Polishing magnetorheological fluid recovery device based on capillary action

A recovery device and magnetorheological fluid technology, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of low recovery efficiency, reduced recovery processing efficiency, secondary damage of new substances, etc., and achieve high recovery rate , wide range, fast separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

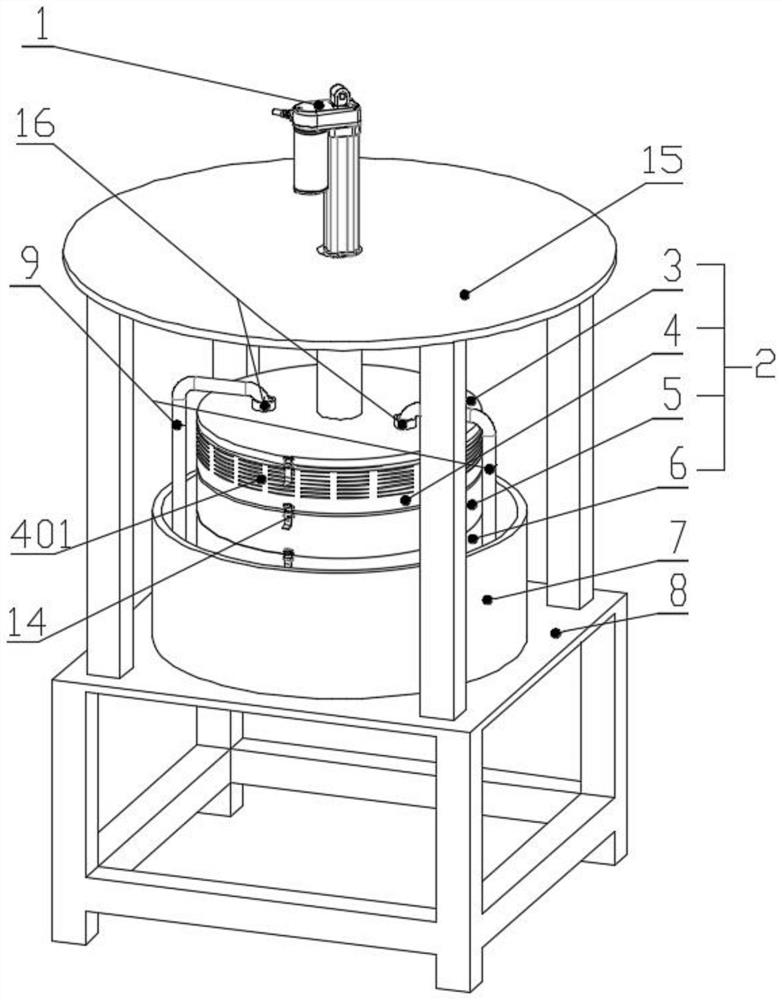

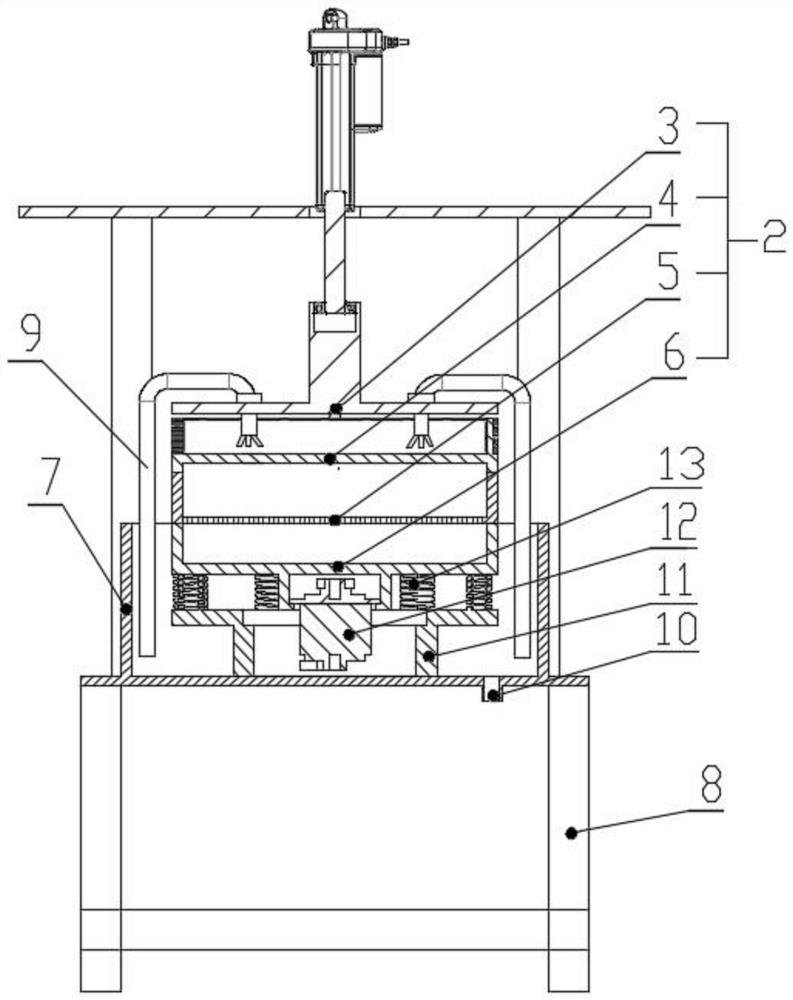

[0046] Embodiment 1: as Figure 1-2 As shown, an embodiment of a recovery device for polishing magnetorheological fluid based on capillary action disclosed by the present invention includes:

[0047] Electric lifting rod 1, upper bracket 15, recovery device 2, support frame 11 and outer bracket 8;

