Industrial internet-based production intelligent monitoring method and system and a storage medium

An industrial Internet and intelligent monitoring technology, applied in manufacturing computing systems, biological neural network models, data processing applications, etc., can solve problems such as high labor costs, errors and errors, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

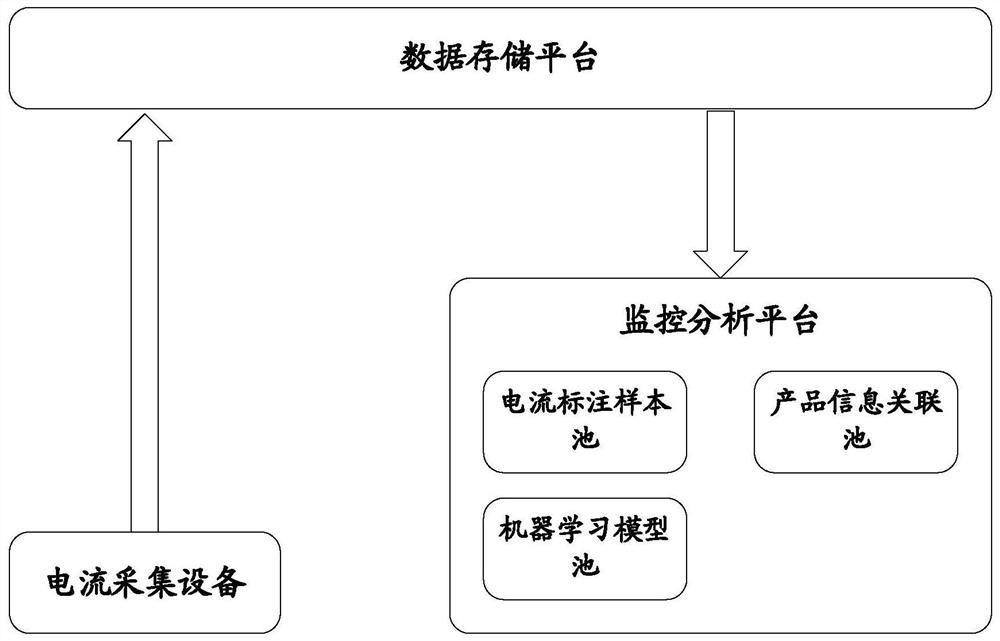

[0036] The industrial Internet-based production intelligent monitoring method provided by the present invention is realized based on the industrial Internet-based production intelligent monitoring system provided by the present invention. Therefore, this embodiment first describes the structure and functions of the production intelligent monitoring system in detail.

[0037] See figure 1 , The current acquisition device is connected to the main shaft motor of the production equipment drive system, and a group of current acquisition devices is associated with one production equipment, and the three-phase current data of the production equipment drive system main shaft motor is monitored and collected at intervals of 10 seconds.

[0038] The current acquisition device synchronously sends the collected current data to the data storage platform, and the data storage platform receives and stores the current information data, mainly including production equipment ID, current acquisit...

