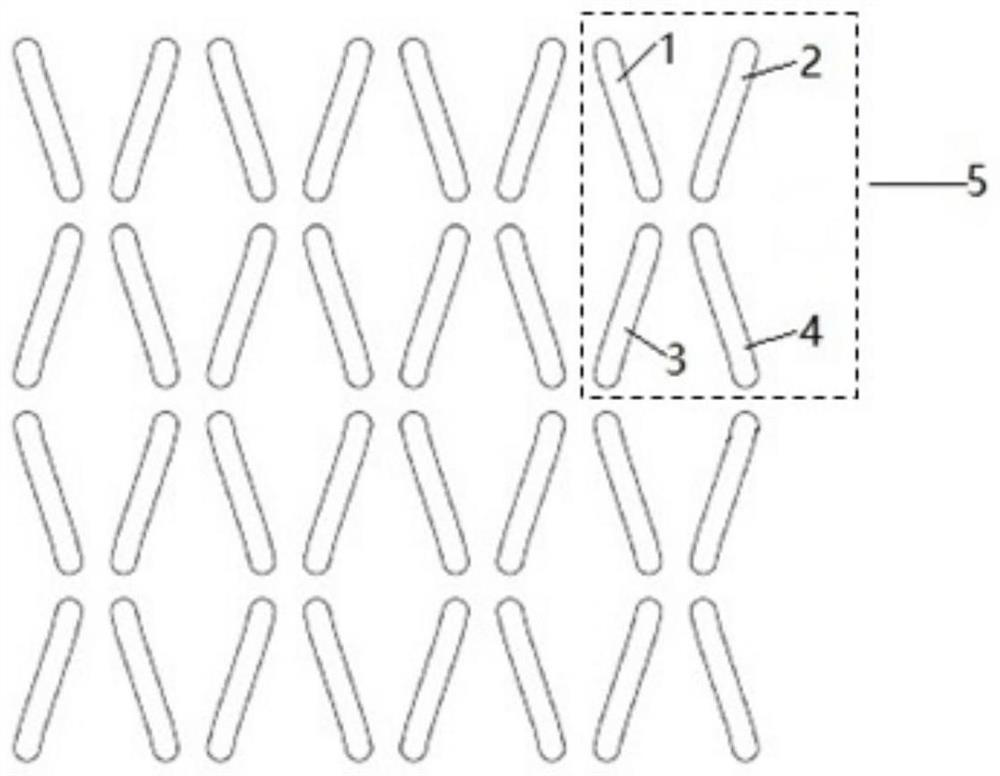

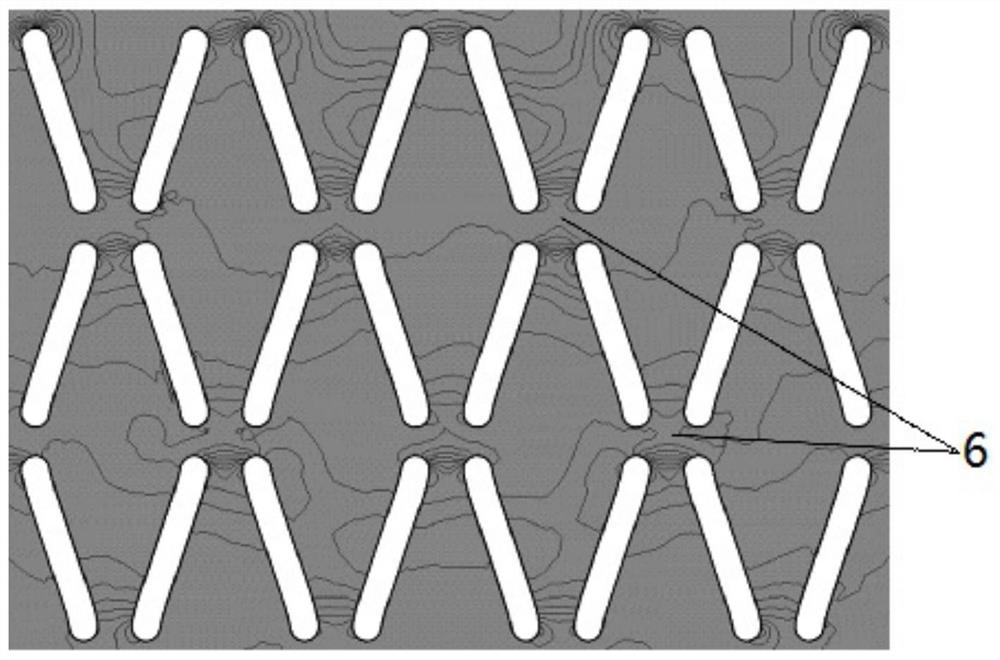

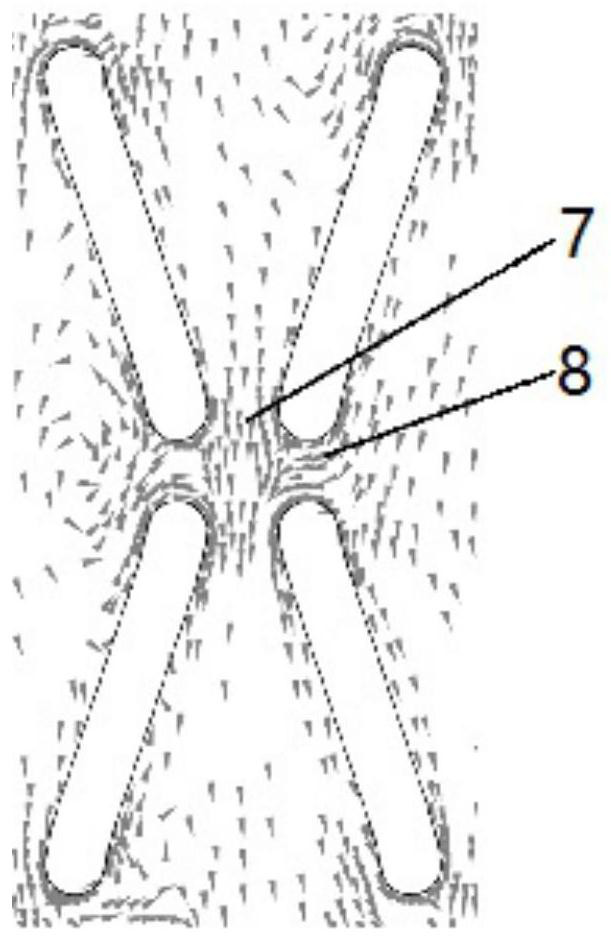

[0031] like figure 1 As shown, the present invention provides a bipolar plate, which includes a bipolar plate flow channel composed of a V-shaped structure and an inverted V-shaped structure. The V-shaped structure and the inverted V-shaped structure are in an axisymmetric relationship. The runner ridges are short rod-shaped. The first runner ridge 1 , the second runner ridge 2 , the third runner ridge 3 and the fourth runner ridge 4 form a basic unit 5 . One end of the first flow channel ridge 1 and one end of the second flow channel ridge 2 point to the center of the basic unit 5, so that the first flow channel ridge 1 and the second flow channel ridge 2 are V-shaped structures with openings at sharp corners; the third flow channel One end of the channel ridge 3 and one end of the fourth channel ridge 4 point to the center of the basic unit 5, so that the third channel ridge 3 and the fourth channel ridge 4 have an inverted V-shaped structure with openings at sharp corners...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com