Full-soluble edible mushroom protein and preparation method thereof

A technology of edible fungus and mycoprotein, which is applied in the direction of protein food ingredients, microbial protein composition, medical preparations containing active ingredients, etc. It can solve problems such as difficult to overcome the negative impact of protein structure, and achieve novel preparation principles and low energy consumption , the effect of low turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A fully soluble edible mushroom protein, the preparation method of which comprises the following steps:

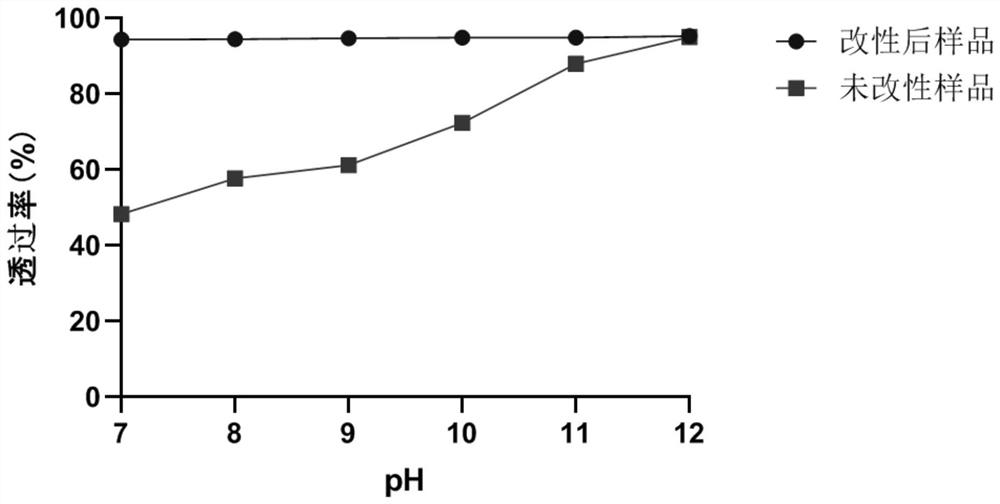

[0042] (1) Extraction of unmodified protein: crush the remaining Pleurotus eryngii roots and stems after picking with a blade grinder, pass through an 80-mesh sieve, and then mix the powder with deionized water at a ratio of 1:10 (w / v) Mixed, and adjusted to pH 12 with 1mol / L NaOH, stirred at room temperature for 4 hours. Then, centrifuge at 10,000×g and 4°C for 30 minutes, and collect the supernatant. Next, the pH of the supernatant was adjusted to 3.6 with 1 mol / L HCl under agitation, and after centrifugation at 10000×g and 4° C. for 20 minutes, the precipitate was collected. The collected protein was washed three times with deionized water, dispersed with appropriate amount of deionized water, and adjusted to pH 7 with 1mol / L NaOH. After freeze-drying, the unmodified Pleurotus eryngii protein was obtained.

[0043] (2) After mixing the unmodified Pleurotus ery...

Embodiment 2

[0051] A preparation method of fully soluble edible mushroom protein, comprising the following steps:

