Intelligent all-tailing sand thickener device and system

A thickener and full tailings technology, which is applied to the feeding/discharging device of the sedimentation tank, the sedimentation tank, chemical instruments and methods, etc. problems, to achieve the effect of reducing the workload of manual work, improving the response speed, and improving the level of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

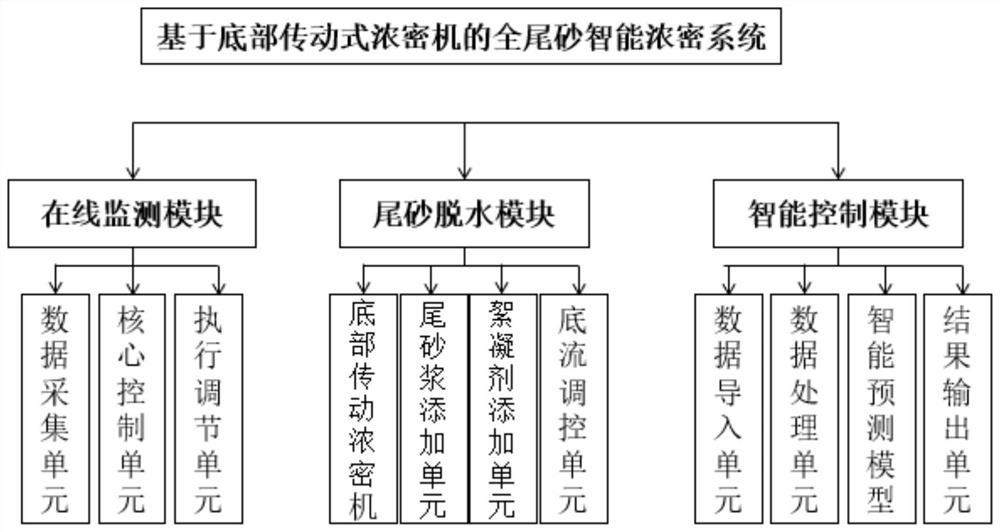

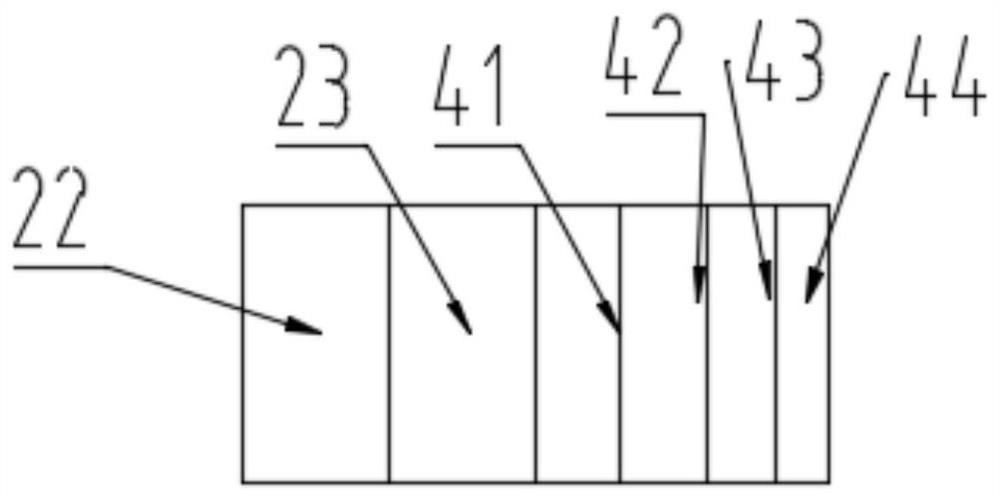

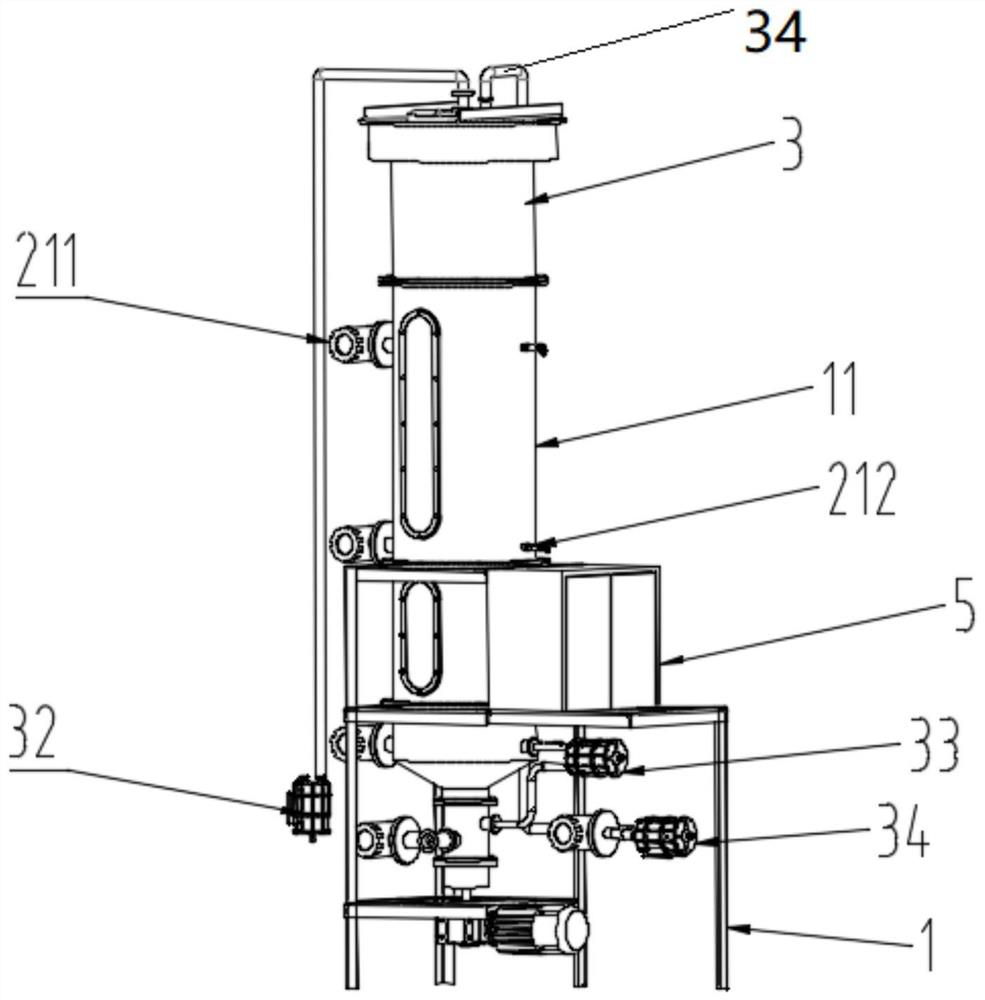

[0038] Such as figure 1 As shown, the present embodiment provides a whole tailings intelligent thickener device and system, including an online monitoring module 2 installed on a frame 1, a tailings dehydration module 3 and an intelligent control module 4, and the online monitoring module 2 includes data acquisition Unit 21, core control unit 22 and execution adjustment unit 23, the tailings dehydration module 3 includes a bottom drive thickener 31, a flocculant addition unit 32, an underflow control unit 33 and a tailings slurry addition unit 34, the intelligent control module 4 includes a data import unit 41, a data processing unit 42, an intelligent prediction unit 43 and a result output unit 44, the online monitoring module 2, the tailings dehydration module 3 and the intelligent control module 4 are connected in series in sequence, and the online monitoring The module 2 and the intelligent control module 4 perform real-time monitoring and control on the tailings dehydrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com