Intelligent prediction method and system for residual life of main speed reducer, equipment and medium

A technology of intelligent prediction and main reducer, which is applied in the direction of neural learning methods, instruments, biological neural network models, etc., can solve problems such as instability, feature loss, and low prediction accuracy, so as to solve discontinuity problems and avoid Overfitting phenomenon, to achieve the effect of health management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figure 1-9 The application is described in further detail.

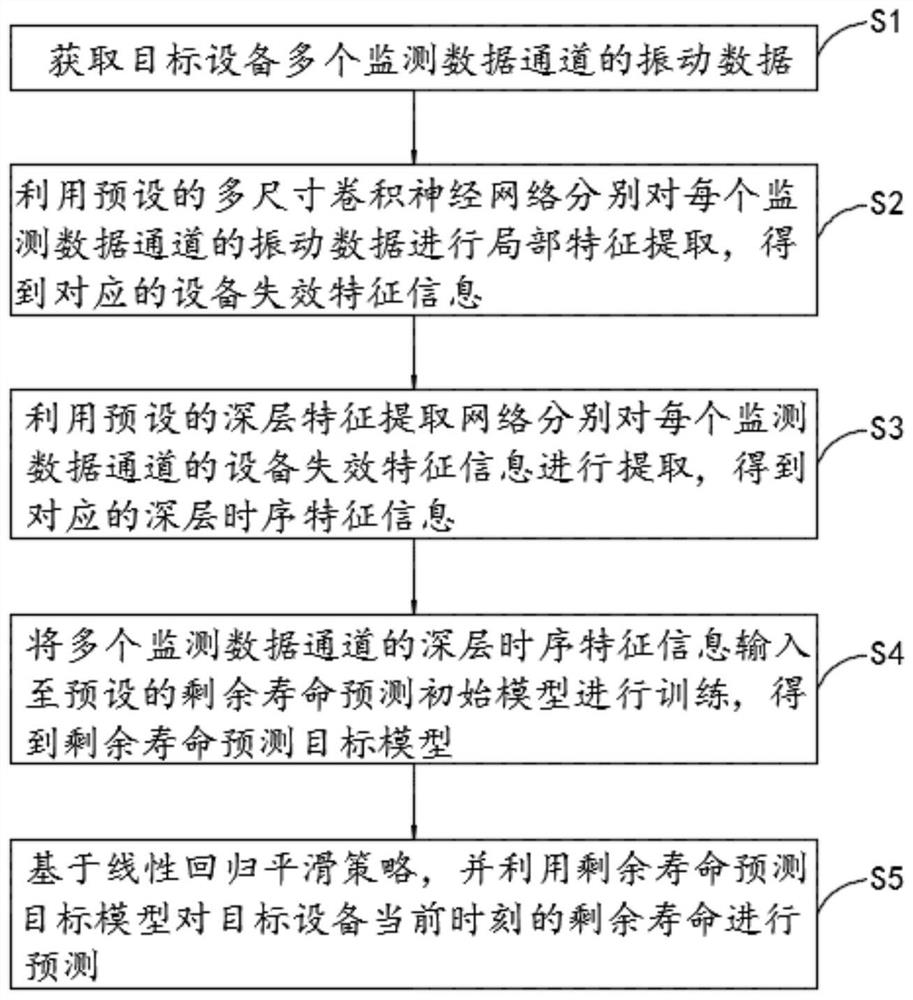

[0047] The embodiment of the present application discloses an intelligent prediction method for the remaining life of the final drive, referring to figure 1 , the method includes the following steps:

[0048] S1: Obtain the vibration data of multiple monitoring data channels of the target device;

