Self-compensating micro-mirror surface driving device and compensation method for working voltage of self-compensating micro-mirror surface driving device

A technology of working voltage and driving devices, which is applied in the direction of instruments, optical components, optics, etc., can solve the problems that the torsion accuracy of the micromirror surface affects the control accuracy of optical signals, etc., and achieve the effect of improving device performance and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

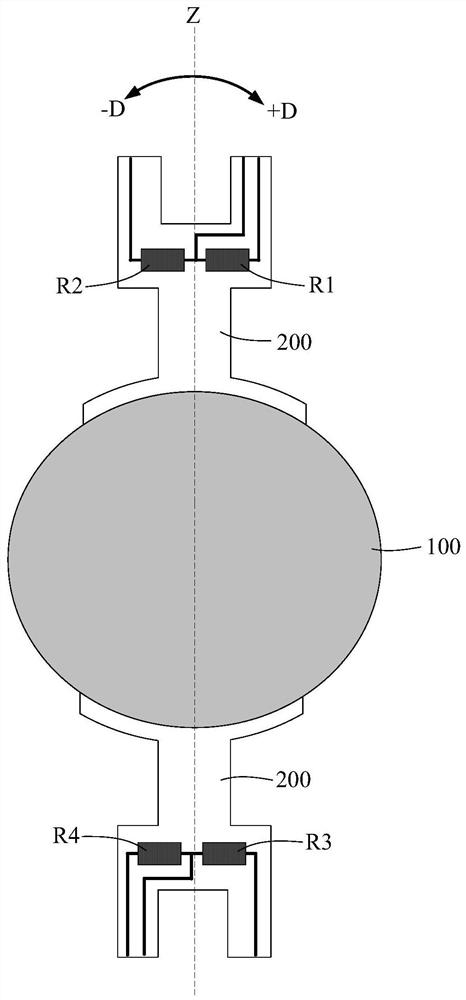

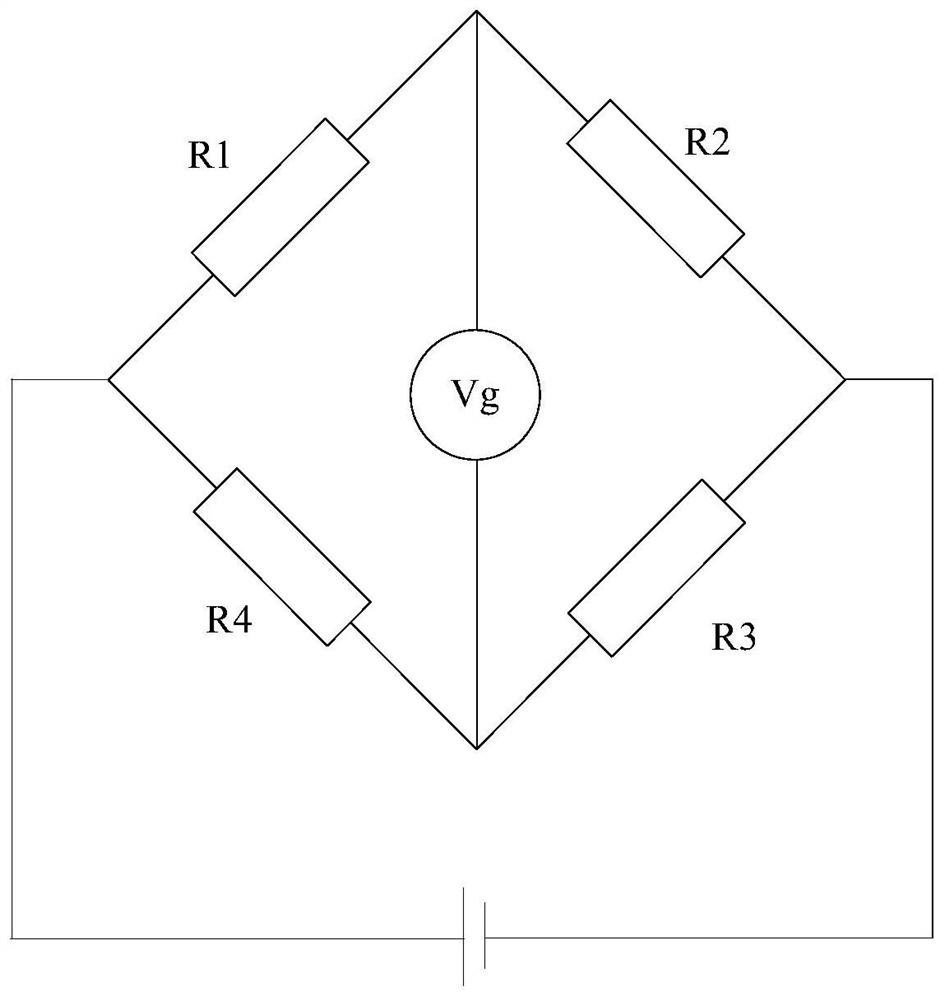

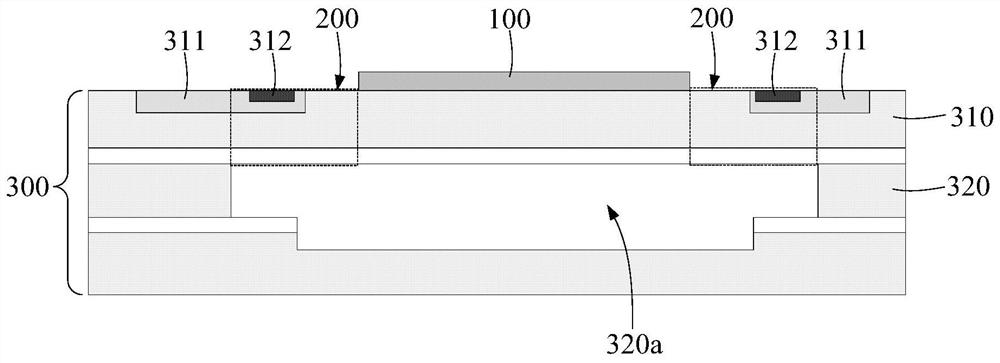

[0036] The micromirror drive device generally applies a working voltage to make the drive component drive the micromirror to twist a predetermined angle during its working process. Therefore, the control of the micromirror's twist angle by the micromirror drive device in the working process directly reflects the device. performance.

[0037] The inventors of the present invention have found that an important factor affecting the torsion accuracy of the micromirror is that there is still a slight twist of the micromirror under the condition of no operating voltage, which will cause deviations in the twisting angle of the micromirror under a predetermined operating voltage .

[0038] For this reason, the present invention provides a kind of compensation method of the operating voltage of micromirror surface driving device, comprising: detecting the deflection direction and deflection angle of micromirror surface under no operating voltage, according to the deflection direction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com