Low-temperature evaporation emulsified asphalt residue softening point tool, preparation method and testing method

A technology of emulsified asphalt and low-temperature evaporation, which is applied in the investigation stage/state change and other directions, can solve the problems such as the inability to truly reflect the performance of emulsified asphalt, and achieve the effect of avoiding uneven levels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a preparation method for the softening point of low-temperature evaporating emulsified asphalt residue, based on the above-mentioned low-temperature evaporating emulsified asphalt residue softening point tooling, comprising the following steps:

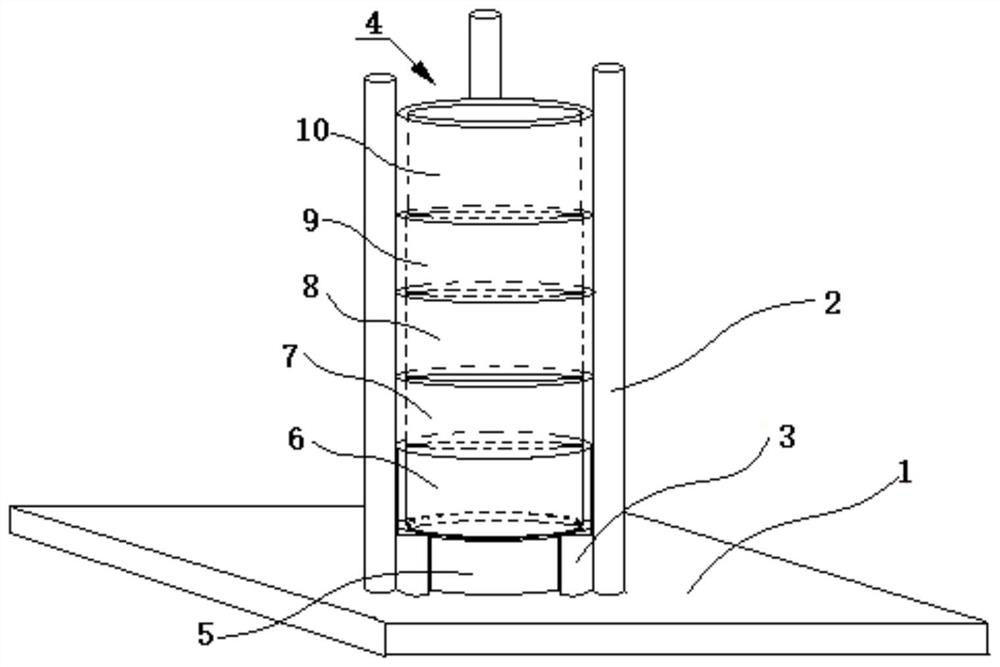

[0045] Place the first softening point ring 5, the second softening point ring 6, the third softening point ring 7, the fourth softening point ring 8, the fifth softening point ring 9 and the sixth softening point ring 10 on the silica gel plate, wherein, The height of the first softening point ring 5 is 3.2mm, the inner diameter is 15.9mm, and the outer diameter is 19mm; the second softening point ring 6, the third softening point ring 7, the fourth softening point ring 8, and the fifth softening point ring 9 The inner and outer diameters and heights of the sixth softening point ring 10 are the same, the inner diameter is 19.8mm, the outer diameter is 23mm, and the height is 3.2mm; the size o...

Embodiment 1

[0056] Place a silicone plate with a thickness of 5mm and a length and width of 10cm in an iron plate with a flat bottom, and place the first softening point ring 5, the second softening point ring 6, the third softening point ring 7, and the fourth softening point ring 8. The fifth softening point ring 9 and the sixth softening point ring 10 are evenly placed on the silica gel plate;

[0057] Use a clean beaker to prepare 500g of emulsified asphalt sample, and let it stand for 30 minutes to ensure that there are no air bubbles in the emulsified asphalt, inject the emulsified asphalt into each softening point ring, and ensure that the emulsified asphalt is just filled and cannot overflow;

[0058] Place the iron plate and silica gel plate together with the ring filled with the emulsified asphalt sample at room temperature for 24 hours

[0059] Then put the iron plate and the silica gel plate in the iron plate together with the softening point ring that has been injected with t...

Embodiment 2

[0073] Place a silicone plate with a thickness of 5mm and a length and width of 10cm in an iron plate with a flat bottom, and place the first softening point ring 5, the second softening point ring 6, the third softening point ring 7, and the fourth softening point ring 8. The fifth softening point ring 9 and the sixth softening point ring 10 are evenly placed on the silica gel plate;

[0074] Prepare 500g of emulsified asphalt sample in a clean beaker, and let it stand for 5 minutes to ensure that there are no air bubbles in the emulsified asphalt, inject the emulsified asphalt into each softening point ring, and ensure that the emulsified asphalt is just filled and cannot overflow;

[0075] Place the iron plate, silica gel plate and the ring filled with the emulsified asphalt sample at room temperature for 25 hours;

[0076] Then put the iron plate and the silica gel plate in the iron plate together with the ring that has been injected with the sample into the oven that has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com