Electric automation material automatic placing and positioning device

An electrical automation and positioning device technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of inability to adjust the position of materials, complicated operation of electrical automation equipment, etc., to improve service life, reduce use difficulty, and reduce wear speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

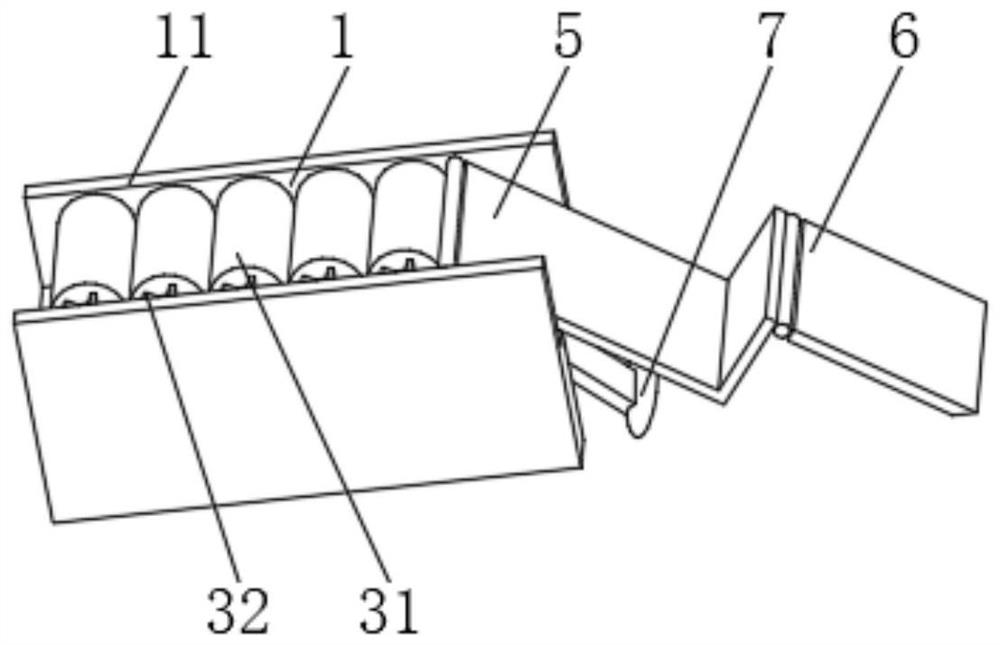

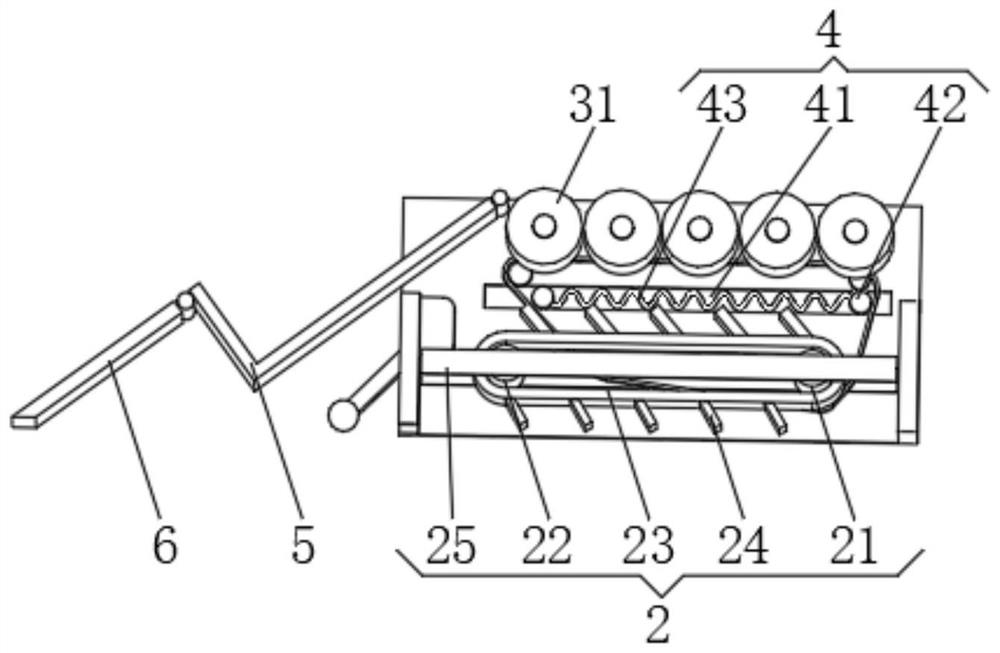

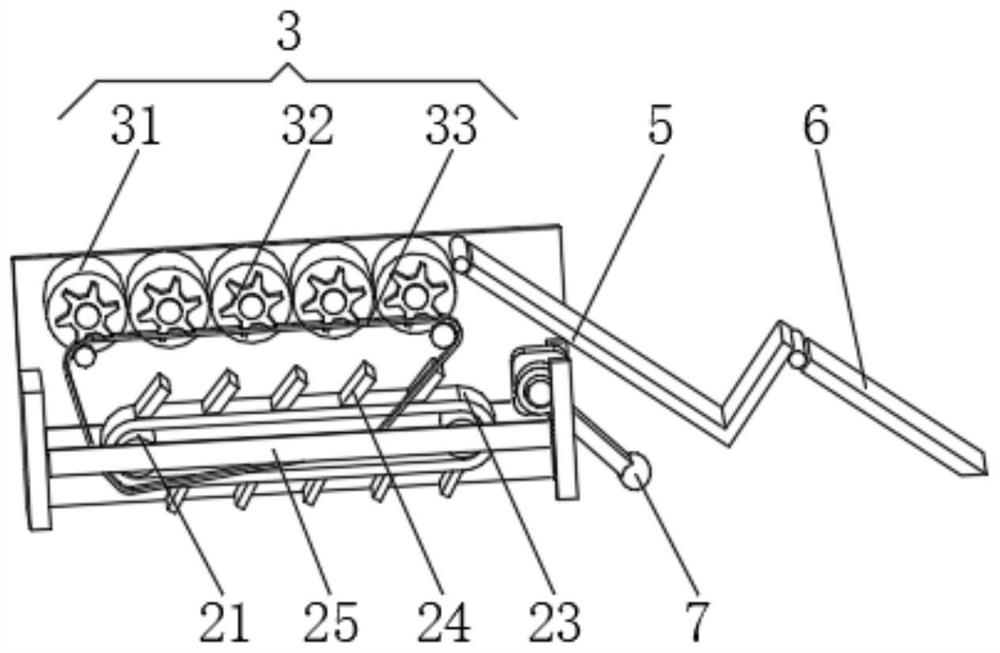

[0034] see Figure 1-3 , the present invention provides a technical solution: a device for automatically placing and positioning electrical automation materials, including

[0035] An installation frame 1, the installation frame 1 has an outer frame 11, and openings at both ends of the outer frame 11;

[0036] Driving device 2, this driving device 2 has driving wheel 21, driven wheel 22, transmission belt 23 and anti-slip tooth 24, anti-slip tooth 24 is arranged on the outside of transmission belt 23, and anti-slip tooth 24 extends away from the end of transmission belt 23 to the outer frame 11 outside;

[0037] Positioning device 3, this positioning device 3 has positioning roller 31, and one end of positioning roller 31 is provided with driven gear 32, and positioning device 3 also has driving chain 33, and the inner wall side of outer frame 11 is provided with guide wheel, and driving chain 33 and The driving wheel 21 is connected.

[0038]When in use, the outer frame 11...

Embodiment 2

[0044] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 1, an anti-leakage cavity is provided on the outside of the positioning roller 31, and an isolation plate 81 is evenly installed inside the anti-leakage cavity, and a spacer is provided between the two sides of the isolation plate 81. Release paper 82, release paper 82 is absorbent paper.

[0045] One end of the isolation plate 81 is provided with an arc-shaped bump 83, and both sides of the arc-shaped bump 83 are provided with an extension cloth 84, and one end of the extension cloth 84 is provided with a sticky block 85, and the extension cloth 84 is close to one end of the arc-shaped bump 83 Scissors 86 are provided.

[0046] An adsorption plate 91 is arranged between the two sides of the isolation plate 81 , and a magnet block 92 is evenly arranged on the outside of the adsorption plate 91 .

[0047] During use, the barrel-shaped material on the electrical automation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com