Printed paper collecting vehicle

A technology for collecting carts and paper, which is applied in the field of printing and packaging, and can solve problems such as paper damage and paper deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

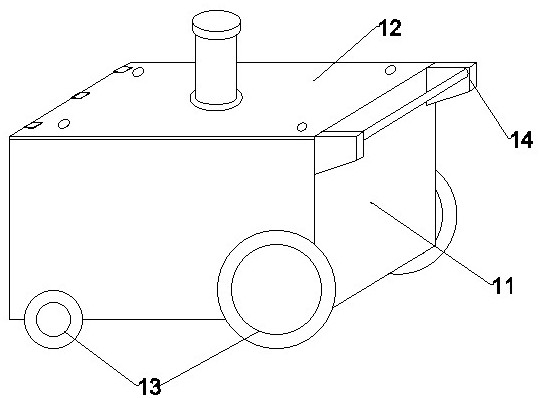

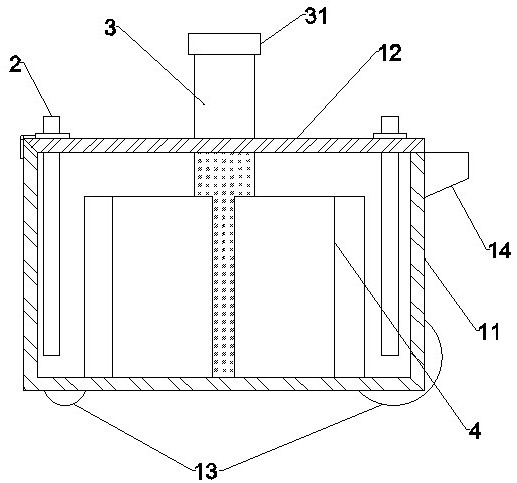

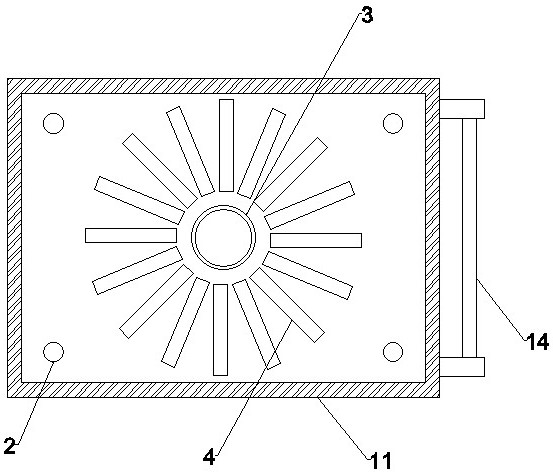

[0038] Such as figure 1 What is described is a printed paper collection vehicle, which is used to reduce the problem of easy damage in the transfer process of printed paper in the prior art, and can also be used as a paper storage container; its structure includes: a vehicle body, a control Wet pipe 2, combustion cylinder 3, and paper storage box 4. The paper storage box 4 is a tool for storing paper, which is convenient for users to collect paper on the printing production line, and can provide better protection for paper. Transport or temporarily store in the car body, the humidity control tube 2 is installed in the car body, the humidity in the interior space of the car body is adjusted through the humidity control tube 2, and it can be stored with paper, and the combustion tube 3 is detachable Installed in the car body, the paper is dried by the heat generated by combustion to promote the combination of ink and paper. At the same time, due to the consumption of oxygen duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com