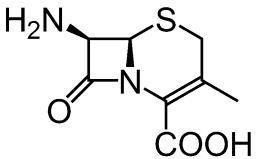

Process for preparing 7-ADCA by taking DAOC fermentation liquor as raw material

A 7-ADCA and fermented liquid technology, applied in fermentation, organic chemistry, etc., can solve the problems of complicated process, low product purity and yield, low purity, etc., and achieve the effect of simple operation process, high conversion rate and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

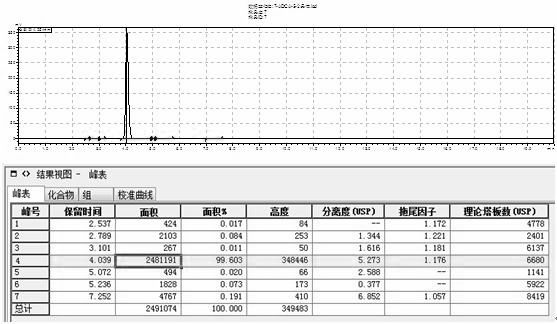

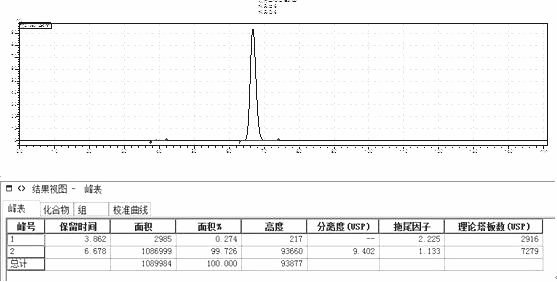

Examples

Embodiment 1

[0054] (1) After the fermentation, take 1.5L of DAOC fermentation broth, add 4mol / L sodium hydroxide solution, adjust the pH of the fermentation broth to 11, and centrifuge at 8000 to remove large insoluble particles, and wash the centrifuged solids with a certain amount of water. Obtain the mixed feed liquid of supernatant liquid and cleaning liquid, adjust feed liquid pH=3.5, place for subsequent use;

[0055] (2) Use macroporous adsorption resin for preliminary extraction of the treatment solution: the resin is DM1180 macroporous adsorption resin produced by Amicogen (China) Biomedical Co., Ltd. (40mL, specific surface is 450㎡ / g, pore diameter is 16nm, ) is the pre-column, DM700 resin (500mL, specific surface is 1360㎡ / g, pore size is 6nm,) is the adsorption column, the upper column liquid is the pretreatment liquid, the upper column volume is 1.3L (25.74g), and the adsorption flow rate is 1.0BV / h, wash 4BV of water, the flow rate is 1BV / h, the adsorption capacity is 51.28m...

Embodiment 2

[0061] (1) After the fermentation, take 1.5L of DAOC fermentation broth, add 4mol / L sodium hydroxide solution, adjust the pH of the fermentation broth to 9.5, and centrifuge at a speed of 10,000 to remove large insoluble particles, and wash the centrifuged solids with a certain amount of water. Obtain the mixed feed liquid of supernatant liquid and cleaning liquid, adjust feed liquid pH=4.0, place for subsequent use;

[0062] (2) Use macroporous adsorption resin for preliminary extraction of the treatment solution: the resin is DM1180 macroporous adsorption resin produced by Amicogen (China) Biomedical Co., Ltd. (45mL, specific surface is 450㎡ / g, pore diameter is 12nm) It is a pre-column, DM700 resin is (520mL, specific surface is 1280㎡ / g, pore size is 8nm), adsorption column, the upper column liquid is pretreatment liquid, the upper column volume is 1.4L (27.72g), and the adsorption flow rate is 1.5BV / h , washed with 6BV of water, the flow rate is 1BV / h, the adsorption capaci...

Embodiment 3

[0068] (1) After the fermentation, take 1.5L of DAOC fermentation broth, add 4mol / L sodium hydroxide solution, adjust the pH of the fermentation broth to 10.8, and centrifuge at 10,000 to remove large insoluble particles, and wash the centrifuged solids with a certain amount of water. Obtain the mixed feed liquid of supernatant liquid and cleaning liquid, adjust feed liquid pH=3.0, place for subsequent use;

[0069] (2) Use macroporous adsorption resin for preliminary extraction of the treatment solution: the resin is DM1180 macroporous adsorption resin (40mL, specific surface: 350㎡ / g, pore diameter: 14nm) produced by Amicogen (China) Biomedical Co., Ltd. Pre-column, DM700 resin is (480mL, specific surface is 1200㎡ / g, pore size is 7nm), adsorption column, the upper column liquid is the pretreatment liquid, the upper column volume is 1.1L (20.92g), the adsorption flow rate is 3BV / h, wash with water 6BV of water, the flow rate is 3BV / h, the adsorption capacity is 39.42mg / mL, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com