Special battery heat dissipation device for new energy automobile

A technology for new energy vehicles and heat dissipation devices, which is applied in secondary batteries, battery pack components, circuits, etc., to achieve the effect of improving work capacity, accelerating heat dissipation, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

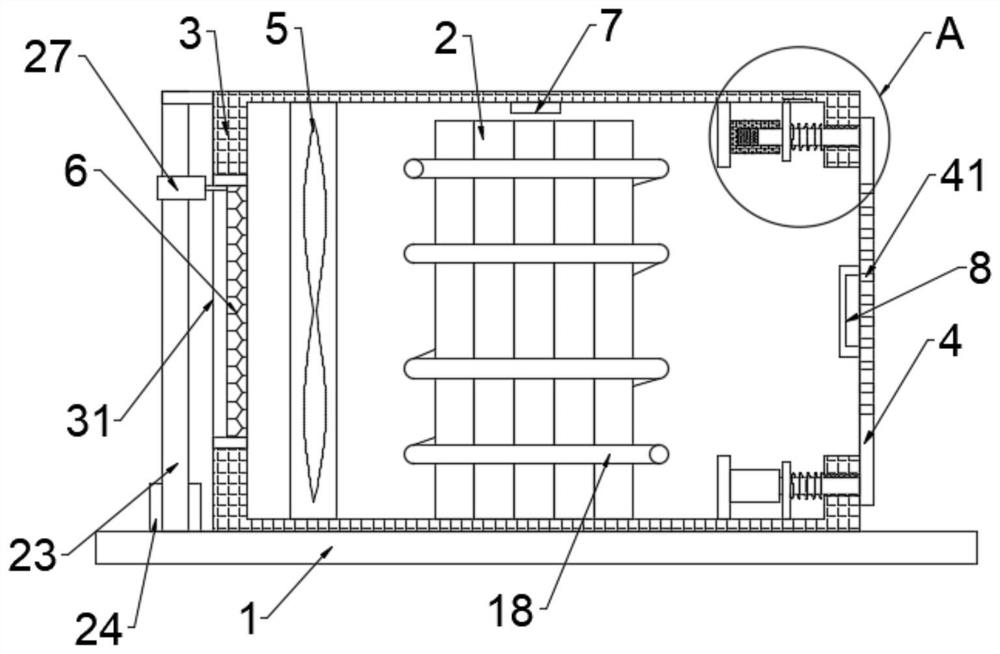

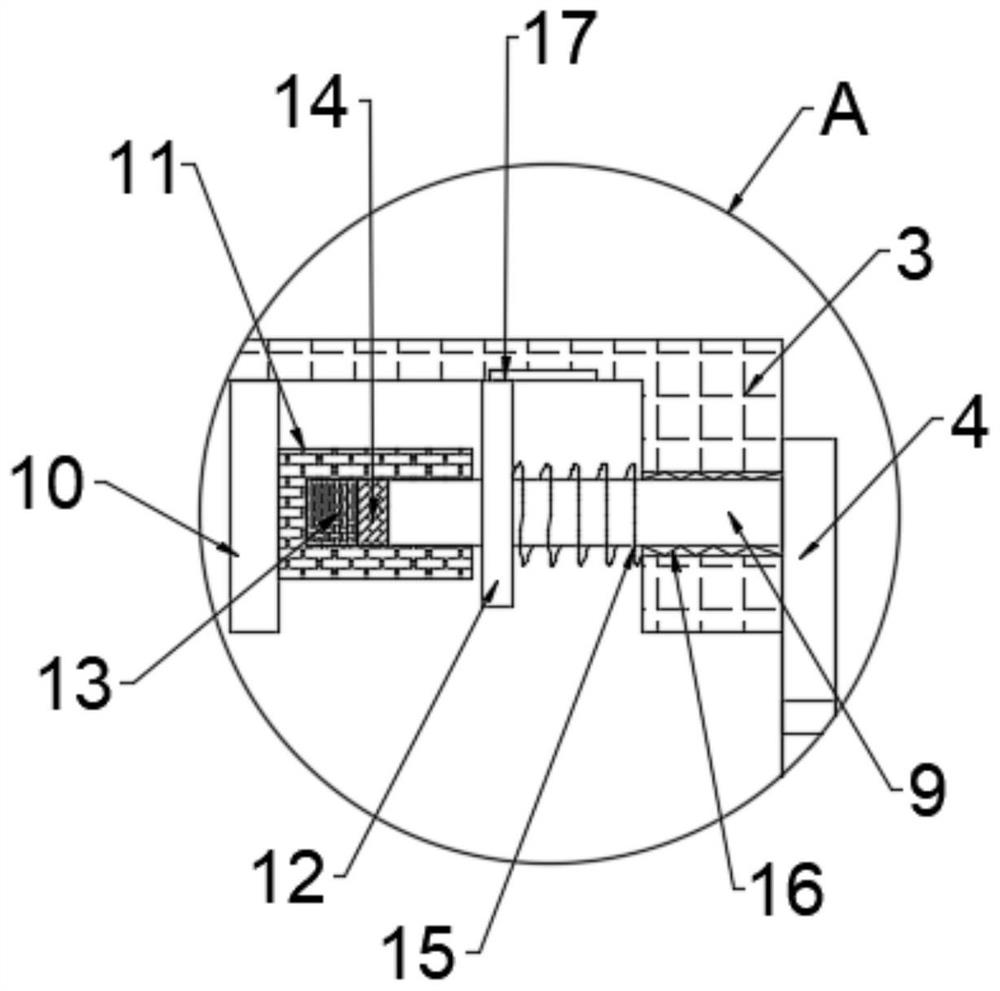

[0024] to combine Figure 1-5 , a special battery cooling device for new energy vehicles, including a mounting plate 1, a housing 3 and a battery pack 2, the housing 3 is fixed on the upper end of the mounting plate 1, the battery pack 2 is fixed inside the housing 3, the One side of the housing 3 is movably connected with a side plate 4, and the other side is provided with an air inlet slot 31, and the side plate 4 is provided with a heat dissipation hole 41, and the inside of the housing 3 is installed near the air inlet slot 31 A cooling fan 5, the air inlet groove 31 is connected with a filter screen 6, and the side plate 4 is fixed with a plurality of moving slide bars 9 near the side of the housing 3, and the moving slide bars 9 are connected to the side wall of the housing 3 Sliding connection, a plurality of first fixing plates 10 are fixed inside the housing 3 and close to the side plate 4, and sleeves 11 are connected to the plurality of first fixing plates 10, and t...