[0048] The electric lifting rod 1 includes a motor end and a lifting end, the motor end is fixedly connected to the middle position of the upper end of the upper support 15, the recovery device 2 is located between the upper support 15 and the outer support 8, The lifting end is connected to the recovery device 2, the recovery device 2 is installed on the support frame 11, and the support frame 11 is installed on the outer support 8;

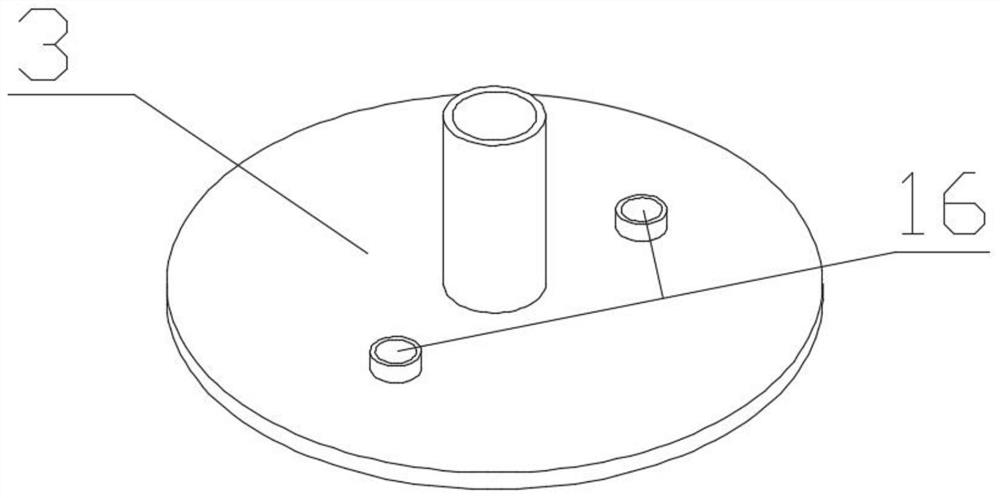

[0049] The recovery device 2 includes an upper end cover 3 arranged from top to bottom, a water and air filter tray 4, a sieve tray 5 and a chassis 6, and the lifting end is fixedly connected to the upper end of the upper end cover 3 and can drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com