A drying device for biochemical powder materials

A powder material and biochemical technology, which is applied in the field of drying devices for biochemical powder materials, can solve the problems of easy agglomeration of powder materials, long time required, affecting drying and dehydration efficiency and effect of biochemical powder materials, and the like. Achieve the effect of improving the heating effect, avoiding agglomeration and improving the drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

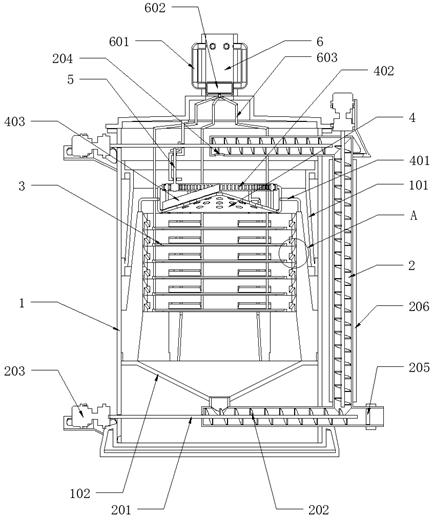

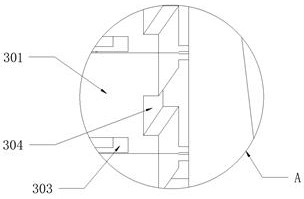

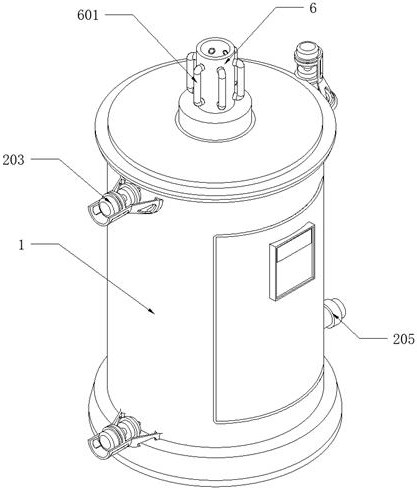

[0044] see figure 1 , Figure 4-5 and Figure 10 , a drying device for powder materials used in biochemical industry, comprising a drying box 1, an electric heating plate 101 is fixedly installed on the inner wall of the drying box 1, and a material storage tray 102 is fixedly installed under the inside of the drying box 1, The interior of the drying box 1 is laid with three conveying pipes 2 vertically connected to each other. The conveying pipe 2 located below is fixedly connected with the bottom of the storage tray 102. Insulation layer 206, when the device works, the powder materials stored on the storage tray 102 are transported upwards through three interconnected delivery pipes 2, so as to realize the up and down replacement operation of powder materials during drying. Wrapped on the conveying pipe 2 exposed on the outside, it can effectively weaken the heat dissipation of the powder material inside the conveying pipe 2. The insulation layer 206 can be heat-insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com