High-flame-retardant environment-friendly PET film production equipment and method

A film preparation and environment-friendly technology, applied in the field of PET film, can solve problems such as affecting the production quality of PET film, film breaking of PET film, and inability to adjust width, etc., and achieve the effects of improving quality, improving production efficiency, and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

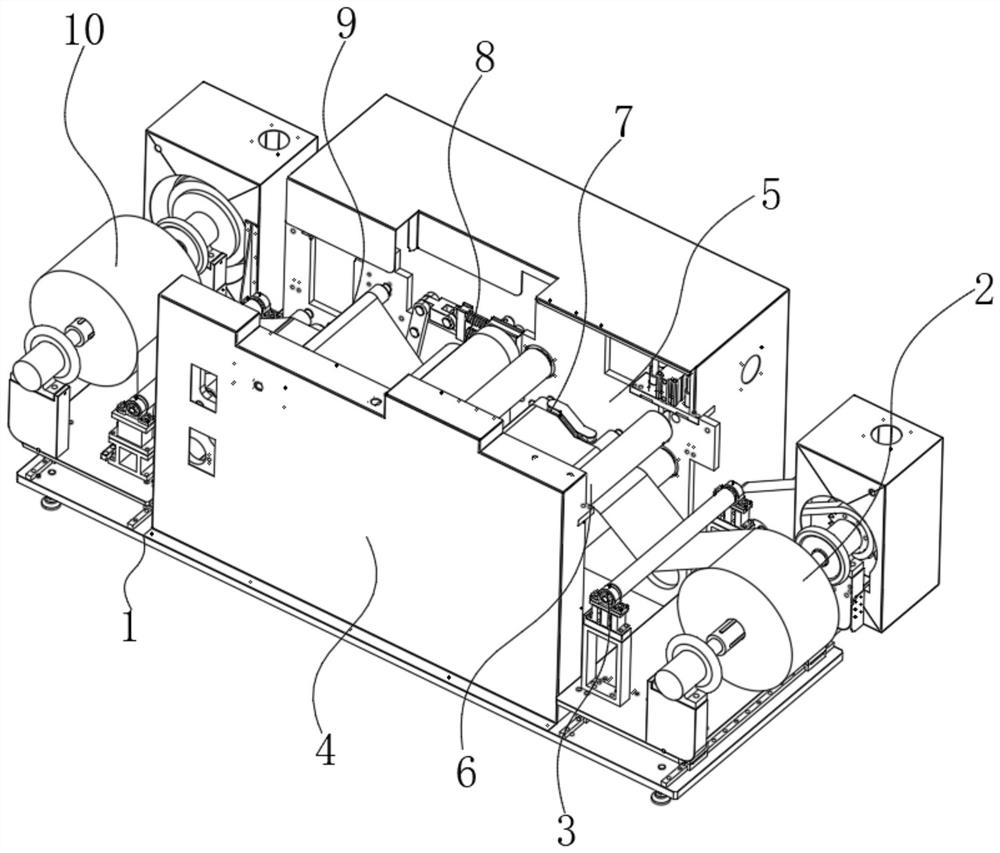

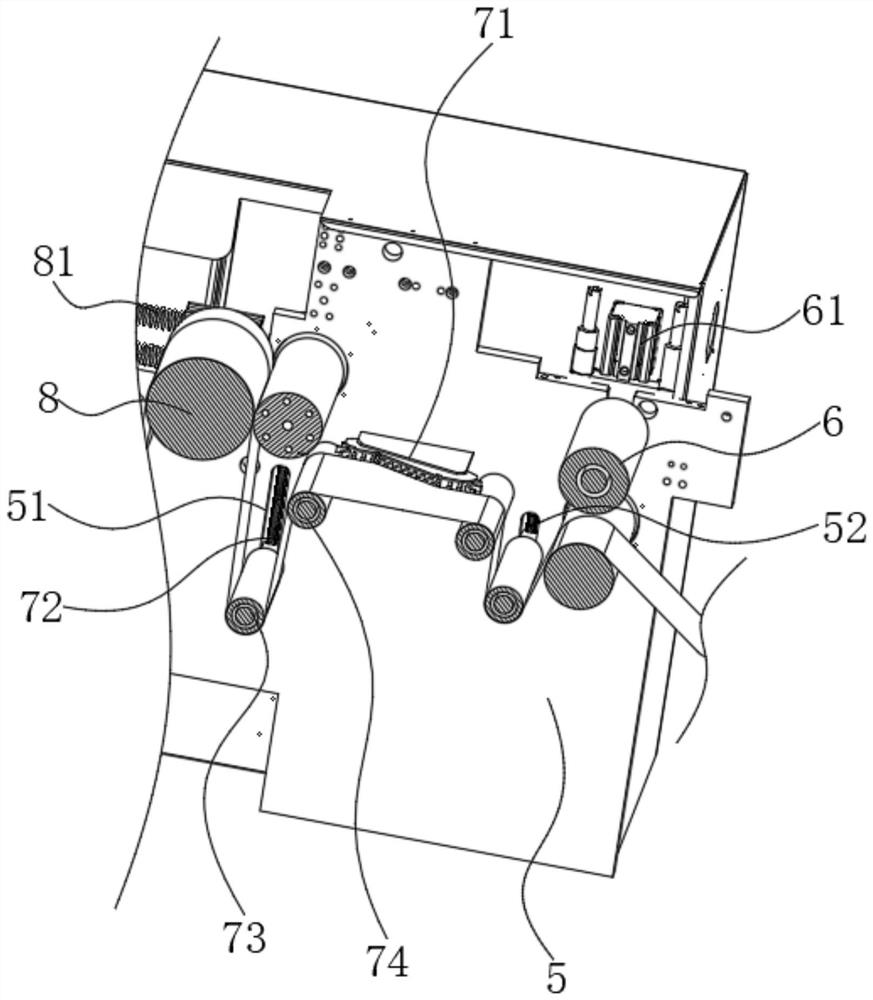

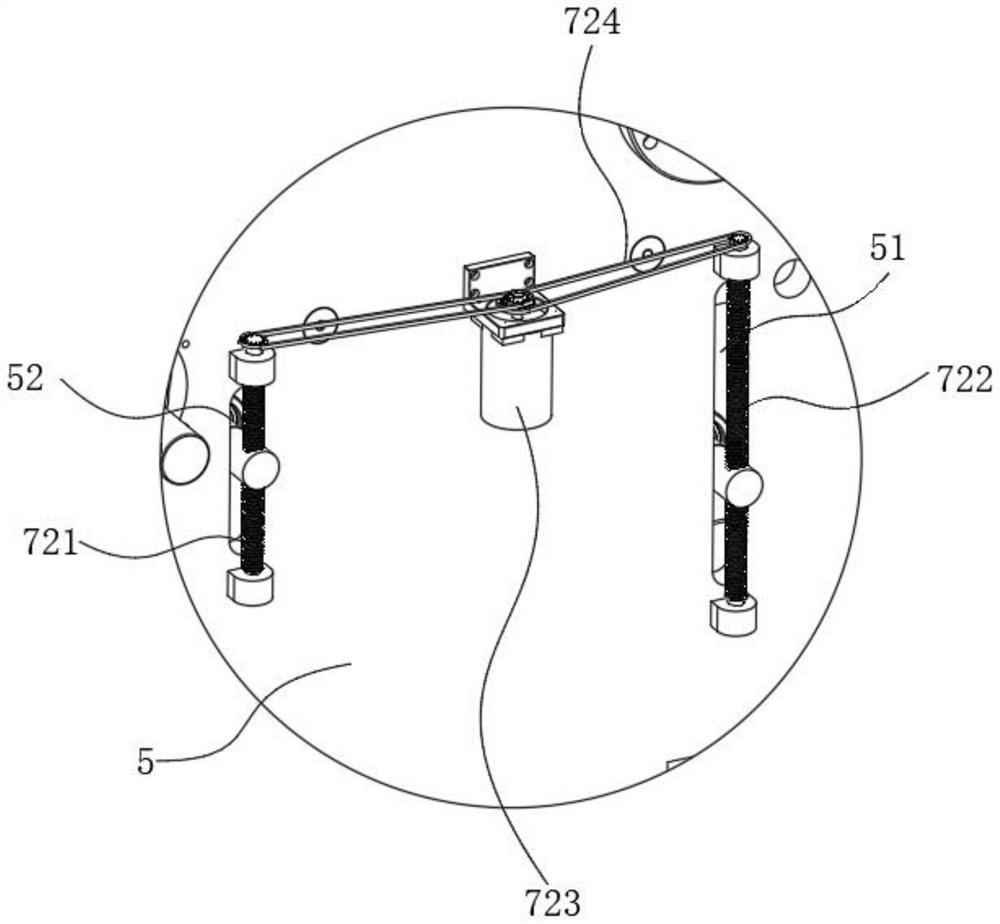

[0036] see Figures 1 to 5 , the present invention provides a high flame retardant environment-friendly PET film preparation equipment: comprising a base 1, a feeding roller 2, a preheating roller 3, a side plate 4, a side plate 2 5, a heating roller 6, a stretching assembly 7, a cooling roller 8. The driving roller 9 and the receiving roller 10, wherein the upper end surface of the base 1 is symmetrically provided with a feeding roller 2 and a receiving roller 10, and between the feeding roller 2 and the receiving roller 10, a fixed base is arranged between the feeding roller 2 and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com