Embodiment 2

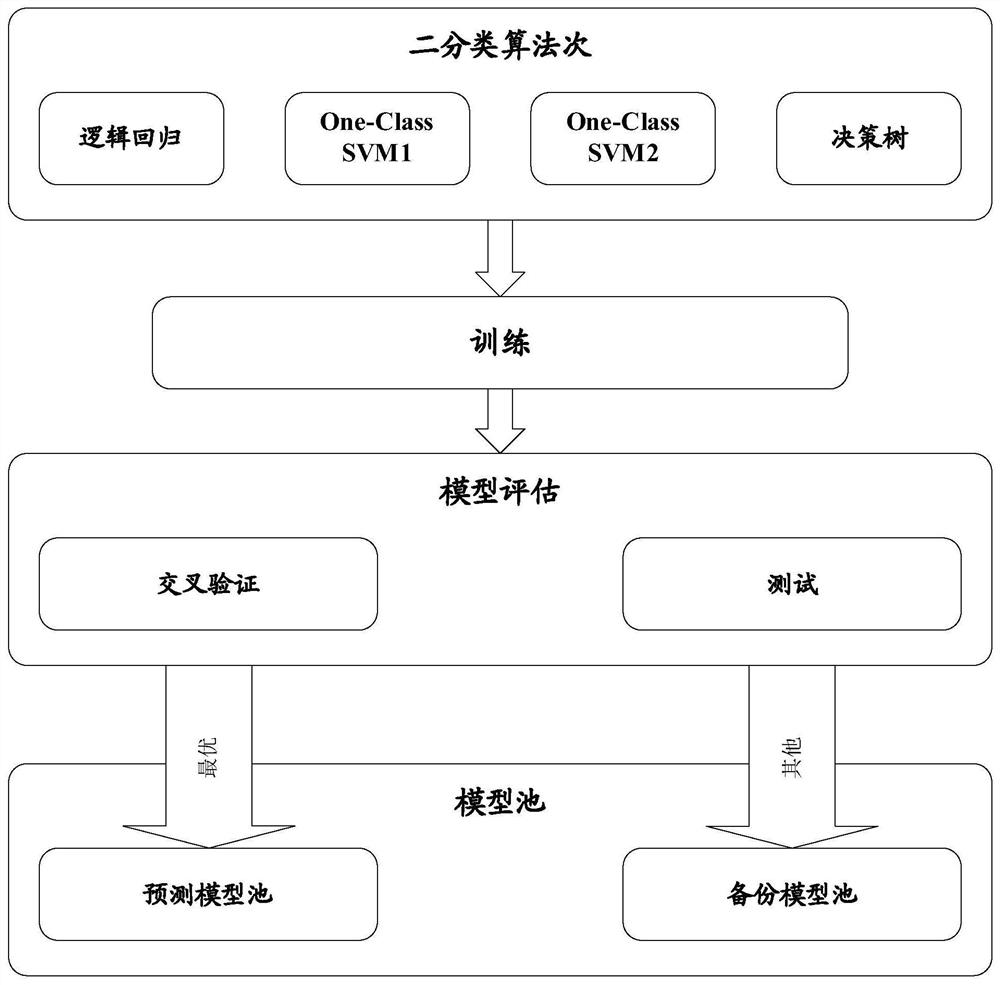

[0070] On the basis of the first embodiment above, this embodiment provides an industrial Internet-based production intelligent monitoring method, please refer to Figure 8 , mainly including the process of model building and the process of applying the model for capacity monitoring:

[0071] Among them, the model building process includes:

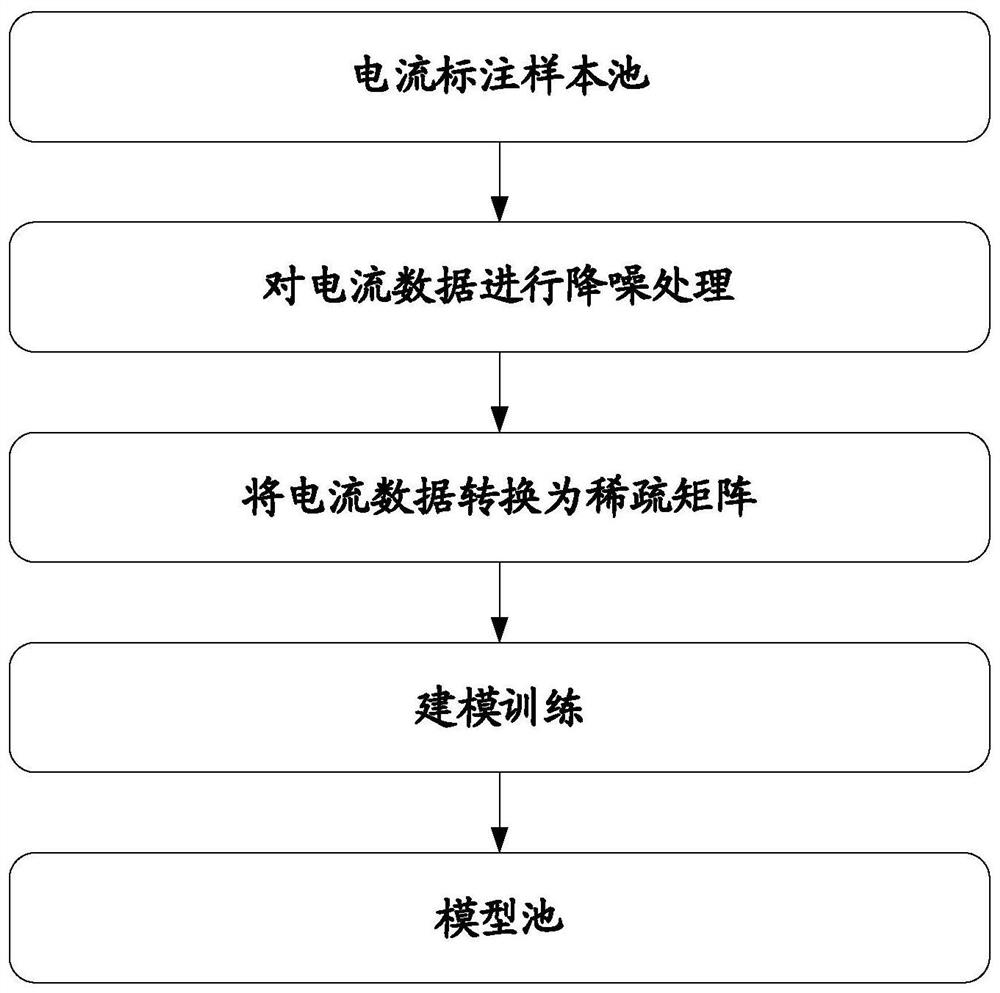

[0072] S10. Conduct current monitoring on the production equipment of the enterprise, obtain the current data of each production equipment, and perform associated labeling on the production products and production processes to which the current data belongs to form a current labeling sample pool;

[0073] In this embodiment, noise reduction processing is also performed on the current data.

[0074] In this embodiment, the current data is time-series data, including current values corresponding to different moments in the set period; after step S10, before step S20, it also includes converting the current data, including:

[0075] Conv...

Embodiment 3

[0110] On the basis of the second embodiment above, this embodiment provides a computer-readable storage medium, where one or more programs are stored in the computer-readable medium, and the one or more programs can be executed by one or more processors, In order to realize the steps of the industrial Internet-based production intelligent monitoring method as described in the second embodiment. For details, refer to the description in the second embodiment above, and details are not repeated here.

[0111] Obviously, those skilled in the art should understand that each module or each step of the present invention described above can be realized by a general-purpose computing device, and they can be concentrated on a single computing device, or distributed on a network formed by multiple computing devices , alternatively, they can be implemented with program codes executable by computing devices, thus, they can be stored in computer storage media (ROM / RAM, magnetic disks, opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com