Automatic feeding clamp for waste circuit board desoldering equipment and method

A waste circuit board, automatic feeding technology, applied in welding equipment, metal processing equipment, solid waste removal, etc. Cost, solve the effect of slow feeding in large batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

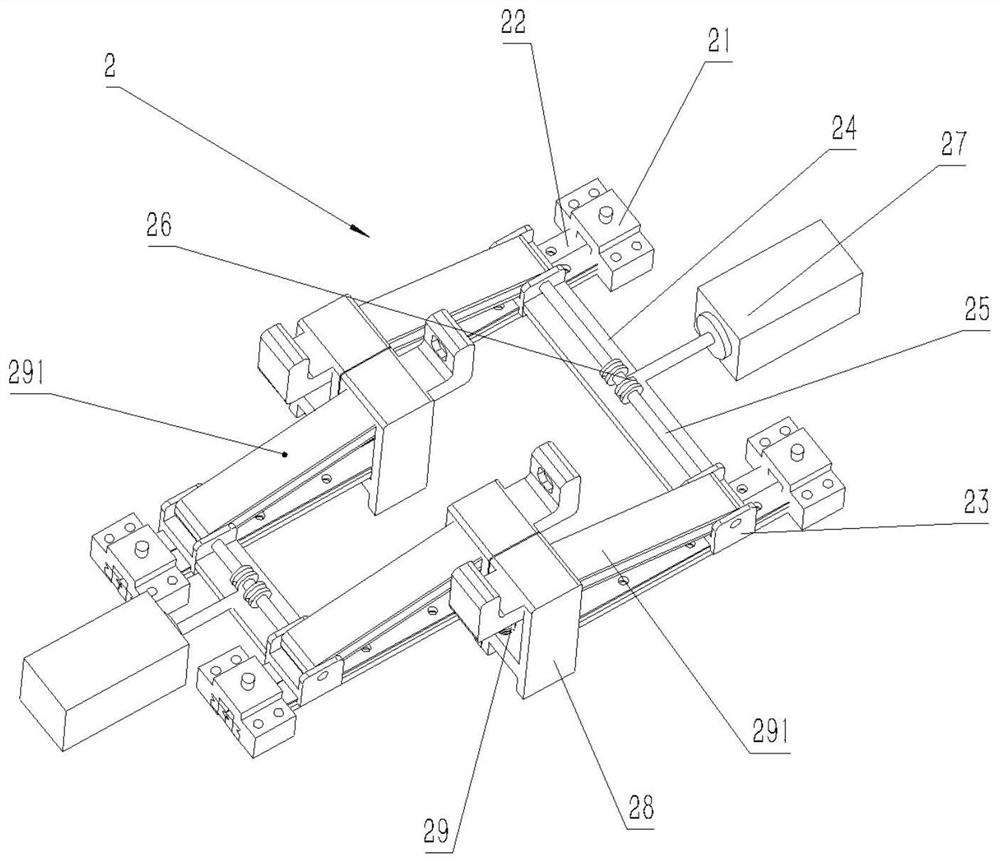

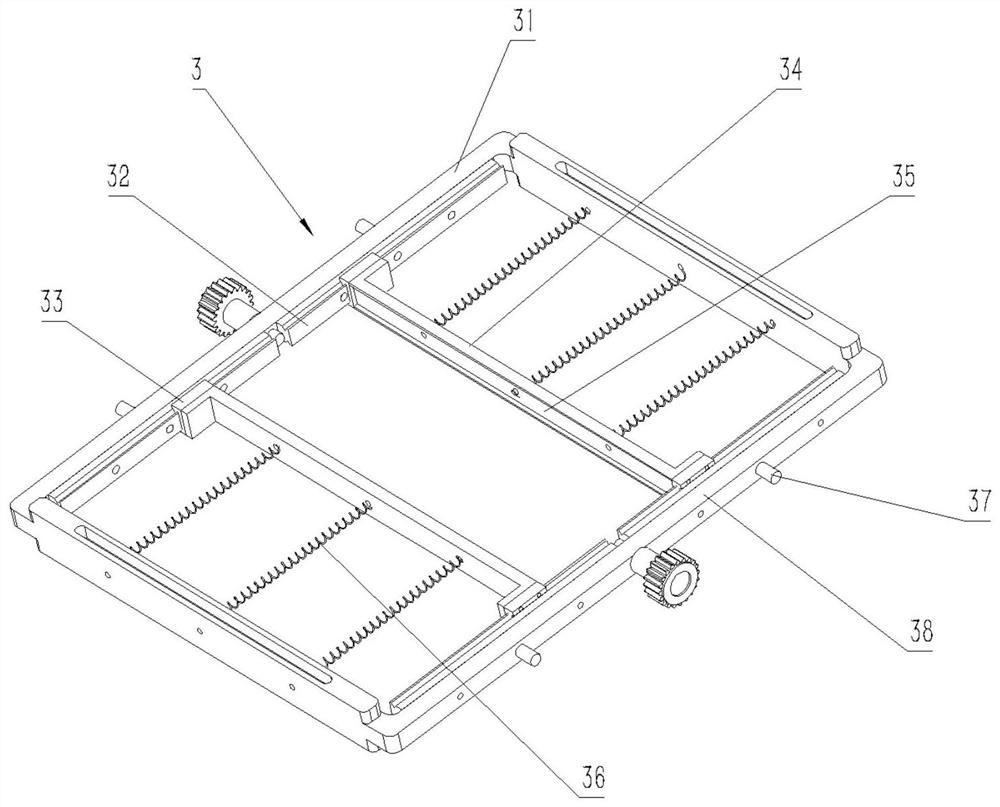

[0034] First put the unloaded clamp 3 into the clamp slide rail of the clamp feeding end 11 on the upper part of the automatic feeding frame 1, and the movement of the conveying mechanism 4 moves the clamping groove of the telescopic clamping mechanism 5 to the clamping groove column 37 of the clamping device 3 Directly below, the slot inside the retractable slot mechanism 3 lifts up the slot column 37 that clamps the clamp 3, the conveying mechanism 4 drives the clamp 3 to be transported to the top of the clamp opening and closing mechanism 2 and then stops, and the clamp opening and closing mechanism 2 pushes the clamp 3 is opened, and the discarded TV circuit board to be loaded is loaded into the clamp 3, the clamp opening and closing mechanism 2 is closed, and the conveying mechanism 4 drives the clamp 3 to convey forward, and an automatic feeding is completed. After testing, the discarded TV circuit board is It can automatically feed 3000 pieces.

Embodiment 2

[0036] First put the unloaded clamp 3 into the clamp slide rail of the clamp feeding end 11 on the upper part of the automatic feeding frame 1, and the conveying mechanism 4 starts to move the clamping slot of the telescopic clamping mechanism 5 to the clamping slot column 37 of the clamping device 3 Directly below, the