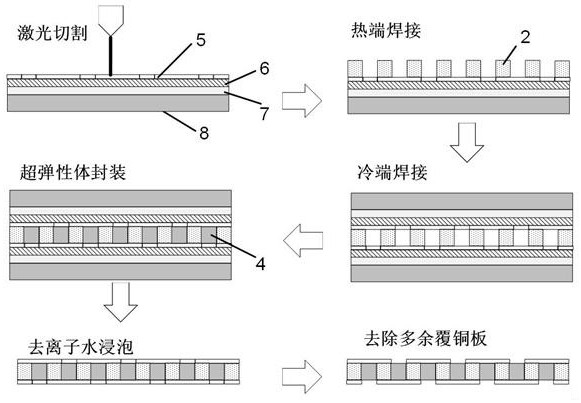

Stretchable flexible thermoelectric device and manufacturing method thereof

A technology for thermoelectric devices and fabrication methods, which are applied in the directions of thermoelectric devices, thermoelectric device manufacturing/processing, thermoelectric device components, etc., can solve the problem that errors are easily introduced in the device positioning process, large-area manufacturing and arraying are difficult, and device connection efficiency is low. and other problems, to avoid repeated positioning and welding problems, easy pattern replacement and adjustment, and improve heat transfer efficiency and output power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0070] When the load resistance is 5Ω, the output power and power density of the stretchable flexible thermoelectric device of this application vary with the temperature of the hot end. Figure 7 As shown, the ambient temperature of the cold end is 25°C, and the temperature of the hot end rises from 30°C to 80°C (the temperature difference is 5K~55K). As the temperature of the hot end increases, the output power and power density of the stretchable flexible thermoelectric device gradually increase. Under the condition of a temperature difference of 55K, the load power reaches 61.3 μW and the power density is 5 μW / cm 2 .

[0071] When the load resistance increases from 1Ω to 100Ω, the change curve of the output voltage and output power of the stretchable flexible thermoelectric device in this application (temperature difference ΔT=35K) is as follows Figure 8 As shown, as the external load resistance increases, the output voltage of the stretchable flexible thermoelectric devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com