Method for evaluating high-temperature gas scouring resistance of titanium-aluminum-based alloy

An evaluation method and alloy-based technology, applied in the direction of strength characteristics, test wear resistance, instruments, etc., can solve the problems of inability to clarify the coupling relationship of various service conditions, complex ground simulation test equipment, high test cost, etc., and achieve low implementation cost , prevent explosion and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

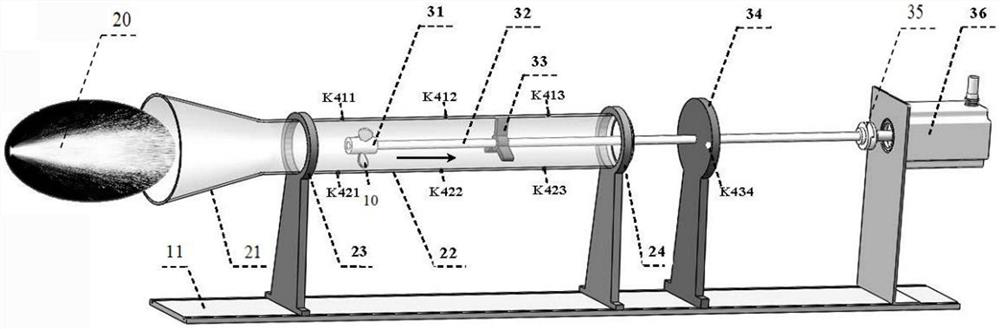

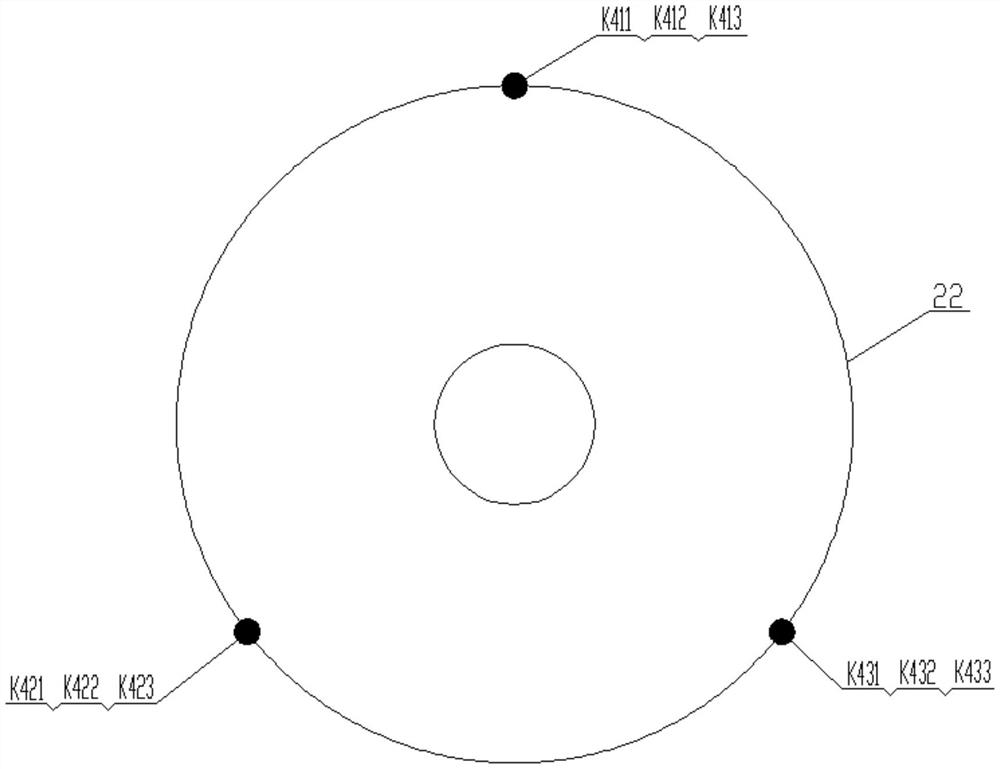

[0026] First, the scouring test device in the present invention is described, see figure 1 , which includes a high-temperature gas generating device for generating stable and continuous high-temperature and high-pressure gas. The high-temperature gas generation device used can continuously inject high-temperature gas with a pressure greater than 0.5MPa and a temperature of 500-1500°C. The high-temperature gas generation device used can be commercial equipment, such as: supersonic oxygen combustion spray gun (HVOF), supersonic air combustion spray gun (HVAF), plasma spray gun. The high-temperature gas generation device can also be equipped with a particle supply device (such as a commercial thermal spray powder feeding device), which is used to supply ceramic particles to the high-temperature and high-pressure gas to simulate the impact of sand and dust.

[0027] When in use, the high-temperature and high-pressure gas 20 produced by the high-temperature gas generating device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com