Gob-side entry retaining roadside filling support material using modified industrial gypsum to solidify red mud and preparation method of gob-side entry retaining roadside filling support material

A technology of industrial gypsum and production method, which is applied in the direction of filling, mining equipment, earth cube drilling and mining, etc., can solve the problems of high water filling and high cost, and achieve the effects of prolonging service life, good stability and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A filling and support material for gobside entry retaining and roadside retention with modified industrial gypsum solidified red mud, prepared from the following raw materials in parts by weight: 70-85 parts of red mud, 13-30 parts of modified industrial gypsum 2 to 10 parts of compound additives.

[0032] The above-mentioned red mud is the solid waste discharged from the production of alumina by the Bayer process.

[0033]The modified industrial gypsum used above is obtained by mixing industrial gypsum with fly ash and anthracite, grinding and homogenizing, heating in microwave at 800°C to 1200°C for 30min to 60min, and then grinding to below 200 mesh. Rigid gelling material. The raw material ratio of the modified industrial gypsum is calculated by weight: 65-80 parts of industrial gypsum, 18-34 parts of fly ash, and 2-8 parts of anthracite.

[0034] The composite additive is prepared by mixing the following raw materials in parts by weight: 0-100 parts of silica fum...

Embodiment 2

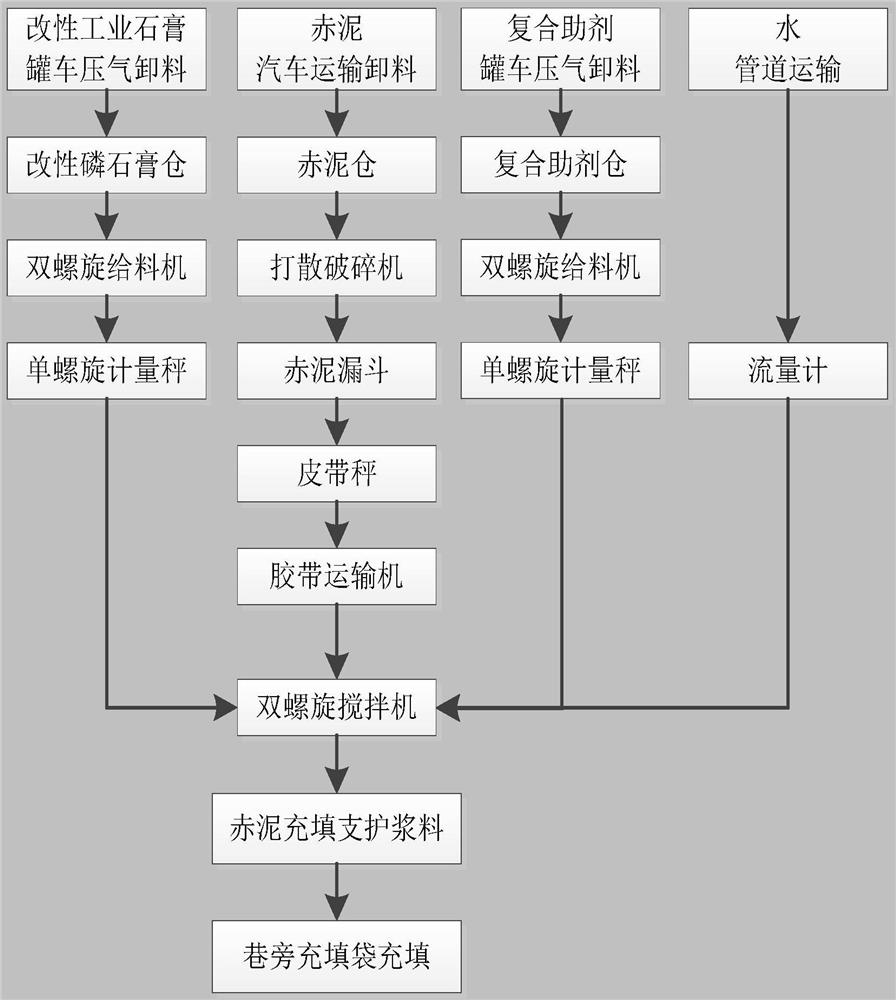

[0043] figure 1 Schematically shows a process flow chart of a method for filling supporting materials by using modified industrial gypsum to solidify red mud for gob-side entry retaining according to the present invention.

[0044] Such as figure 1 As shown, a preparation method of filling and supporting materials for gobside entry retention with modified industrial gypsum solidified red mud includes the following steps:

[0045] First, the red mud waste discharged by the alumina company is transported to the red mud yard for unloading by mine trucks, and then the red mud is transferred to the red mud bin by the loader, and sent to the dispersing crusher by the belt conveyor to be broken up The crushed red mud is transported to the belt scale through the red mud funnel for measurement, and then sent to the twin-shaft mixer by the belt conveyor for premixing;

[0046] Red mud composite additives are transported to the site by tanker, compressed air is unloaded and transported...

Embodiment 3

[0051] The method of Example 1 is used to make the red mud filling and supporting materials beside the gob-side entry retention. The ratios of red mud, composite additives, and modified industrial gypsum entering the twin-shaft mixer are 7.1:1.0:1.9 respectively, and the water-cement ratio is 0.65. After adding regulated water and stirring well, prepare the red mud filling and supporting material slurry beside the gob-side entry retention; the uniaxial compressive strength of the test block 7d is 19.8MPa, and the uniaxial compressive strength of 28d is 18.5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com