Annealing method of 3Cr17NiMo electroslag ingot

An electroslag ingot and annealing technology, applied in the metallurgical field, can solve the problems of easy explosion, large temperature difference of electroslag ingot, explosion of electroslag ingot, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] In the present invention, the preparation method of the 3Cr17NiMo electroslag ingot preferably includes:

[0066] The alloy raw materials are sequentially subjected to electric furnace melting, LF melting and VD melting to obtain molten steel;

[0067] pouring the molten steel to obtain an electrode base material;

[0068] The electrode base material is subjected to electroslag remelting to obtain a 3Cr17NiMo electroslag ingot.

[0069] The present invention has no special restrictions on the original composition and source of the alloy, and those skilled in the art can carry out batching according to the pre-obtained 3Cr17NiMo electroslag ingot composition, and the alloy raw material can be made of 3Cr17NiMo electroslag ingot steel grade or similar steel grade The return material can be the simple substance of the required alloying elements or the alloy containing the required elements.

[0070] In the present invention, the electric furnace smelting process preferab...

Embodiment 1

[0109] The alloy raw materials are sequentially subjected to electric furnace melting, LF melting and VD melting to obtain molten steel;

[0110] pouring the molten steel to obtain an electrode base material;

[0111] Electroslag remelting is performed on the electrode base material to obtain a φ730mm 3Cr17NiMo electroslag ingot;

[0112] The composition of the 3Cr17NiMo electroslag ingot is: (unit: wt%)

[0113] C mn Si P S Cr Mo Ni Cu Al Fe 0.37 0.62 0.47 0.021 0.002 16.90 1.02 0.65 0.06 0.055 margin

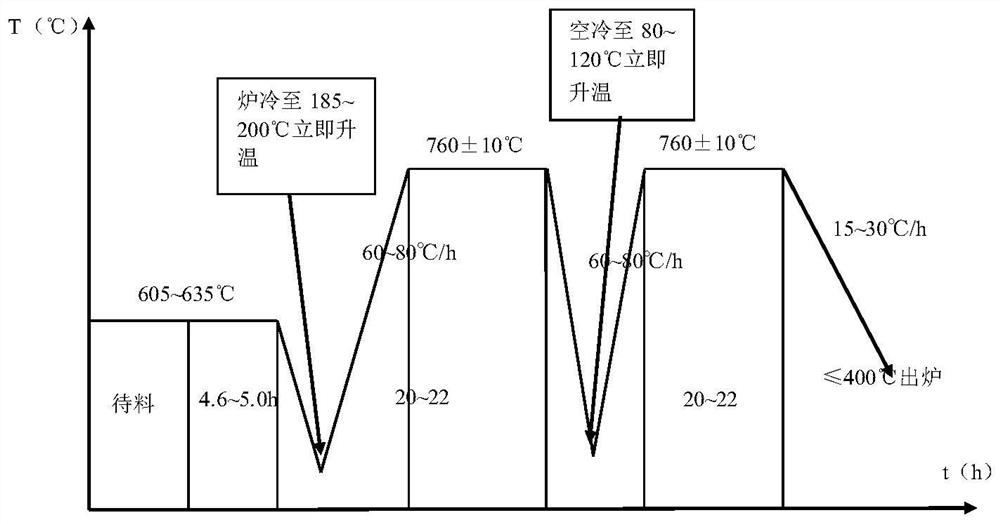

[0114] The 3Cr17NiMo electroslag ingot furnace is cooled for 67min, and the time from demoulding to loading into the annealing furnace is 12min, and the annealing process is carried out as follows: figure 2 Shown:

[0115] Heat the demoulded product at 620°C for 4.7 hours;

[0116] Then the furnace was cooled to 193°C and immediately heated to 760°C for 21 hours, and the heating rate was 70°C / h;

[0117] Then air-cooled to 100°C ...

Embodiment 2

[0121] Alloy raw materials are smelted in electric furnace, LF smelt and VD smelt in sequence, and the steel is melted;

[0122] pouring the molten steel to obtain an electrode base material;

[0123] Electroslag remelting is performed on the electrode base material to obtain a φ730mm 3Cr17NiMo electroslag ingot;

[0124] The composition of the 3Cr17NiMo electroslag ingot is: (unit: wt%)

[0125] C mn Si P S Cr Mo Ni Cu Al Fe 0.39 0.70 0.49 0.0190 0.0019 16.84 1.09 0.71 0.13 0.026 margin

[0126] The 3Cr17NiMo electroslag ingot furnace is cooled for 66 minutes, and the time from demoulding to loading into the annealing furnace is 10 minutes, and the annealing process is performed as follows: image 3 Shown:

[0127] Heat the demoulded product at 623°C for 4.9 hours;

[0128] Then the furnace is cooled to 190°C and immediately heated to 765°C for 21.5 hours, with a heating rate of 80°C / h;

[0129] Then air-cooled to 105°C and imm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com