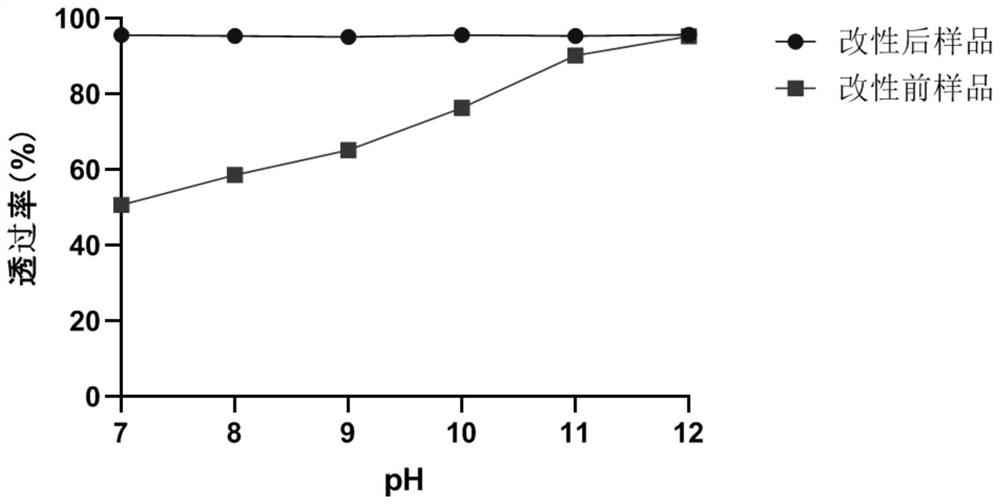

[0052] (1) Extraction of unmodified protein: crush the remaining shiitake mushroom roots and stems after picking with a blade grinder, pass through an 80-mesh sieve, and then mix the powder with deionized water at a ratio of 1:10 (w / v). After adjusting it to pH 12 with 1mol / L NaOH, it was stirred at room temperature for 4 hours. Then, centrifuge at 10,000×g and 4°C for 30 minutes, and collect the supernatant. Next, the pH of the supernatant was adjusted to 4.4 with 1 mol / L HCl under agitation, and after centrifugation at 10000×g and 4° C. for 20 minutes, the precipitate was collected. The collected protein was washed three times with deionized water, dispersed with appropriate amount of deionized water, and adjusted to pH 7 with 1mol / L NaOH. After freeze-drying, the unmodified mushroom protein is obtained.

[0053] (2) Mix the unmodified mushroom protein prepared in step ...

Embodiment 3

[0060] A preparation method of fully soluble edible mushroom protein, comprising the following steps:

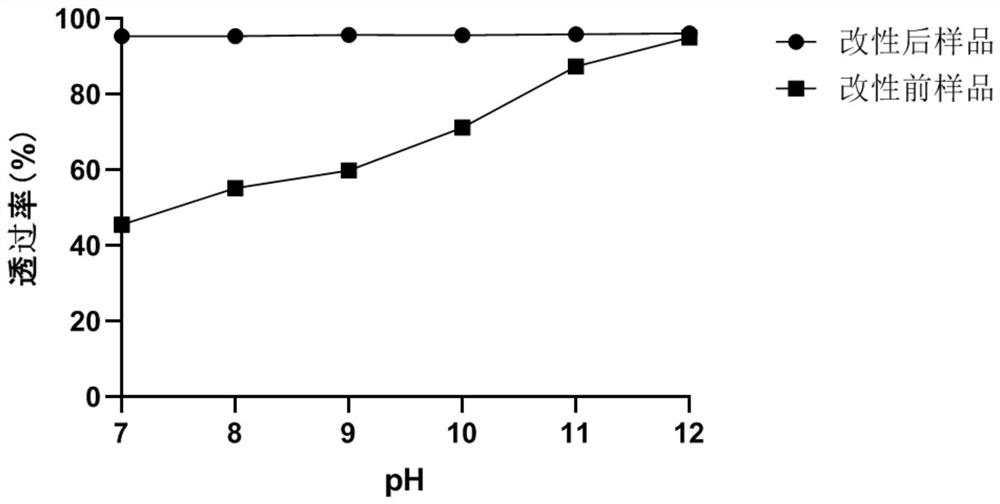

[0061] (1) Extraction of unmodified protein: the remaining Hericium erinaceus roots and stems after picking are crushed with a blade grinder and passed through an 80-mesh sieve, and then the powder and deionized water are mixed in a mass ratio of 1:10 (w / v) Mixing and adjusting the pH to 12 with 1 mol / L NaOH, stirring at room temperature for 4 hours. Then, centrifuge at 10,000×g and 4°C for 30 minutes, and collect the supernatant. Next, the pH of the supernatant was adjusted to 3.0 with 1 mol / L HCl under agitation, and after centrifugation at 10000×g and 4° C. for 20 minutes, the precipitate was collected. The collected protein was washed three times with deionized water, dispersed with appropriate amount of deionized water, and adjusted to pH 7 with 1mol / L NaOH. After freeze-drying, the unmodified Hericium erinaceus protein is obtained.

[0062] (2) After mixing the unm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com