Molded steel pouring process

A steel casting and process technology, applied in the field of die-cast steel ingots, can solve problems such as loss, environmental pollution, and emission, and achieve the effects of reducing secondary oxidation of molten steel, reducing costs, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

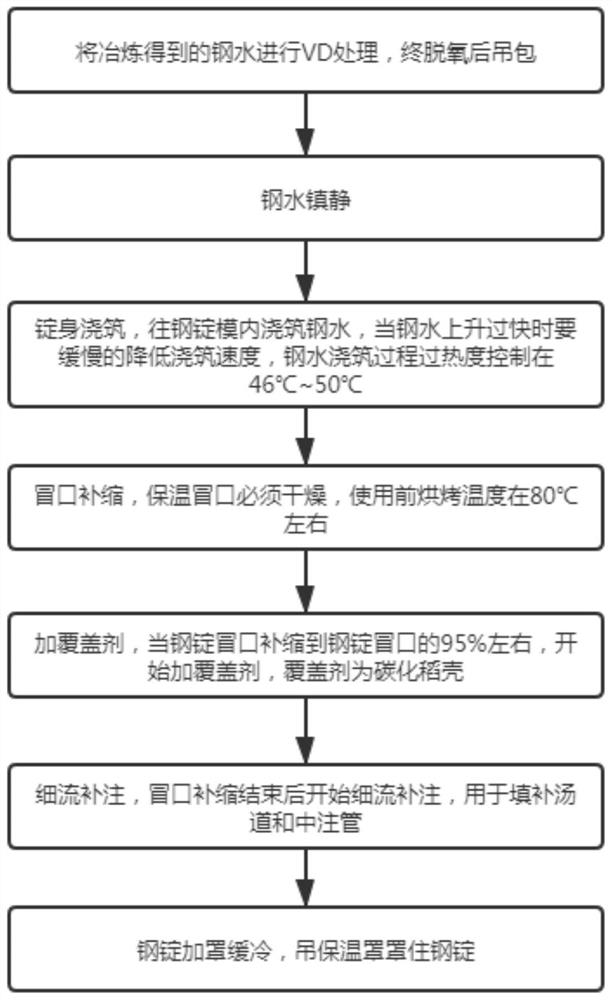

[0026] refer to figure 1 , propose an embodiment of the mold casting steel pouring process of the present invention:

[0027] A die casting steel pouring process is characterized in that its process flow is as follows:

[0028] 1) Carry out VD treatment on the molten steel obtained from smelting, and hang the ladle after final deoxidation;

[0029] 2) Molten steel calming;

[0030] 3) Pouring the ingot body, pouring molten steel into the ingot mould, slow down the pouring speed when the molten steel rises too fast, and control the superheat of the molten steel pouring process at 46°C to 50°C;

[0031] 4) Riser feeding, insulation riser must be dry, and the baking temperature before use is about 80°C;

[0032] 5) add covering agent, when steel ingot riser is fed to about 95% of steel ingot riser, begin to add cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com