Clean desulfurization modification method of light hydrocarbon fuel

A technology for light hydrocarbons and fuels, applied in the direction of fuel, solid fuels, liquid carbon-containing fuels, etc., can solve the problems of wasting precious resources, polluting the environment, and lack of research on the comprehensive utilization of light hydrocarbons, etc., to achieve delayed flame propagation speed and high vapor pressure , the effect of low pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

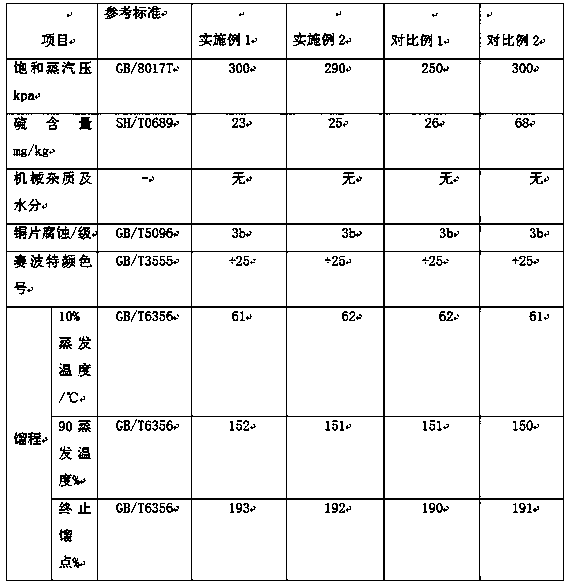

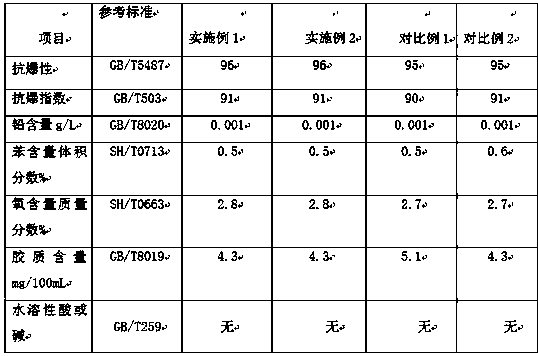

Embodiment 1

[0015] A clean desulfurization modification method for light hydrocarbon fuels, comprising the following steps: (1) putting 5 parts of light hydrocarbons with a purity of more than 98% into a clay pot, and then adding 0.2 parts of methylcyclopentadiene manganese tricarbonyl and 0.2 parts of tea polyphenols, and stirred for 40 minutes to obtain a mixed solution of A; (2) by weight parts, 39 parts of light hydrocarbons, 39 parts of methanol, 13 parts of dimethyl ether, 7 parts of 2-methyl-1-butene Parts, catalyst 5.1 parts, reaction temperature 425 ℃, reaction pressure is normal pressure; The weight space velocity of methanol is 2.2 / h, the weight space velocity of light hydrocarbon is 0.36 / h, high-purity nitrogen 350ml / min, reaction time 12 hours, (3) Put 49.9 parts of low-carbon light hydrocarbons in a stainless steel tank, then add 10 parts of composite additives into the stainless steel tank, and stir for 8 minutes to obtain B mixed liquid; (4) Add to A Add 7 parts of methyl ...

Embodiment 2

[0019] A clean desulfurization modification method for light hydrocarbon fuels, comprising the following steps: (1) putting 5 parts of light hydrocarbons with a purity of more than 98% into a clay pot, and then adding 0.2 parts of methylcyclopentadiene manganese tricarbonyl and 0.2 parts of quercetin, and stirred for 40 minutes to obtain a mixed solution of A; (2) by weight parts, 37 parts of light hydrocarbons, 37 parts of methanol, 11 parts of dimethyl ether, 5 parts of 2-methyl-1-butene Parts, catalyst 3.1 parts, reaction temperature 400 ℃, reaction pressure is normal pressure; The weight space velocity of methanol is 1.8 / h, the weight space velocity of light hydrocarbon is 0.22 / h, high-purity nitrogen 300ml / min, reaction time 6 hours, (3) Put 49.9 parts of low-carbon light hydrocarbons in a stainless steel tank, then add 5 parts of composite additives into the stainless steel tank and mix them, and stir for 5 minutes to get B mixed liquid; (4) Add to A Add 6 parts of methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com