Movable magnetic steel type self-driven magnetic levitation guide rail device and control method thereof

A technology of a guide rail device and a control method, which is applied in the field of a moving magnet steel type self-driven maglev guide rail device and its control field, can solve the problems that the guide rail cannot be self-driven, cannot actively adjust the gap with multiple degrees of freedom, and is difficult to guarantee high rigidity and straightness. , to achieve the effect of ensuring high rigidity, improving performance indicators, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

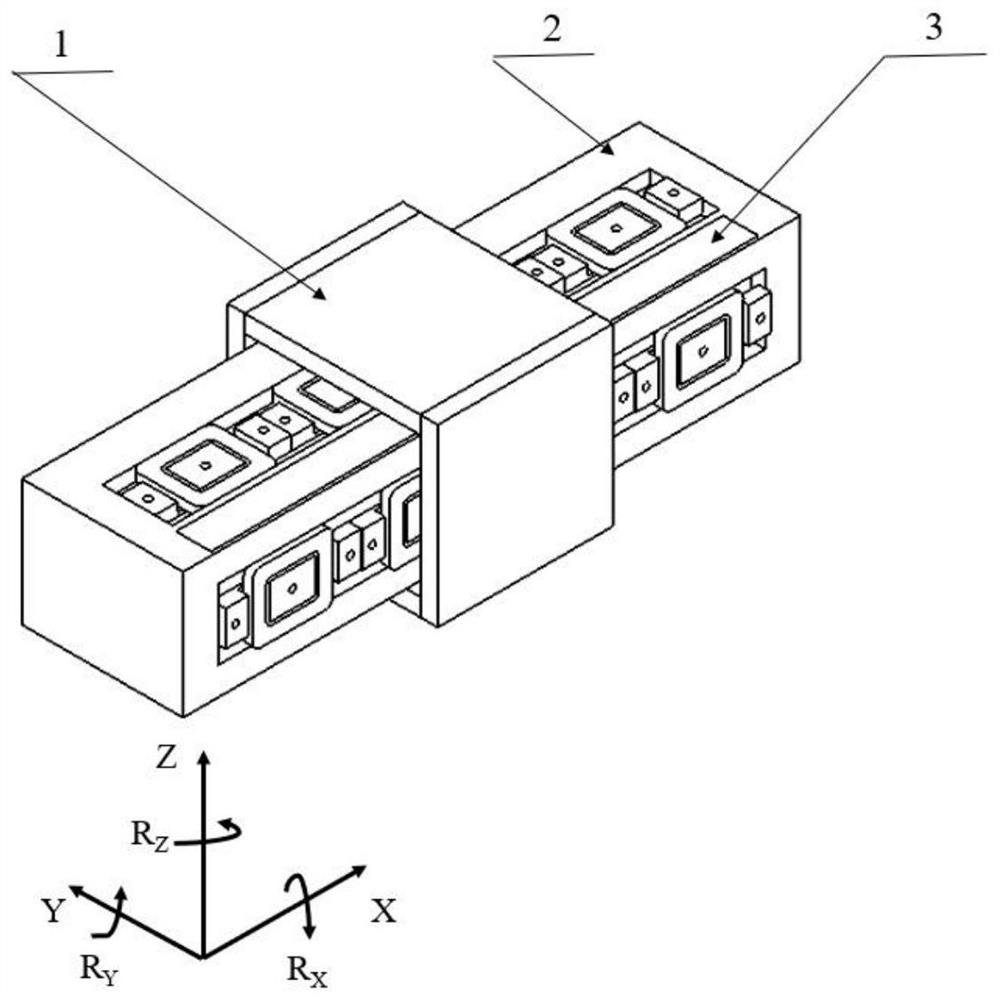

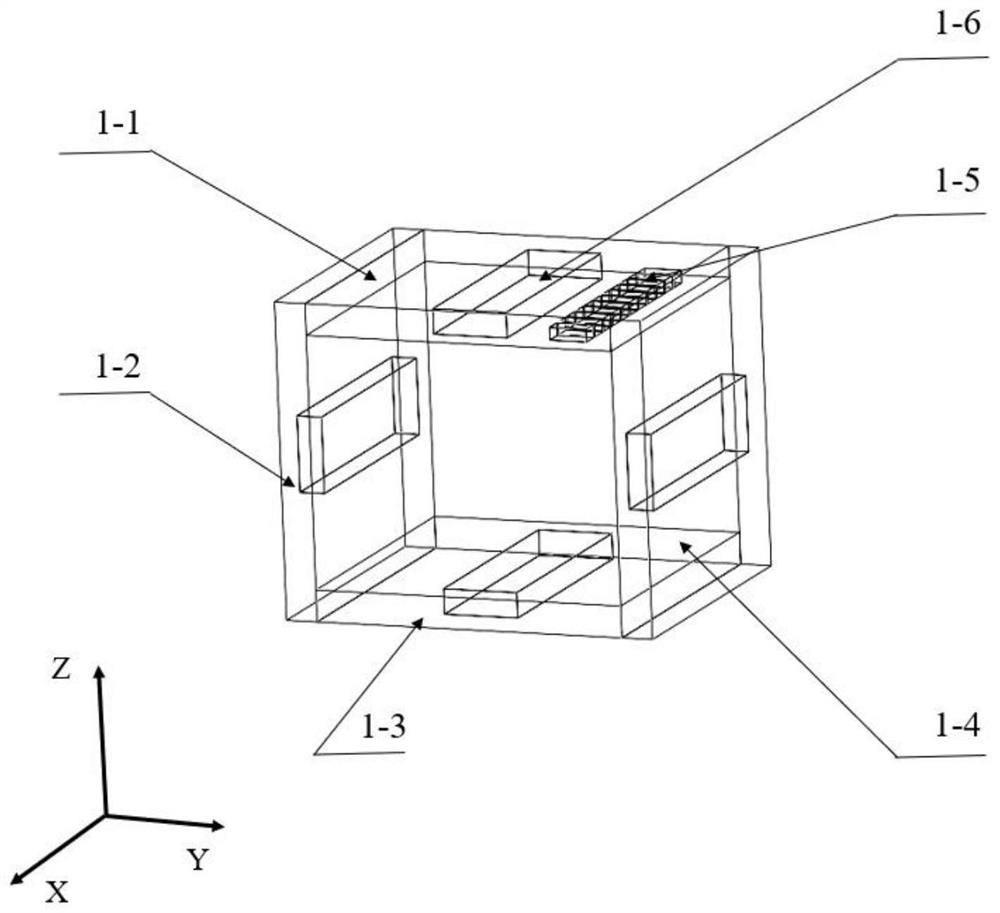

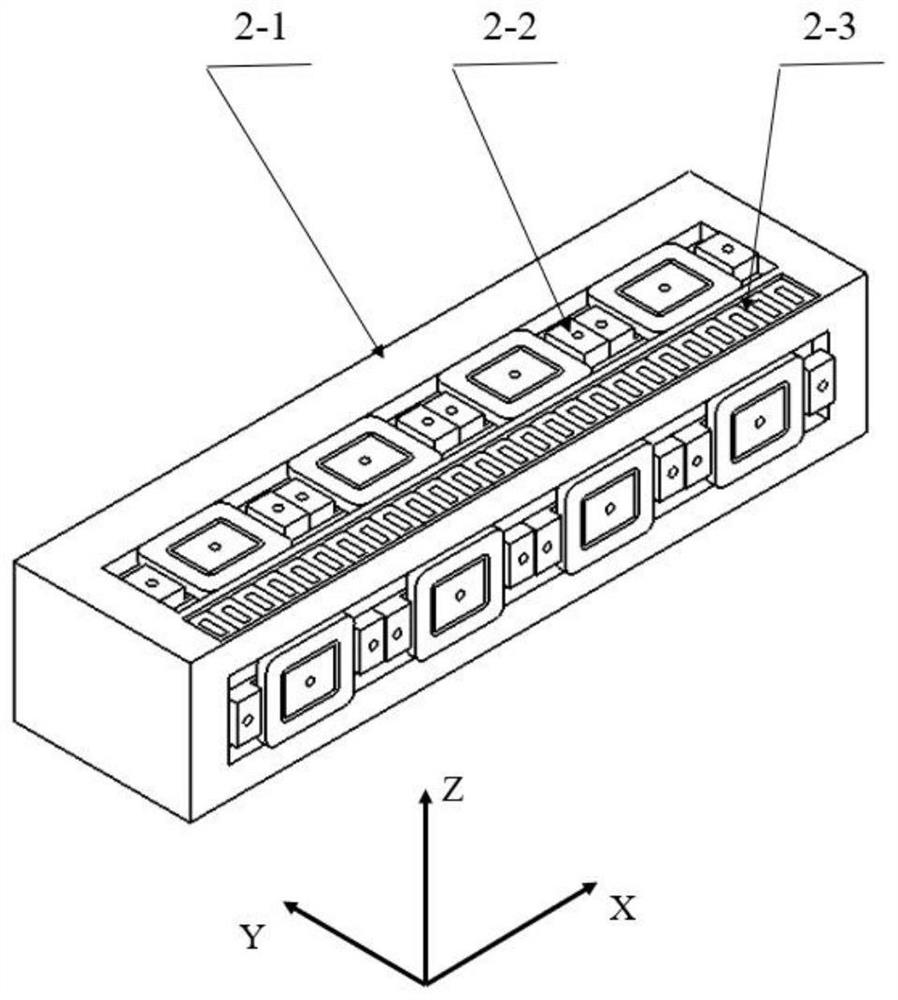

[0028] Specific implementation mode one: as Figure 1-Figure 4As shown, this embodiment discloses a moving magnet steel type self-driven maglev guide rail device, including a guide sleeve 1 and