Embodiment 2

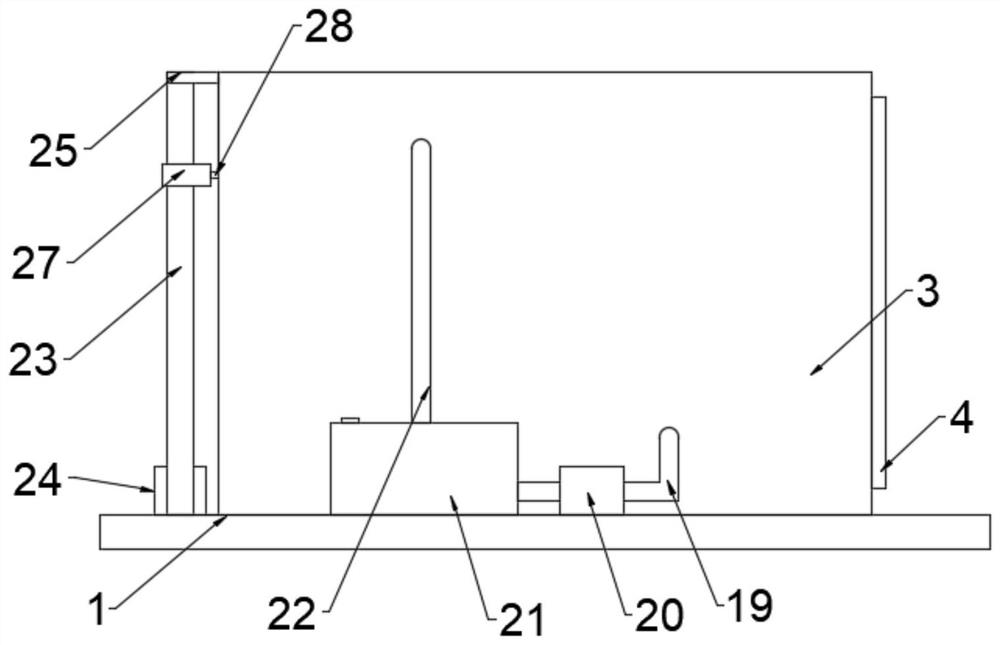

[0033] combine figure 1 , figure 2 and Figure 4 , a special battery cooling device for new energy vehicles. This embodiment further limits the present invention on the basis of Embodiment 1.

[0034] A second fixing plate 25 is connected to the side of the housing 3 and close to the filter screen 6, a threaded rod 26 and a limit rod 23 are arranged between the second fixing plate 25 and the mounting plate 1, and the threaded rod 26 and the Limiting rods 23 are respectively arranged on both sides of the filter screen 6, and one end of the threaded rod 26 is rotatably connected with the second fixed plate 25, and the other end is connected with the motor 24 transmission fixed on the upper end of the mounting plate 1. The limiting rods 23 The two ends are respectively fixedly connected with the second fixed plate 25 and the mounting plate 1, and the threaded rod 26 and the limit rod 23 are connected with a moving plate 27, and the moving plate 27 is threaded with the threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com