Automatic feeding device for automobile hubs

A technology of automobile hubs and power devices, which is applied in the directions of packaging, transportation and packaging, and unstacking of objects, etc., can solve problems such as poor function, low efficiency, and heavy workload, and achieve good storage performance, good separation, and improved efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

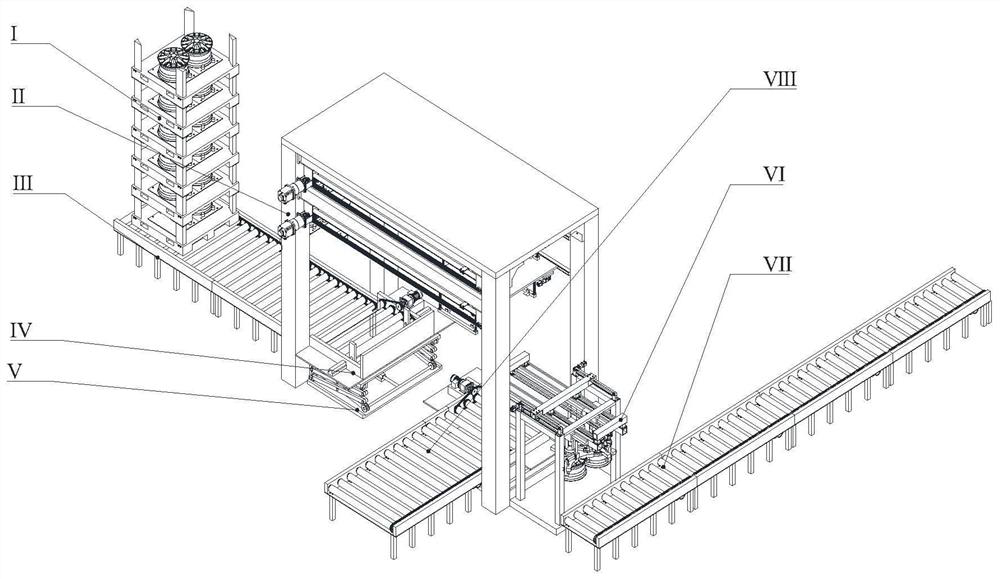

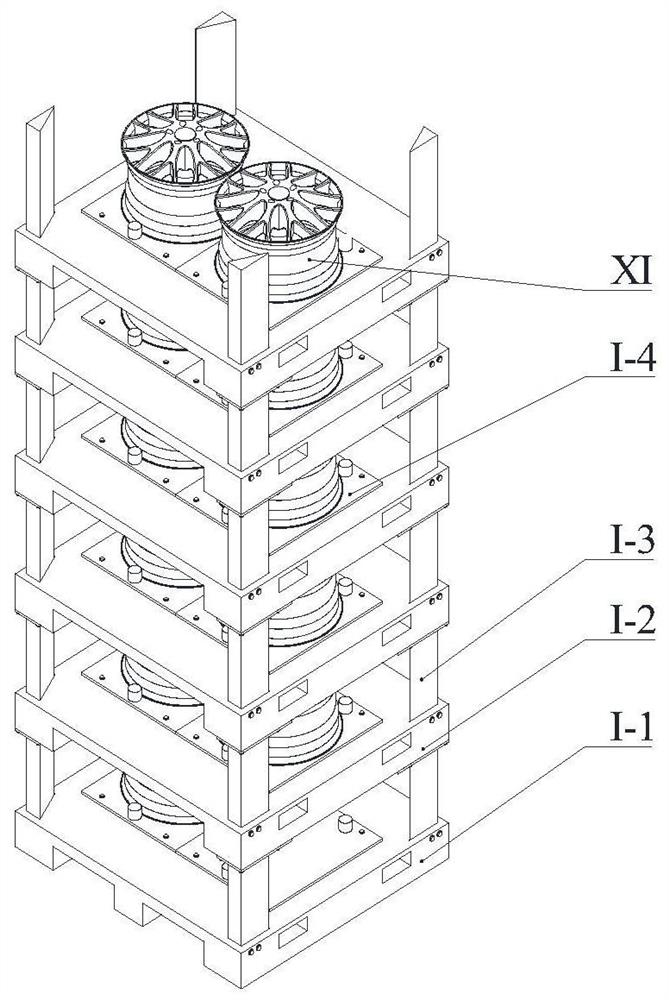

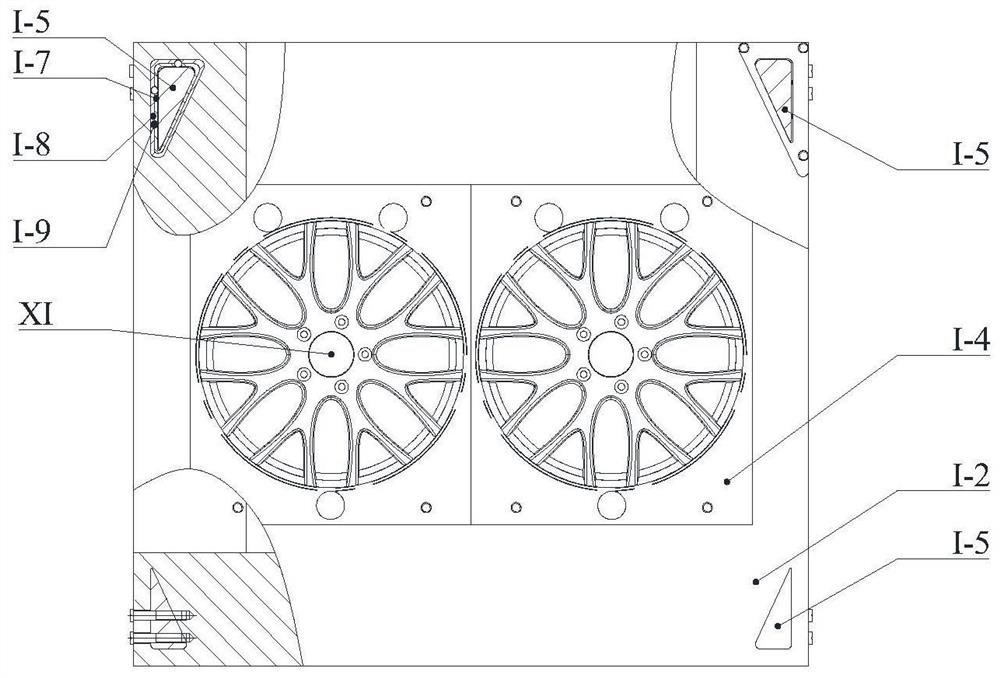

[0053] This embodiment provides a kind of auto wheel hub automatic feeding device, such as figure 1 As shown, it includes separable material rack I, material rack separation device II, first roller table III, second roller table IV, lifting table V, manipulator VI, third roller table VIII, fourth roller table VII, separable material Frame I is used for loading and unloading wheel hub XI, and the detachable material rack I is transported through the first roller table III; one end of the first roller table III is provided with the fourth roller table VII, and the lifting platform V is installed under the fourth roller table VII. The fourth roller table VII is located at the feeding end of the material rack separation device II, and the third roller table VIII is arranged at the discharge end of the material rack separating device II, and the transmission directions of the first roller table III and the third roller table VIII are perpendicular to each other. The fourth roller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com