Water steam cracking catalyst and preparation method thereof as well as water steam cracked hydrogen combustion method

A technology for cracking catalysts and water vapor, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of not being able to use hydrogen energy in water cheaply, and achieve Effects of stable combustion, prevention of explosion accidents, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

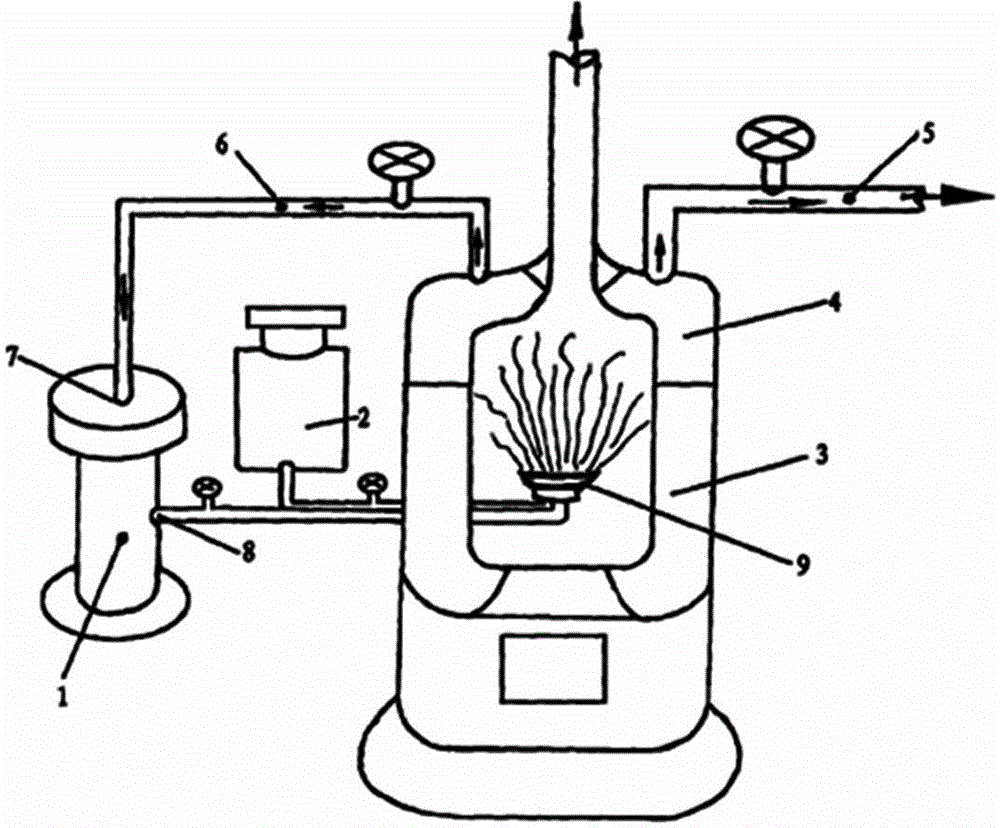

Image

Examples

Embodiment 1

[0033] Separately pulverize elemental iron, elemental aluminum, elemental platinum, sodium chloride, refined molybdenite, and refined manganese ore. Mix 0.3 kg of iron powder, 08 kg of aluminum powder, 0.6 kg of platinum powder, 1.2 kg of sodium chloride powder, 1.2 kg of molybdenite powder and 4.5 kg of manganese ore powder with water glass and place them in a square mold. Compression molded under atmospheric pressure.

Embodiment 2

[0035] Separately pulverize elemental iron, elemental aluminum, elemental platinum, sodium chloride, refined molybdenite, and refined manganese ore. Mix 0.5 kg of iron powder, 3 kg of aluminum powder, 0.1 kg of platinum powder, 0.8 kg of sodium chloride powder, 2.5 kg of molybdenite powder and 0.8 kg of manganese ore powder with water glass and place them in a square mold. Compression molded under atmospheric pressure.

Embodiment 3

[0037]Separately pulverize elemental iron, elemental aluminum, elemental platinum, sodium chloride, refined molybdenite, and refined manganese ore. Mix 1.5 kg of iron powder, 1.3 kg of aluminum powder, 1.5 kg of platinum powder, 0.1 kg of sodium chloride powder, 1 kg of molybdenite powder and 3.5 kg of manganese ore powder with water glass and place them in a square mold. Compression molded under atmospheric pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com