slot inside the retractable slot mechanism 5 lifts up the slot column 37 that clamps the clamp 3, and the conveying mechanism 4 drives the clamp 3 to be transported directly above the clamp opening and closing mechanism 2 and then stops, and the clamp opening and closing mechanism 2 pushes the clamp 3 is opened, and the discarded tablet computer circuit board to be loaded is loaded into the fixture 3, the fixture opening and closing mechanism 2 is closed, and the conveying mechanism drives the fixture 3 to convey forward, and an automatic feeding is completed. After testing, the discarded tablet computer circuit board can be used every hour. Automatic feeding 36...

Embodiment 3

[0038] First put the unloaded clamp 3 into the clamp slide rail of the clamp feeding end 11 on the top of the automatic feeding frame 1, and the conveying mechanism 4 starts to move the clamping groove of the telescopic clamping groove mechanism 5 to the clamping groove column 37 of the clamping device. Below, the slot inside the retractable slot mechanism 5 lifts up the slot column 37 that clamps the clamp 3, and the conveying mechanism 4 drives the clamp 3 to be transported to the top of the clamp opening and closing mechanism 2 and then stops, and the clamp opening and closing mechanism 2 pushes the clamp 3 Open it, load the discarded mobile phone circuit boards to be loaded into the clamp 3, the clamp opening and closing mechanism 2 is closed, and the conveying mechanism 4 drives the clamp 3 forward to complete one automatic feeding. After testing, the discarded mobile phone circuit boards can be automatically loaded every hour. The material is 5400 yuan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com