High-efficiency low-emission time stratified scavenging small two-stroke gasoline engine

A low-emission, high-efficiency technology, applied in the direction of cylinders, carburetors, cylinder heads, etc., can solve the problems of exhaust gas pollution and unreasonable gas paths, and achieve the effect of improving ventilation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

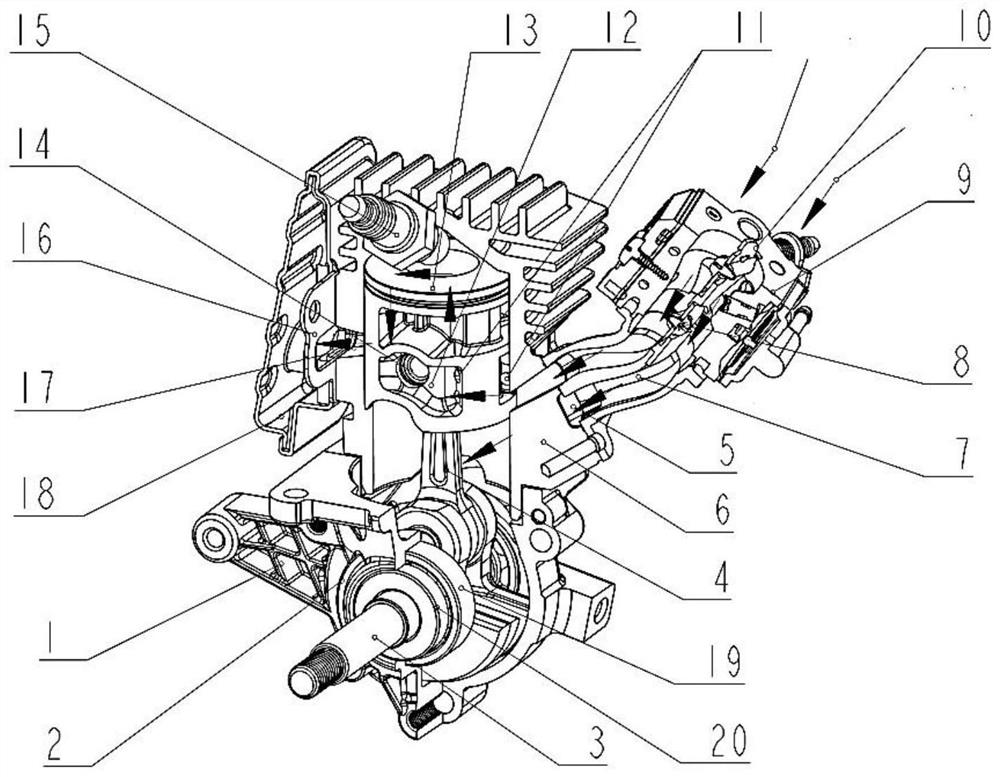

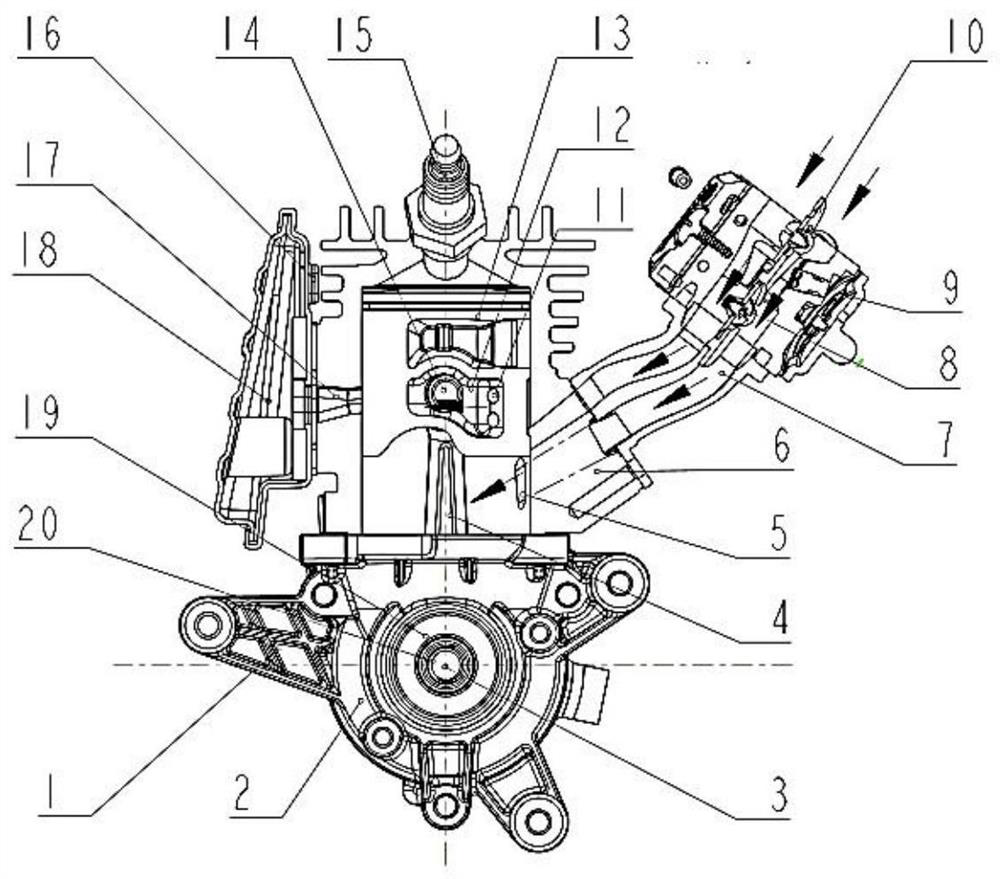

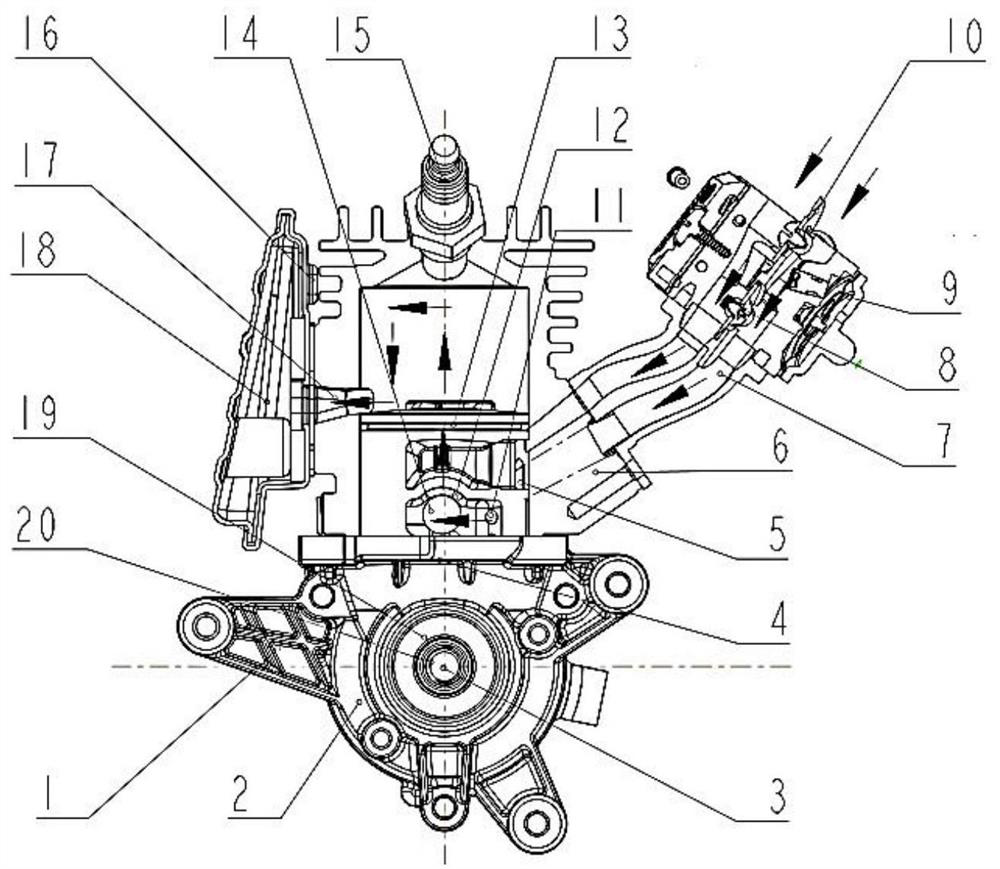

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0041] Such as Figure 1-Figure 7 As shown, a time-layered scavenging small two-stroke gasoline engine with high efficiency and low emission of the present invention includes a right crankcase 1, a left crankcase 2, a crankshaft 3, a connecting rod 4, a cylinder 6, an intake pipe 7, an accelerator 8, Double chamber carburetor 9, choke valve 10, pure air channel 11, gas storage cavity 12, piston 13, piston pin 14, spark plug 15, muffler gasket 16, exhaust port 17, muffler 18, bearing 19, Oil seal 20, left scavenging air cover plate 21, right scavenging air cover plate 22, left scavenging air port 23, right scavenging air port 24.

[0042] First, the right crankcase 1 and the left crankcase 2 are combined to form a crankcase chamber with an inner cavity, and the axially horizontal bearings 19 and oil seals 20 are respectively pressed into the crankcase c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com