Feeding, spraying and dust removal device and use method thereof

A technology of dust removal device and nozzle, which is applied to cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., which can solve the problem that it is inconvenient for operators to accurately control the amount of powder added, endangering the health of operators, and increasing Problems such as powder loss, to achieve the effect of protecting health, reducing impact, and reducing powder loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

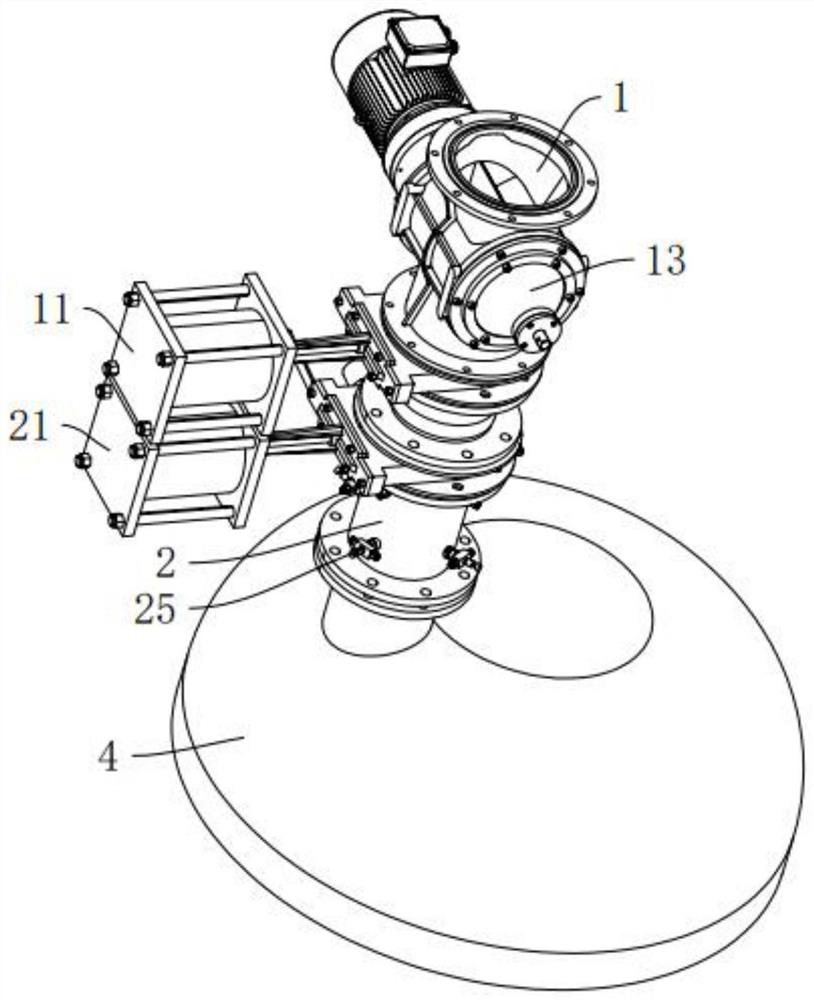

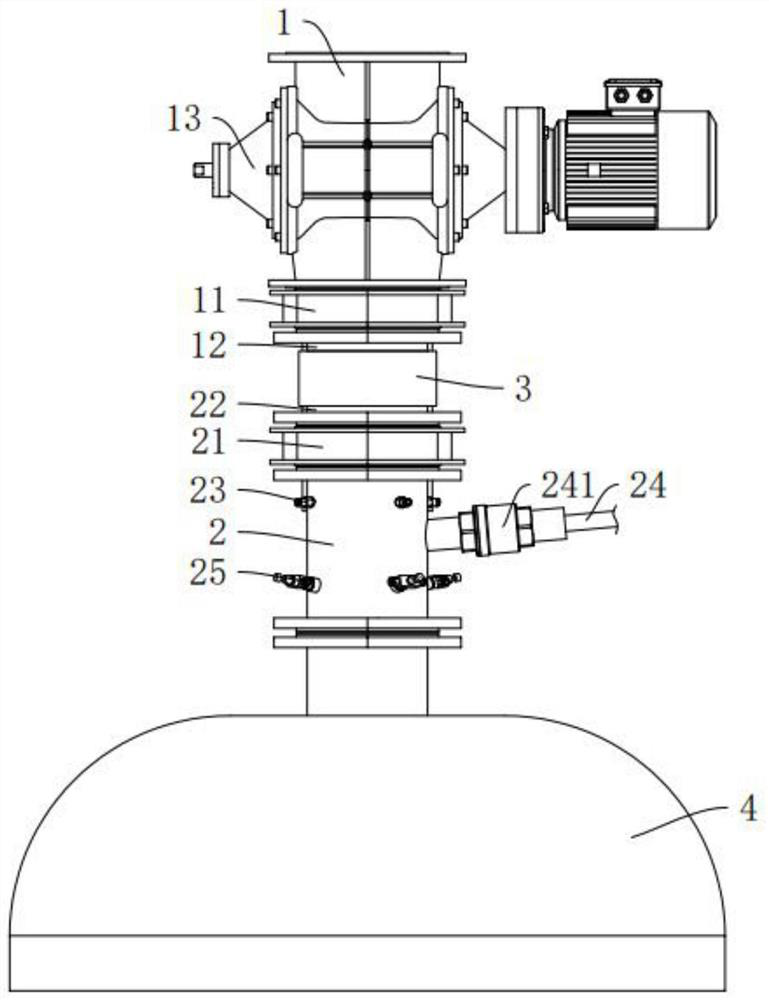

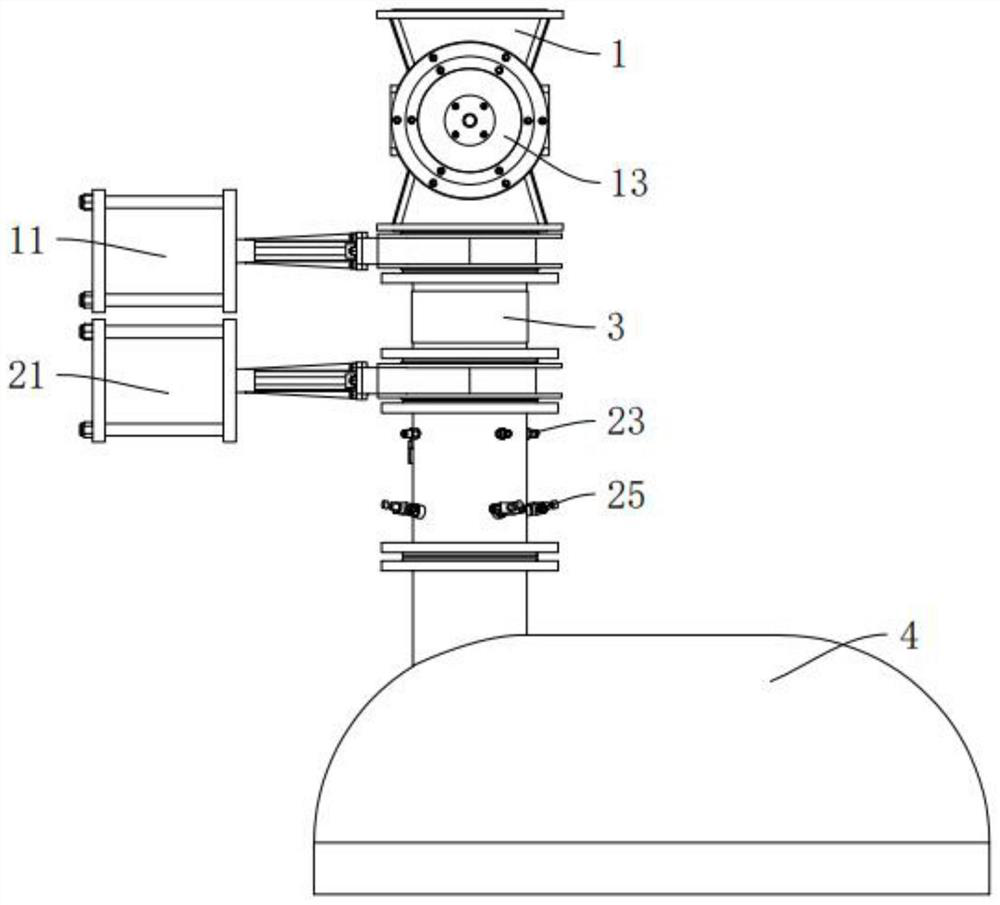

[0035] Please refer to figure 1 , the present application provides a feeding spray dedusting device, which includes a conveying pipeline for conveying powder, and the conveying pipeline is arranged along a vertical direction. One end of the conveying pipeline communicates with the reactor 4 (only the kettle cover of the reactor 4 is shown in the figure), and the other end communicates with the hopper (not shown in the figure). Four first nozzles 25 are installed on the side of the delivery pipeline, and the four first nozzles 25 are evenly arranged around the circumference of the delivery pipeline. The first nozzles 25 are used to spray water mist into the delivery pipeline.

[0036] The water mist ejected from the first nozzle 25 can wet the powder and accelerate the falling of the powder. When the dust is raised, the water mist wets the dust and promotes the raised dust to fall to the reaction kettle 4, thereby reducing the loss of powder in the feeding process and facilita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com