Laser machining positioning mechanism for special-shaped metal tubes

A special-shaped metal and laser processing technology, applied in metal processing, metal processing equipment, laser welding equipment, etc., can solve the problems of increased labor costs, high costs, and easy measurement errors, etc., to achieve accurate positioning, reduce labor costs, and reduce processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The embodiment of the present invention provides a special-shaped metal tube laser processing positioning mechanism, which is specially used for clamping and positioning special-shaped metal tubes during laser processing. By taking the special-shaped part of the pipe as a reference, the pipe is installed in place, positioned, and clamped. , and then laser processing. Through the mechanism, the laser processing procedure can be reduced, the laser processing man-hour can be shortened, automatic production can be realized, the yield rate of product processing can be improved at the same time, and the product processing cost can be reduced.

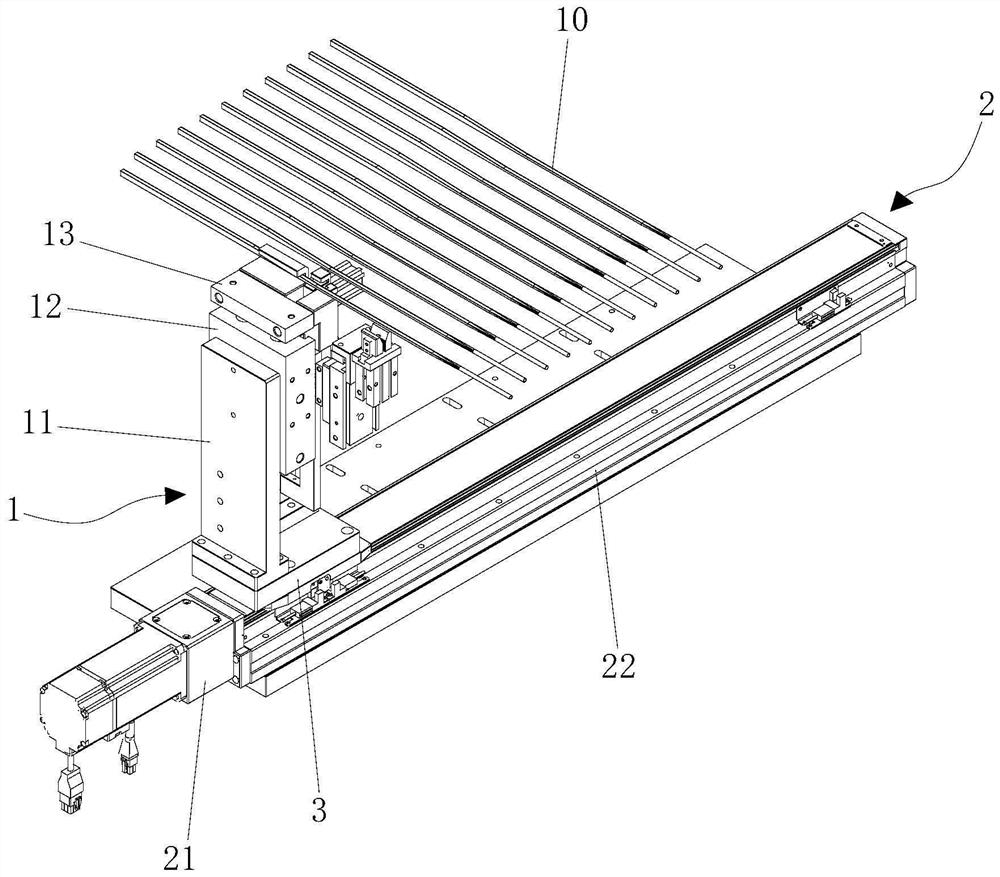

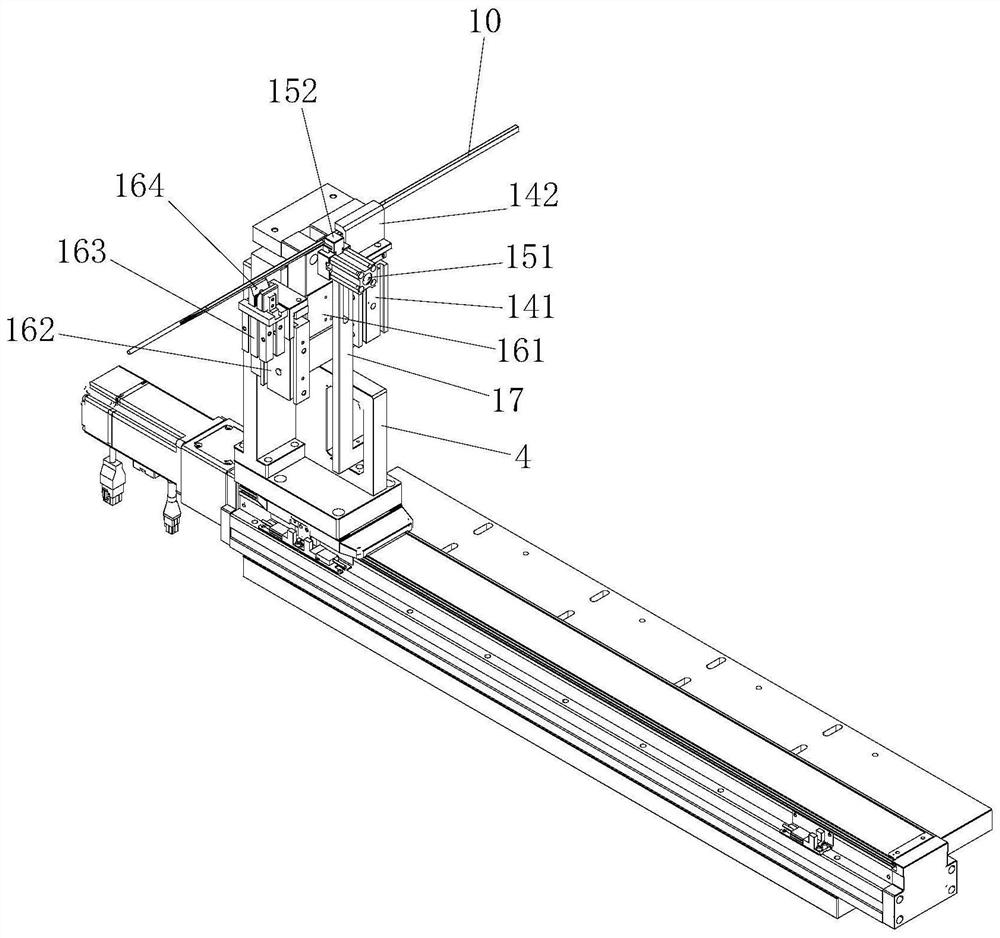

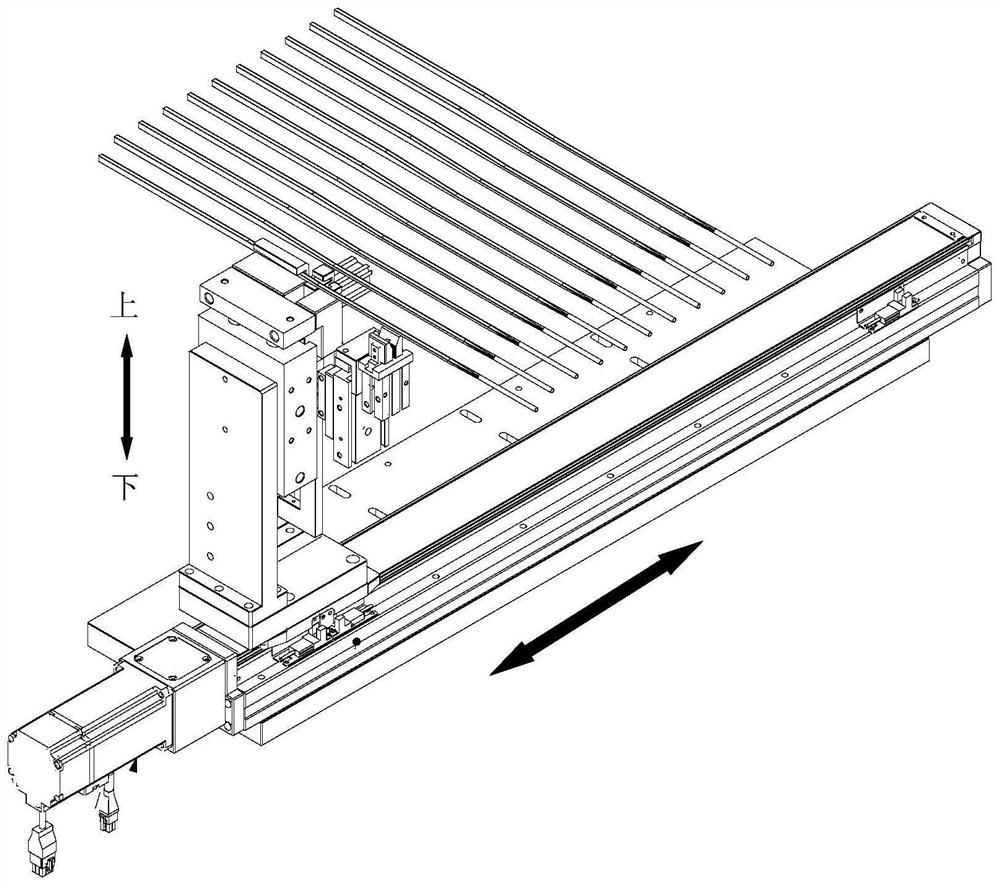

[0031] see figure 1 , figure 2 , the mechanism mainly includes a positioning component 1 and a moving component 2. The positioning component 1 is movably arranged on the moving component 2. The moving component 2 can drive the positioning component 1 to move. The positioning component 1 completes the positioning and clamping of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com