Preparation method of mixture of hydrogen peroxide and peracetic acid

A hydrogen peroxide-peracetic acid mixture and hydrogen peroxide technology are applied in the field of preparation of disinfectant, and achieve the effects of low corrosiveness, stable performance and high disinfection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

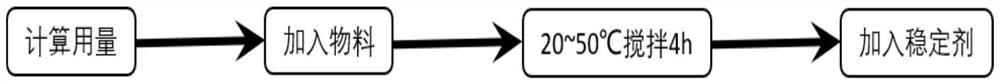

[0021] see figure 1 , the present invention provides a kind of technical scheme: a kind of preparation method of hydrogen peroxide peracetic acid mixture, comprises the raw material of following weight part:

[0022] Hydrogen peroxide: 0-500 parts;

[0023] Acylating agent: 0-400 parts;

[0024] Acid catalyst: 0-10 parts;

[0025] Purified water: 0-900 parts;

[0026] Stabilizer: 0-20 parts.

[0027] The preparation steps are as follows:

[0028] Step 1: Measure 0 to 500 parts of hydrogen peroxide and place it in an enamel reaction tank;

[0029] Step 2: sequentially add 0-400 parts of acylating agent, 0-10 parts of acid catalyst, and 0-900 parts of purified water;

[0030] Step 3: stirring at 20-50°C for more than 4 hours;

[0031] Step 4: After the reaction is complete, add 0-20 parts of stabilizer.

[0032] It is characterized in that the acylating agent is acetic acid.

[0033] The acid catalyst is sulfuric acid.

[0034] The reaction temperature is between 20° C...

Embodiment 1

[0036] Prepare 100kg of high-efficiency disinfectant concentrate containing about 22% hydrogen peroxide and 4.5% peracetic acid:

[0037] Measure about 24kg of hydrogen peroxide, put it in an enamel reaction tank, add about 3.55kg of acetic acid, about 0.5kg of sulfuric acid, about 70.7kg of purified water, and stir at 20-50°C for more than 4 hours. After the reaction is complete, add About 0.15kg stabilizer.

[0038] The 1:20 dilution of the high-efficiency disinfectant concentrate can disinfect the surface of objects, and can also be diluted by an appropriate multiple for dry fog disinfection.

Embodiment 2

[0040] Prepare 100kg of high-efficiency disinfectant concentrate containing about 7% hydrogen peroxide and 1% peracetic acid:

[0041] Measure about 7.45kg of hydrogen peroxide, put it in an enamel reaction tank, add about 0.79kg of acetic acid, about 0.2kg of sulfuric acid, and about 91kg of purified water in sequence, and stir at 20-50°C for more than 4 hours. After the reaction is complete, add About 0.07kg stabilizer.

[0042] The high-efficiency disinfectant can be directly subjected to dry fog disinfection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com