A kind of photo-assisted thermal catalyst and its preparation method and application

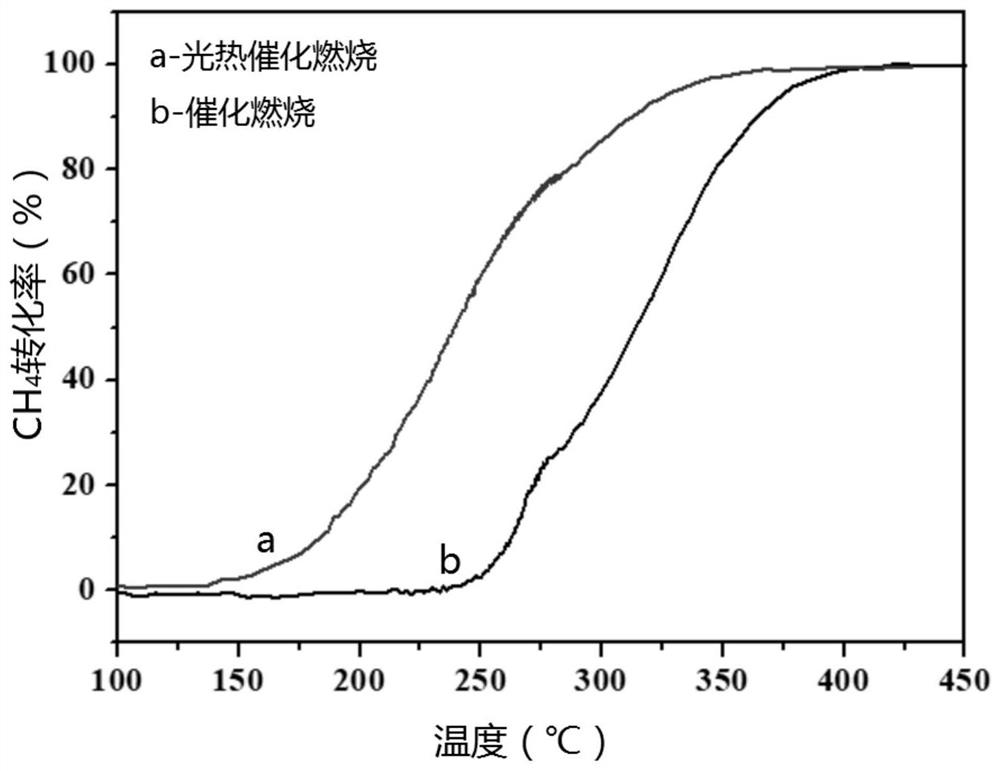

A light-assisted and catalyst technology, applied in the field of light-assisted thermal catalyst and its preparation, can solve the problem that the light-off temperature is difficult to further reduce, achieve good oxygen storage and release performance, improve performance, and facilitate the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