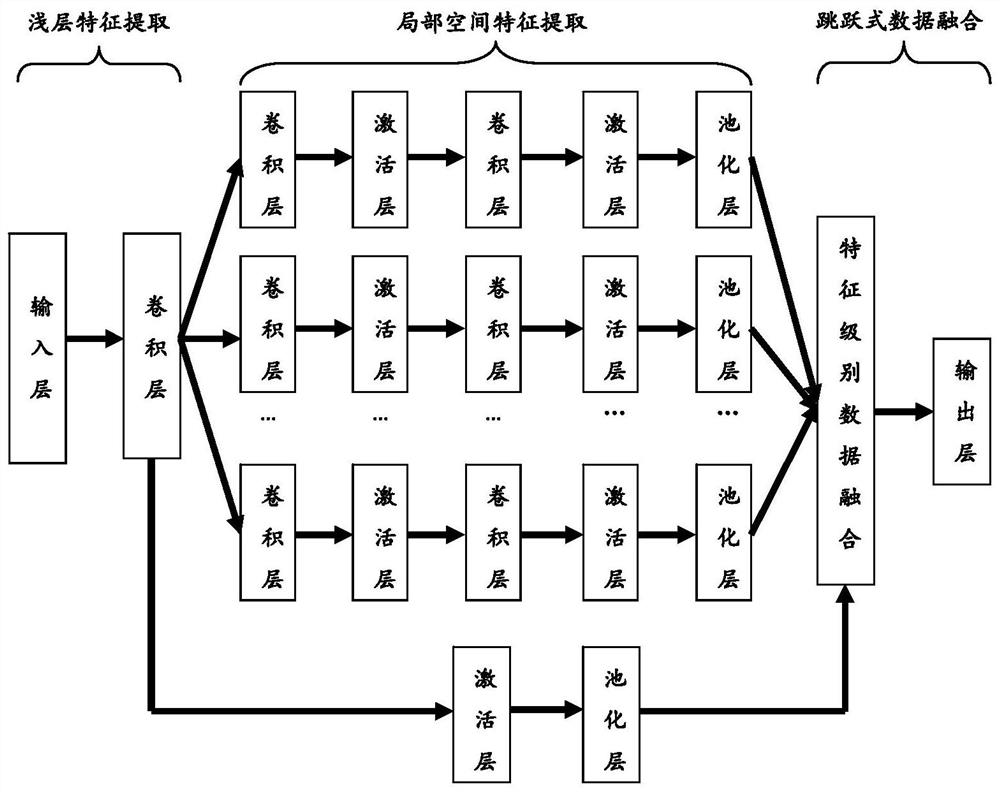

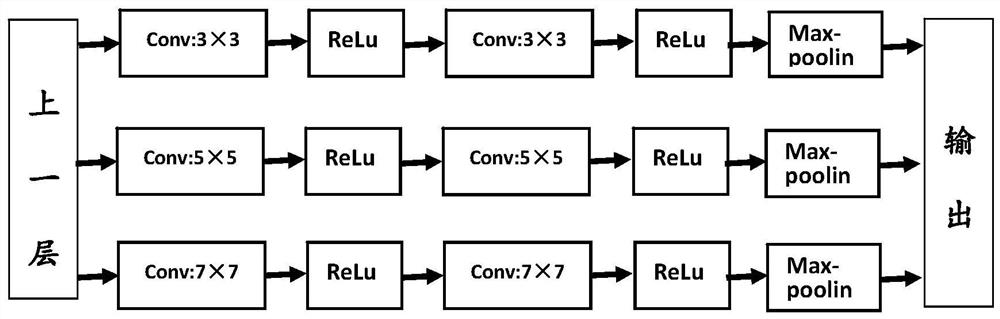

[0049] S2: Use the preset multi-size convolutional neural network to extract local features of the vibration data of each monitoring data channel to obtain the corresponding equipment failure feature information;

[0050] S3: Use the preset deep feature extraction network to extract the equipment failure feature information of each monitoring data channel to obtain the corresponding deep time series feature information;

[0051] S4: Input the deep time series feature information of multiple monitoring data channels into the preset initial model of remaining life prediction for training,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com