Fan blade surface crack monitoring device and method and induction material coating method

A technology for surface cracks and fan blades, applied in the field of blades, can solve the problems of ineffective monitoring, difficult maintenance, large crack size, etc., to achieve the effect of effective monitoring and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

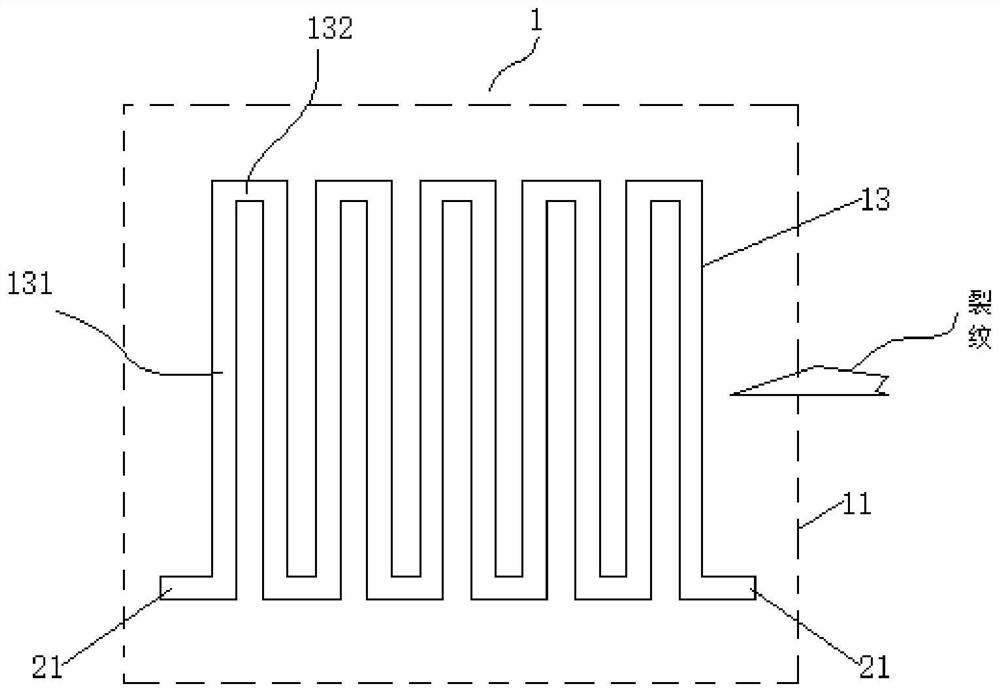

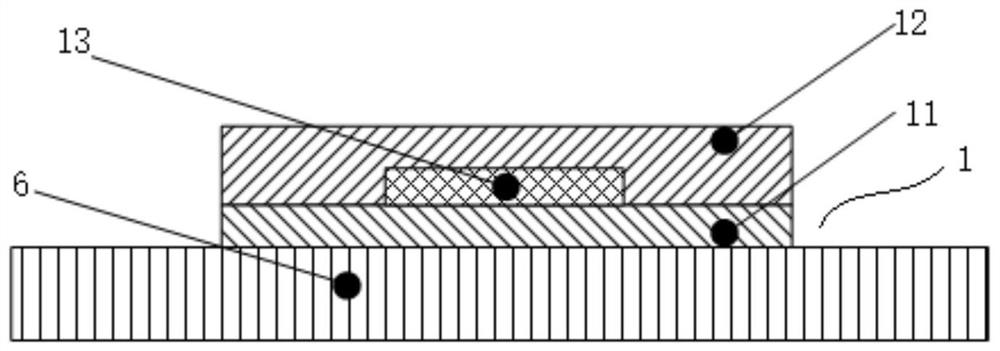

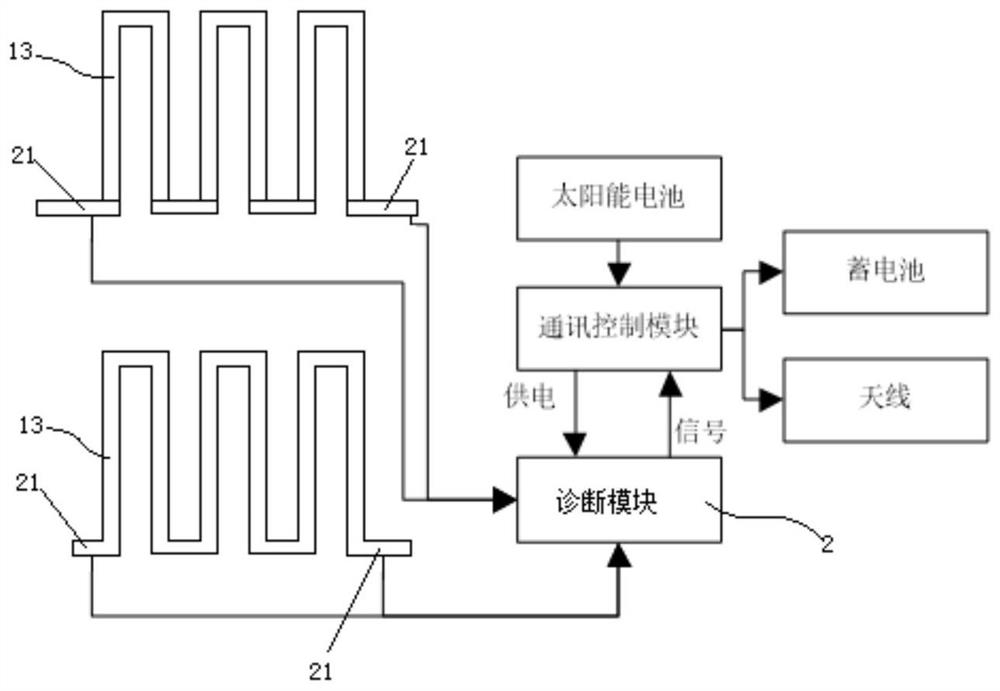

[0050] See figure 1 , figure 2 , image 3 , Figure 4 , a fan blade surface crack monitoring device, which includes a number of induction coatings 1 coated on the blade surface, a diagnostic module 2, a power supply 3 and a communication control module 4, the power supply 3 is electrically connected to the diagnostic module 2, and is used to give the diagnostic module 2 for power supply, and the diagnosis module 2 communicates with the external terminal 5 through the communication control module 3, and the external terminal 5 is a central control system or a remote monitoring system. The diagnostic module 2, power supply 3 and communication control module 4 are welded and fixed on the flexible board or PCB, packaged and fixed on the surface of the blade root or inside the blade, or integrated in the control box and installed on a suitable position such as the blade root cover.

[0051] The power supply 3 includes an external power supply and an internal power supply. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com