a guide shaft 2; the guide sleeve 1 is sleeved on the guide shaft 2; the guide sleeve 1 includes a permanent magnet 1-5, four guide sleeve support frames and four I-type electromagnets 1-6; the guide shaft 2 includes a guide shaft support frame 2-1, a coil winding 2-3 and a plurality of E-shaped components 2-2; Each of the E-shaped components 2-2 includes a primary coil 2-2-1, an induction coil 2-2-2, a bipolar electromagnet 2-2-3, an eddy current sensor 2-2-4 and two Hall Er element 2-2-5;

[0029] The four guide sleeve support frames are combined to form a square sleeve, and the middle parts of the four guide sleeve support frames are respectively packaged with I-type electromagnets 1-6, and the four I-type electromagnets 1-6 are all along the length direction of the guide shaft 2 A...

specific Embodiment approach 2

[0034] Specific implementation mode two: as Figure 1-Figure 4 As shown, this embodiment discloses a control method for realizing a moving magnet steel type self-driving maglev guide rail using the moving magnet steel type self-driving maglev guide rail device described in the specific embodiment, the control method is:

[0035] By adjusting the current size of the primary coils 2-2-1 of multiple E-type components 2-2 packaged on the upper and lower sides of the guide shaft 2, the primary coils 2-2-1 of multiple E-type components 2-2 on the same side are required to 1. The magnitude of the current should be the same (the magnitude of the current of the primary coil 2-2-1 of the multiple E-shaped components 2-2 on the upper and lower sides is different), so that the adjustment of the 1Z degree of freedom of the guide sleeve can be realized;

[0036] Adjust the current size of the primary coils 2-2-1 of multiple E-type components 2-2 packaged on the left and right sides of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com