SCR system downstream temperature sensor credibility fault diagnosis method

A temperature sensor and SCR system technology, applied in thermometers, thermometer testing/calibration, instruments, etc., can solve problems such as misdiagnosis, slow temperature rise response of temperature sensors, temperature rise differences, etc., to improve temperature rise responsiveness and reduce errors Effect of diagnosing risks and meeting monitoring requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

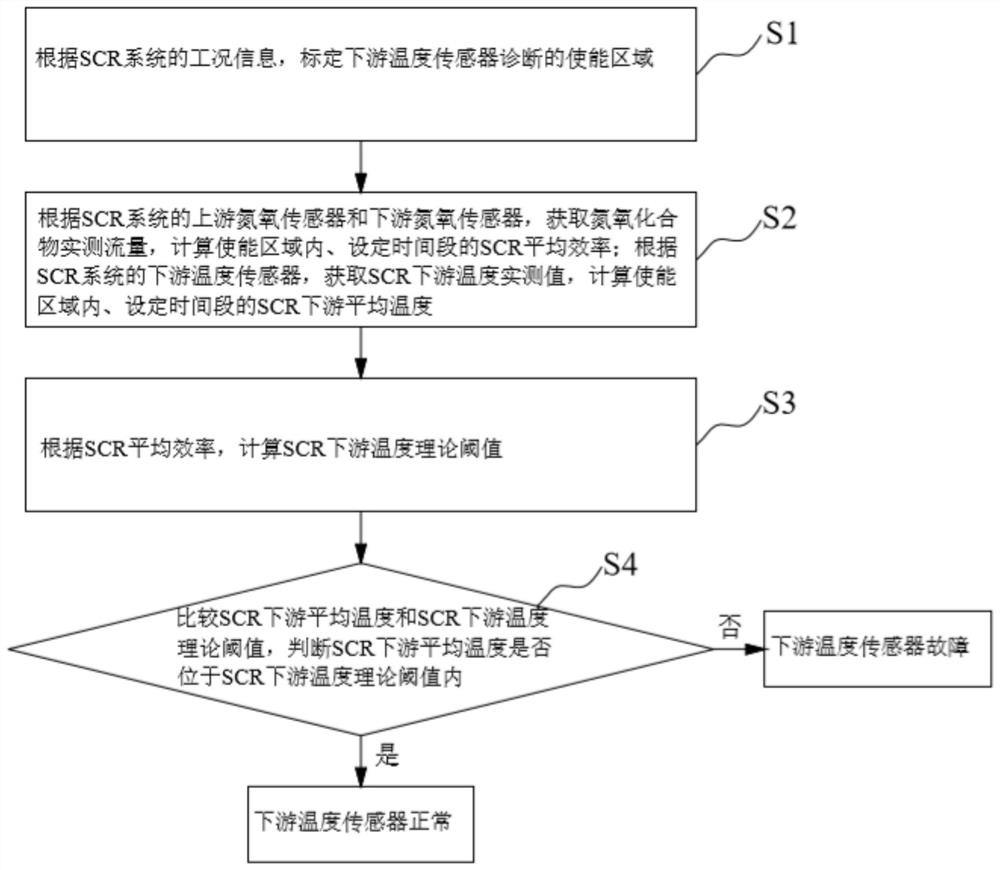

[0036] like figure 1 As shown, the embodiment of the present invention provides an SCR system downstream temperature sensor trusted fault diagnosis method, the SCR system as part of the engine post-processing system, informing the exhaust system of the engine, including the upstream nitrogen oxygen sensor, downstream nitrogen oxygen sensor, Upstream temperature sensor, downstream temperature sensor and SCR vector, and the like. The diagnostic method specifically includes the following steps:

[0037] Step S1, set the enable area of the downstream temperature sensor diagnosis according to the working condition information of the SCR system;

[0038]In this step S1, a first working process the main factors based SCR system, the downstream temperature sensor diagnostic setting for enabling area; SCR system condition information including environmental conditions and / or status conditions of the engine and / or the actuator status conditions and / or a sensor operating status condi...

Embodiment 2

[0059] Embodiment of the present invention provides a remote applications platform T-BOX calibration enable area, and the credibility of the fault diagnosis method using an SCR system downstream temperature sensor in the first embodiment of the method for enabling authentication area. Includes the following steps:

[0060] 1, using the T-BOX remote internet, collection vehicle nitrogen oxide sensor upstream of the SCR system, downstream of the nitrogen oxide sensor, the upstream temperature sensor and the measured values of the downstream temperature sensor during actual road;

[0061] 2, the above-described collected large amounts of data through large data cleaning, processing, to calculate the SCR conversion efficiency in the SCR average efficiency efficient region, upstream of the SCR average temperature, SCR downstream average temperature, SCR support has an average temperature, finalized after correction theoretical threshold temperature upstream of the SCR and downstream ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com