Wooden plywood and preparation method thereof

A wooden plywood and wood technology, applied in the field of wooden plywood and its preparation, can solve the problems of wood perishable and moth-eaten, natural defects of wood, easy burning of wood, etc., and achieve strong resistance, cost-effective, environment-friendly Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 A kind of wooden plywood and preparation method thereof

[0038] Step 1, after the huanghuali is processed, the remaining scraps are processed and beaten into wood powder of 400-800 mesh;

[0039] Step 2, making a skeleton with bamboo strips;

[0040] Step 3: Mix 500g of wood powder, 100g of rice stalk powder and 0.5g of silicon dioxide to obtain a mixed powder, add 250g of unsaturated resin adhesive to the mixed powder, pour it into the mold, add 120g of bamboo strip skeleton, 15g of fiber, Essence 0.5g, hollow tube 14g, 30 minutes out of the mold, resin glue polishing, that is, the required wooden splint.

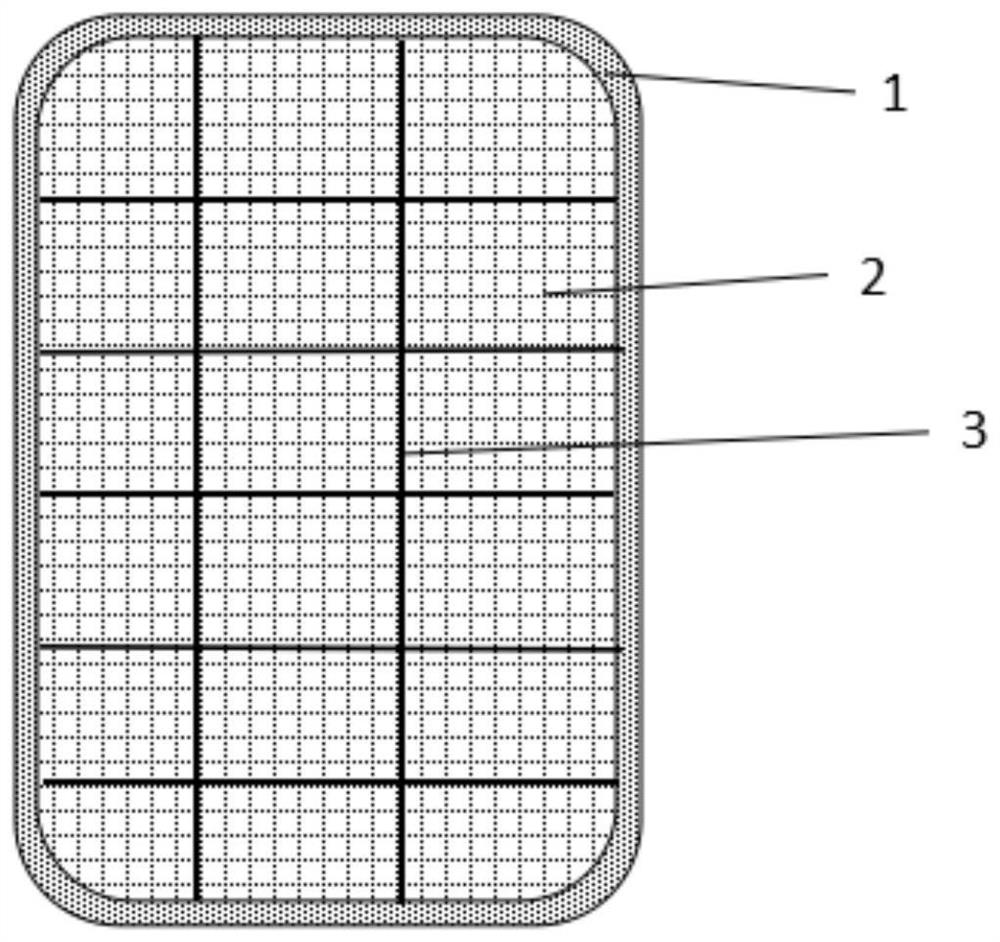

[0041] The method of using the unsaturated resin adhesive is to pour 300g of resin first, then add blue water, which is 9g of accelerator, and then add the white water of oxidant, which is 6g of initiator, after stirring evenly, to obtain the unsaturated resin adhesive; the obtained wood The schematic diagram of the plate is figure 1 As shown, furni...

Embodiment 2

[0042] Embodiment 2 A kind of wooden plywood and preparation method thereof

[0043] Step 1, after the processing of Siamese rosewood, the remaining scraps are processed and beaten into 400-800 mesh wood powder;

[0044] Step 2, making a skeleton with bamboo strips;

[0045] Step 3: Mix 800g of wood powder and 0.5g of silica evenly to obtain mixed powder, add 100g of acrylic glue to the mixed powder, pour it into the mold, add 70g of skeleton, 15g of fiber, 0.5g of essence, 14g of hollow tube, 30 The mold is released in minutes, and the resin glue is polished to obtain the required wooden plywood; furniture made of wooden boards such as image 3 shown.

Embodiment 3

[0046] Embodiment 3 A kind of wooden plywood and preparation method thereof

[0047]Step 1: After the red sandalwood is processed, the remaining fragments are processed and crushed into 400-800 mesh wood powder; the processed fragments of ivory bone or mammoth teeth are crushed into 400-800 mesh to obtain dental bone powder;

[0048] Step two, make the skeleton with bamboo strips;

[0049] Step 3: Mix 500g of wood powder, 200g of dental bone powder and 0.5g of silicon dioxide to obtain a mixed powder, add 200g of unsaturated resin adhesive to the mixed powder, pour it into the mold, add 70g of skeleton, 15g of fiber, and 0.5 g, hollow tube 14g, take out the mold in 30 minutes, polish with resin glue, obtain the required wooden plywood; Figure 4 shown.

[0050] The method of using the unsaturated resin adhesive is to first pour 300g of resin, then add 9g of blue water, that is, an accelerator, stir well, then add white water of an oxidant, that is, 6g of an initiator, and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com