Method for forming semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device formation, can solve problems such as semiconductor device performance needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] As mentioned in the background art, existing semiconductor structures have the problem of poor performance.

[0040] A method of forming a semiconductor device, comprising:

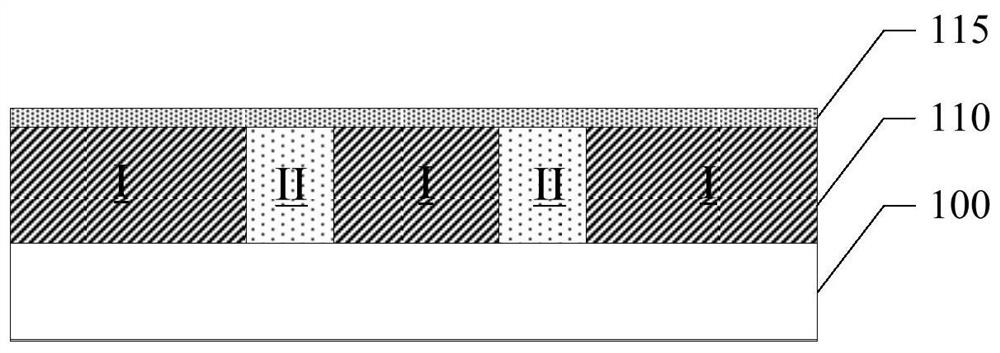

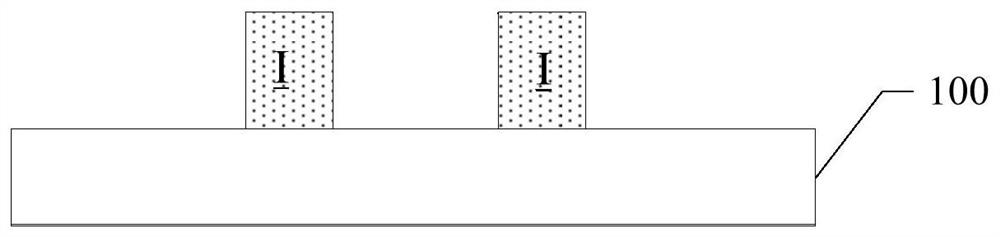

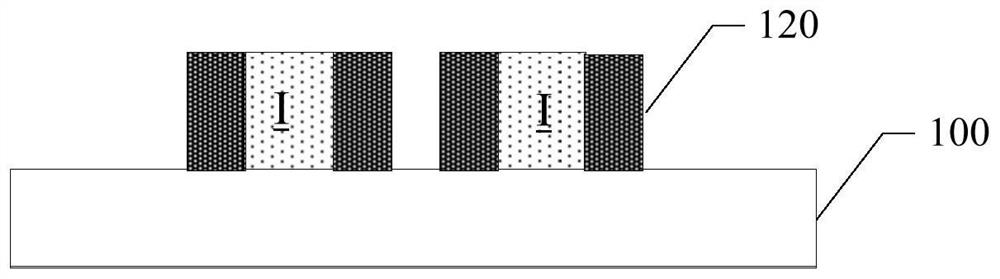

[0041] see figure 1 , providing a substrate (not shown), on which a layer to be etched 100 and a spacer material layer 110 located on the layer to be etched 100 are formed; a spacer doped region I is formed in part of the spacer material layer 110 , the spacer material layer 110 at the side of the spacer doped region I is the spacer of the non-doped region II.

[0042] The process of forming the spacer doped region I includes: a patterned mask layer on the spacer material layer 110, the patterned mask layer has a mask opening; the spacer material layer at the bottom of the mask opening 110 Perform ion implantation to form the interval doped region I; after that, remove the patterned mask layer.

[0043] An ashing process is used in the process of removing the patterned mask layer, and the ashin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com