Bottle cap gasket adding machine

A bottle cap and pad machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of not being able to add pads to bottle caps of different sizes, so as to improve processing efficiency, solve picking difficulties, and reduce interval time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

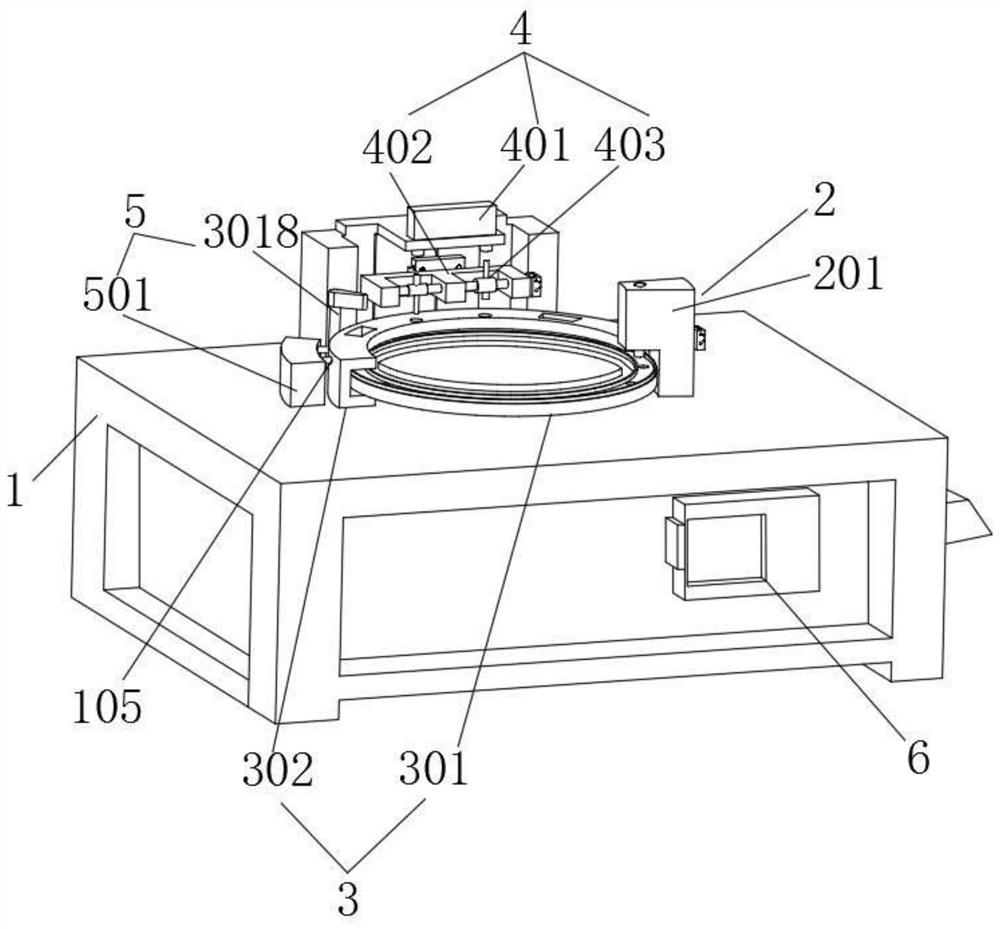

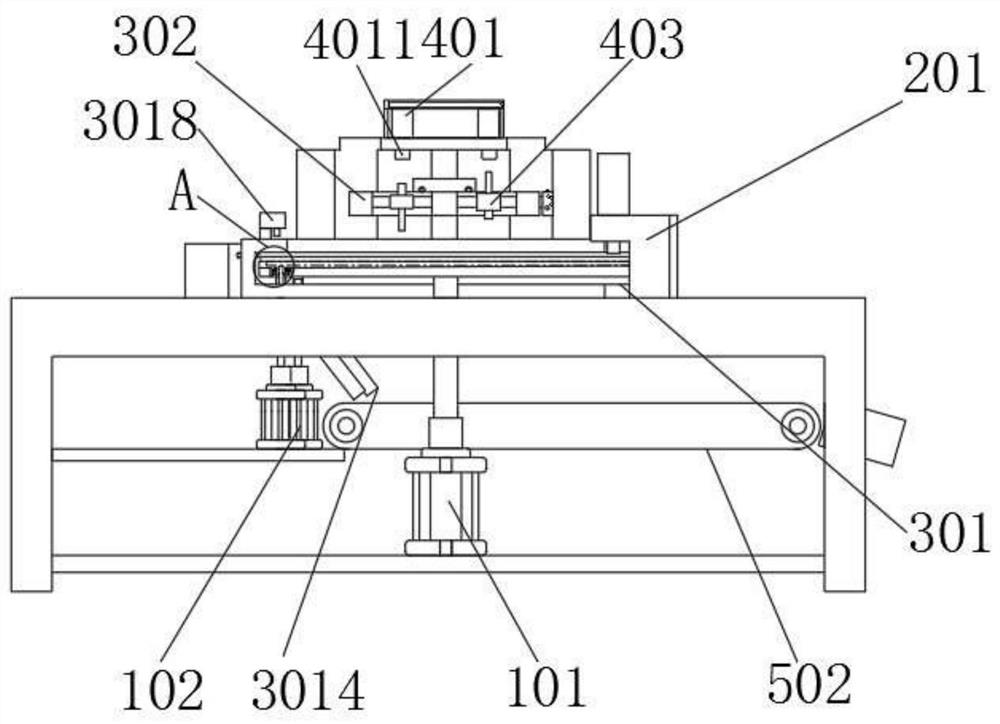

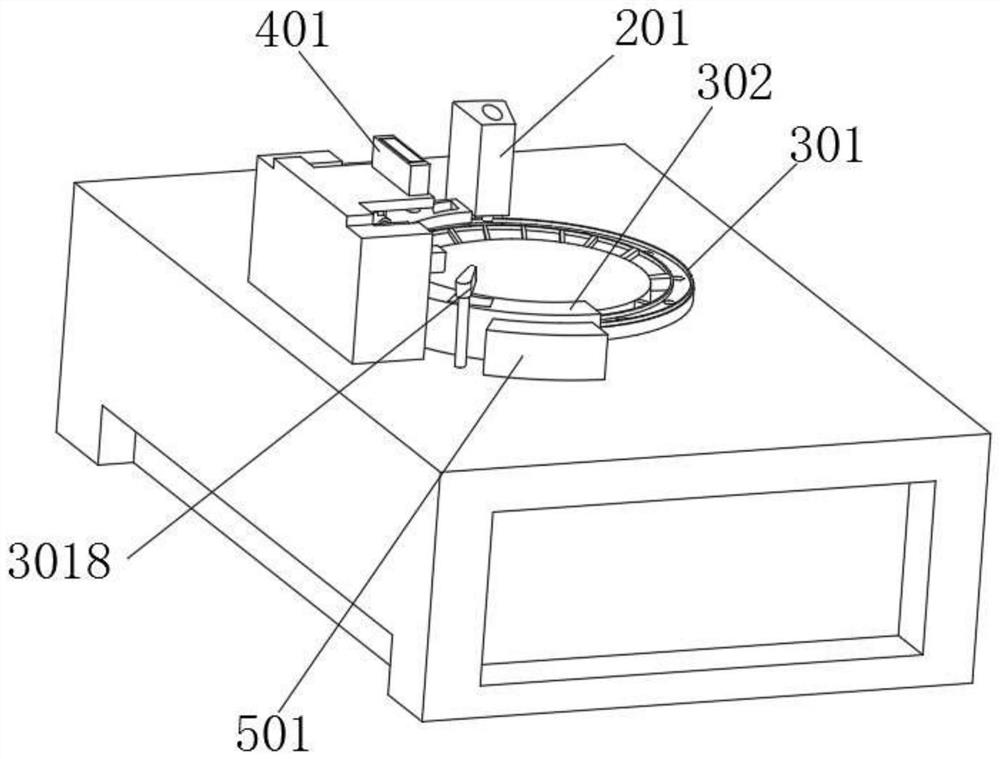

[0041]Embodiment: a bottle cap padding machine, the bottle cap padding machine consists of a workbench 1, an adding part 2 for adding bottle caps, a transmission part 3 for driving the bottle caps, and a processing part 4 for adding pads to the bottle caps It is composed of the blanking part 5 that sends out the bottle cap, the adding part 2 is installed on the upper end surface of the workbench 1, the transmission part 3 is installed in the middle of the upper end surface of the workbench 1, and the processing part 4 is installed on one side of the upper end surface of the workbench 1 , the blanking part 5 is installed on the side of the transmission part 3, the motor and the cylinder appearing in this case are connected with the relay and the AC contactor through the cable and the internal controller of the device, and the signal receiving ends of the motor and the cylinder are connected with the control The controller used in this case is a PLC controller, and a control pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com