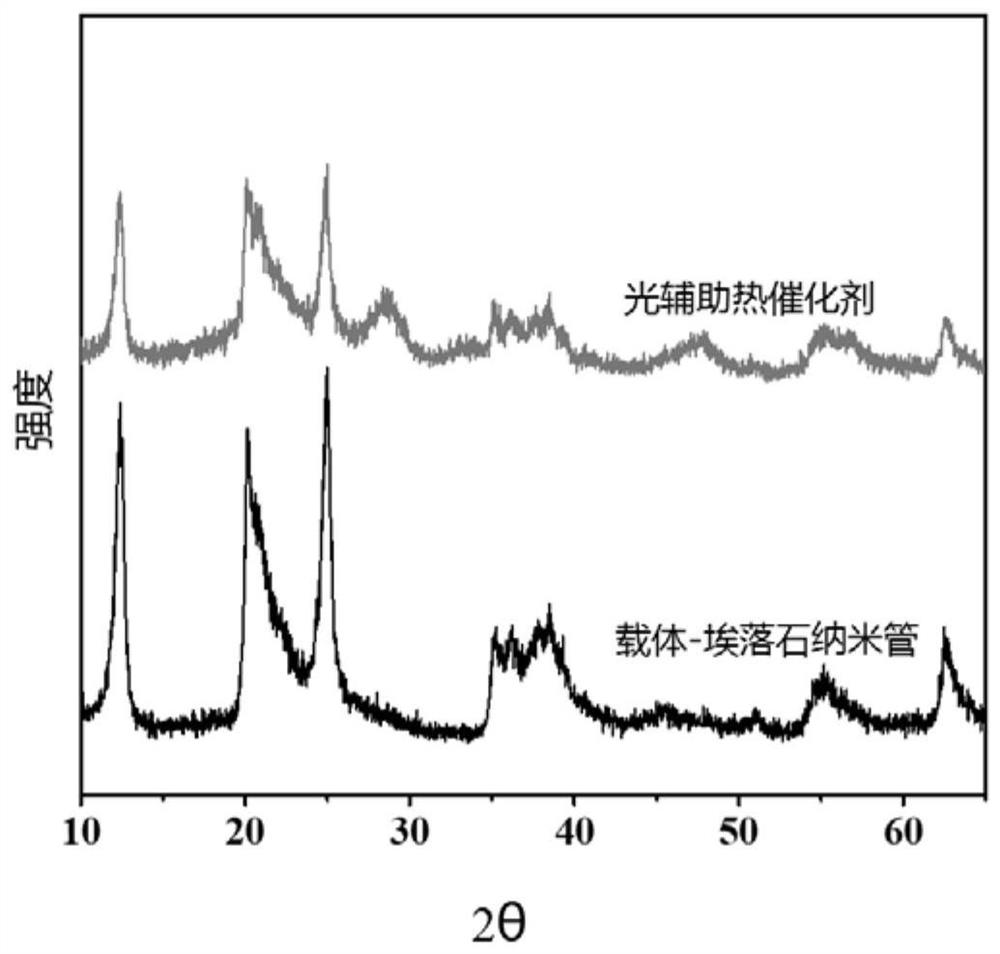

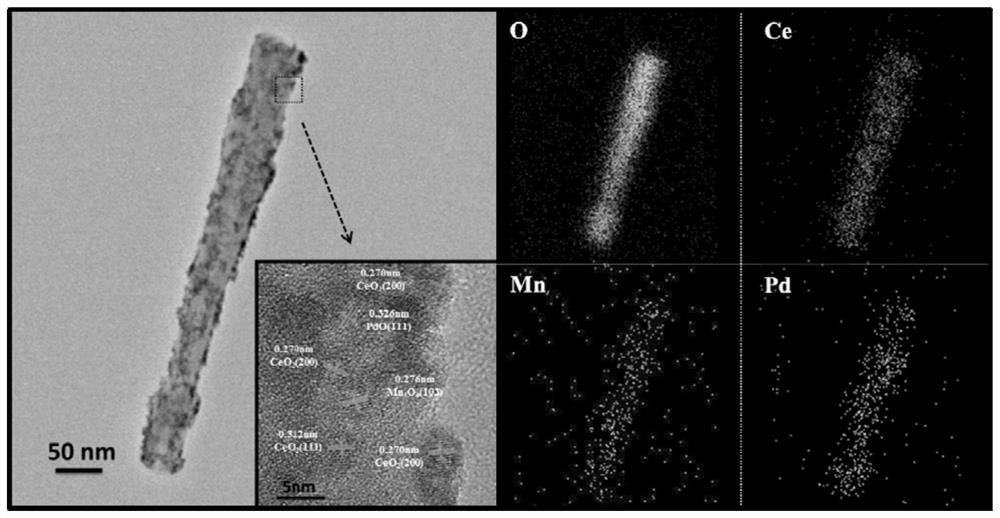

[0041] This embodiment provides a photo-assisted thermal catalyst, which includes a first active component, a second active component and a carrier, the first active component is Ce and Pd, the second active component is Mn, and the carrier is elkite nanometer Tubes (HNTs).

[0042] The preparation method of the above-mentioned light-assisted thermal catalyst comprises the following steps,

[0043] Take 2g angstrom nanotubes, disperse them in 200ml deionized water, heat the water bath to 30°C, and then bubbling argon to exhaust the air for 30min, add 1mmol / ml 1ml Ce(NO) 3 ) 3 Aqueous solution, then add 1mmol / ml 1ml NaOH aqueous solution, adjust pH to 10, after stirring evenly, add 0.1mmol / ml 0.5ml KMnO in turn 4 Aqueous solution and 2mmol / ml 0.5mlPd(NO 3 ) 2 aqueous solution. Under the protective atmosphere of argon, stir at room temperature for 60 minutes to obtain a precipitate, which is centrifuged, washed and dried, and then sintered at a high temperature of 500 °C fo...

Embodiment 2

[0049] This embodiment provides a photo-assisted thermal catalyst, which includes a first active component, a second active component and a carrier, the first active component is Ce and Pd, the second active component is Mn, and the carrier is elkite nanometer Tubes (HNTs).

[0050] The preparation method of the above-mentioned light-assisted thermal catalyst comprises the following steps,

[0051] Take 1 g of angstrom nanotubes, disperse them in 100 ml of deionized water, heat the water bath to 30 °C, and then bubbling argon to exhaust the air for 30 min, and add 2 mmol / ml 1 ml Ce (NO 3 ) 3 Aqueous solution, then add 2mmol / ml 1ml NaOH aqueous solution, adjust pH to 10, after stirring evenly, add 0.2mmol / ml 0.5ml KMnO successively 4 Aqueous solution and 2mmol / ml 1ml Pd(NO 3 ) 2 solution. Under the protective atmosphere of argon, stir at room temperature for 60 minutes to obtain a precipitate. After the precipitate is centrifuged, washed, and dried, it is sintered at a hig...

Embodiment 3

[0053] This embodiment provides a photo-assisted thermal catalyst, which includes a first active component, a second active component and a carrier, the first active component is Ce and Pd, the second active component is Mn, and the carrier is elkite nanometer Tubes (HNTs).

[0054] The preparation method of the above-mentioned light-assisted thermal catalyst comprises the following steps,

[0055] Take 5g angstrom nanotubes, disperse them in 4000ml deionized water, heat the water bath to 30°C, and then bubbling argon to exhaust the air for 30min, add 1mmol / ml 1ml Ce(NO) 3 ) 3 Aqueous solution, then add 1mmol / ml 1ml NaOH aqueous solution, adjust pH to 10, after stirring evenly, add 0.1mmol / ml 0.5ml KMnO in turn 4 Aqueous solution and 2mmol / ml 0.5ml Pd(NO 3 ) 2 aqueous solution. Under an argon protective atmosphere, stir at room temperature for 60 minutes to obtain a precipitate. After the precipitate is centrifuged, washed and dried, it is sintered at a high temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com