Automatic pouring device for aerated concrete blocks

An air-entrained concrete and automatic pouring technology, which is applied to supply devices, ceramic molding machines, manufacturing tools, etc., can solve the problem of not being able to handle voids well, and achieve the effects of reasonable structure, large voids, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

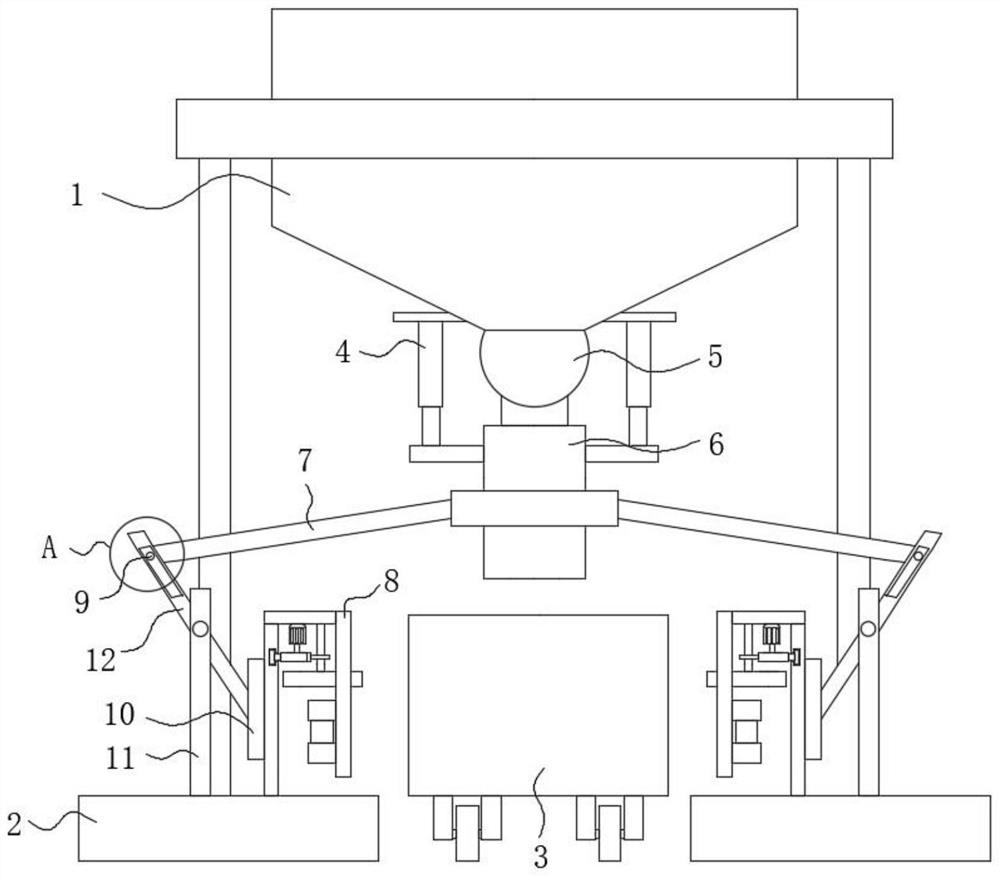

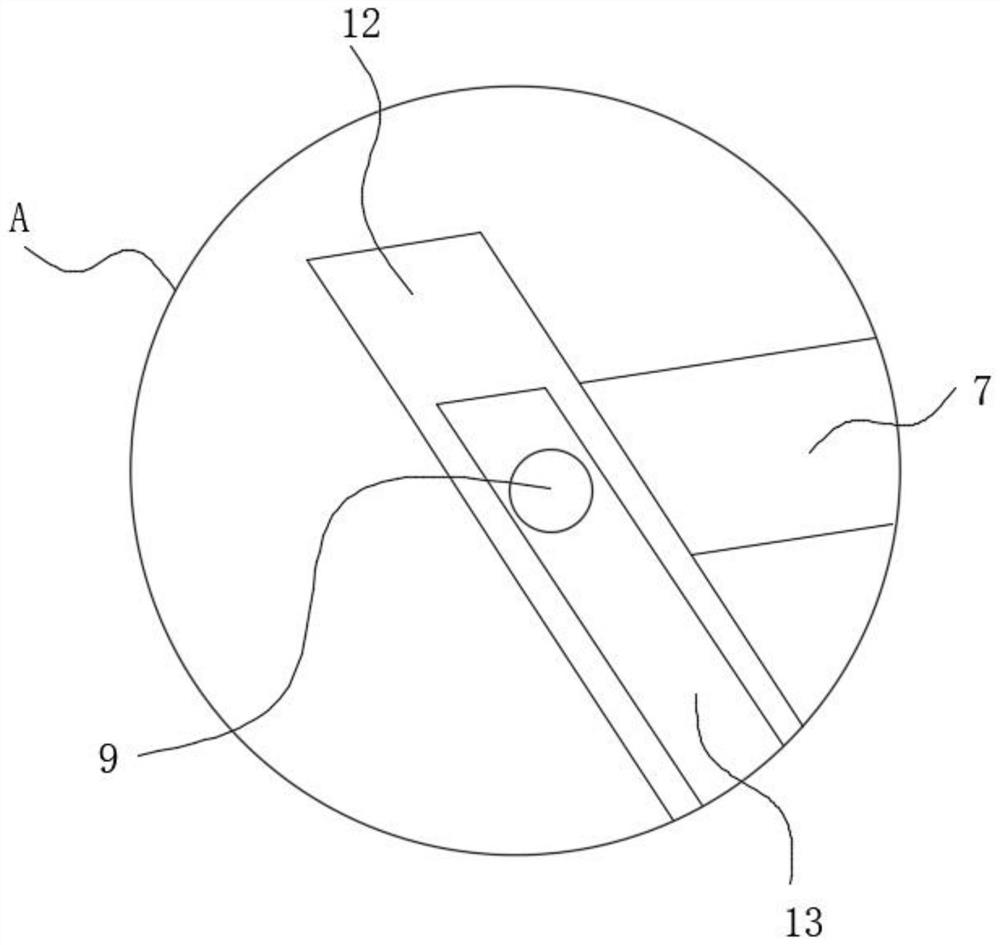

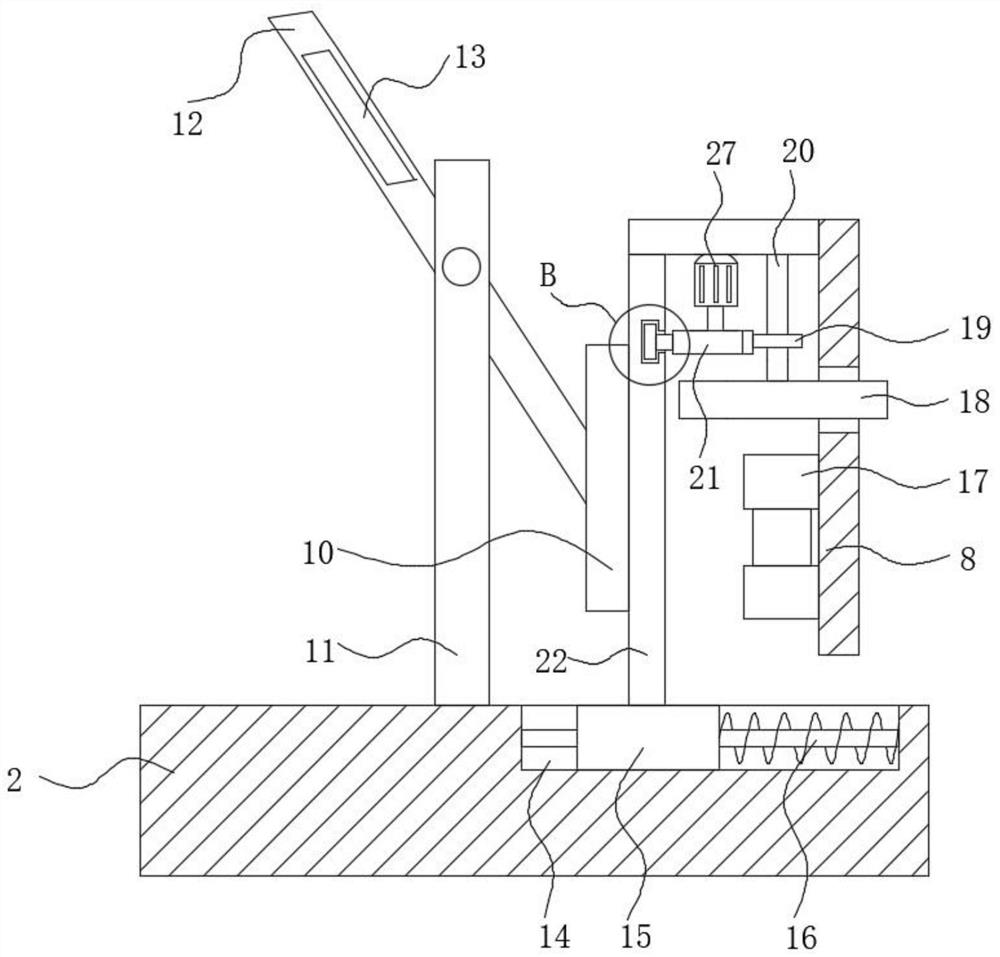

[0032] refer to Figure 1-6 , an automatic pouring device for aerated concrete blocks, comprising:

[0033] The pouring device includes a storage tank 1 and a discharge pipe 6 installed at the bottom of the storage tank 1. A telescopic mechanism is installed between the discharge pipe 6 and the storage tank 1 to drive the discharge pipe 6 up and down. The pouring device also includes a discharge pump 5 installed at the bottom of the storage tank 1. The discharge port of the discharge pump 5 is fixed with a connecting pipe, and the discharge pipe 6 is movably sleeved outside the connection pipe. 1. The two electric telescopic rods 4 on the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com