Parallel SiC-MoS drive circuit of servo system

A servo system and drive circuit technology, applied in emergency protection circuit devices, electrical components, high-efficiency power electronic conversion, etc., can solve problems such as limited performance improvement space, and achieve the effect of high reliability characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

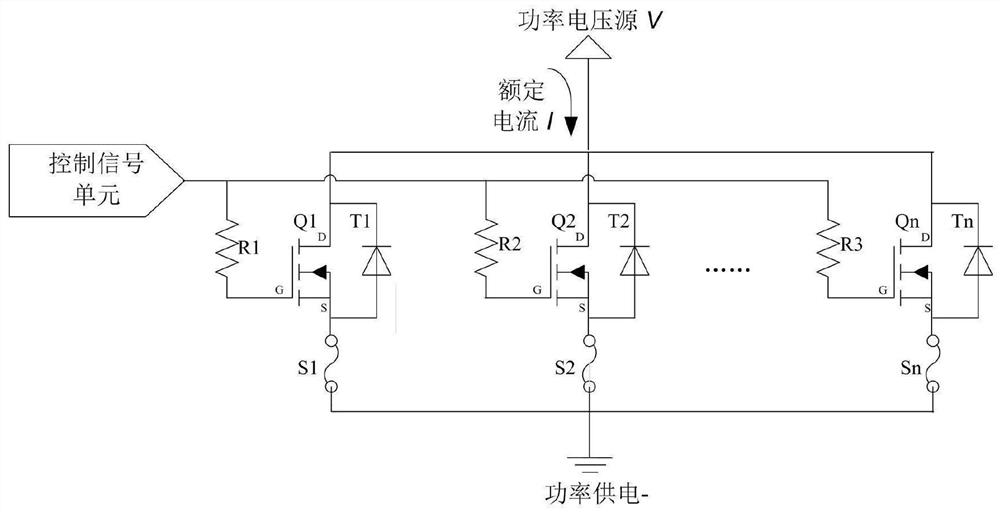

[0019] The invention is a high-reliability and high-energy-efficiency servo system parallel SiC-MoS driving circuit. The drive circuit provides a hardware basis for the new topology of SiC-MoS devices, high-frequency high-speed switch drive control, real-time short-circuit fault isolation technology, high-frequency driver electromagnetic compatibility design, etc. The block diagram of hardware structure of the present invention is as figure 1 As shown, the hardware circuit includes six parts including a control signal unit, a power voltage source V, n SiC-MoS devices Q, n gate resistors R, n freewheeling diodes T, and n fuses S.

[0020] The connections between the parts are as figure 1 As shown, the power voltage source V is provided by the servo system to generate the rated current I required by the entire drive circuit; according to the working requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com