Intelligent welding device

A welding device and intelligent technology, applied in the field of intelligent welding devices, can solve the problems of welding slag splashing, high brightness, inconvenient observation, injury to staff, etc., and achieve the effects of improving work efficiency, protecting eyes and body safety, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

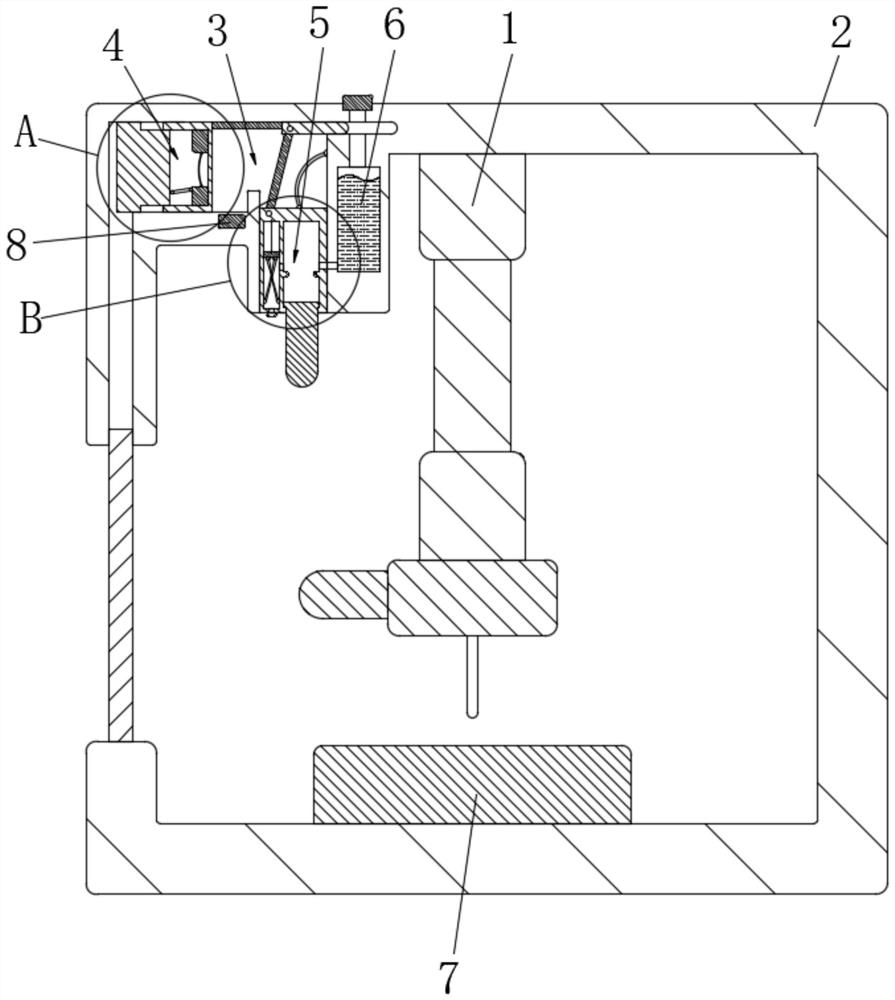

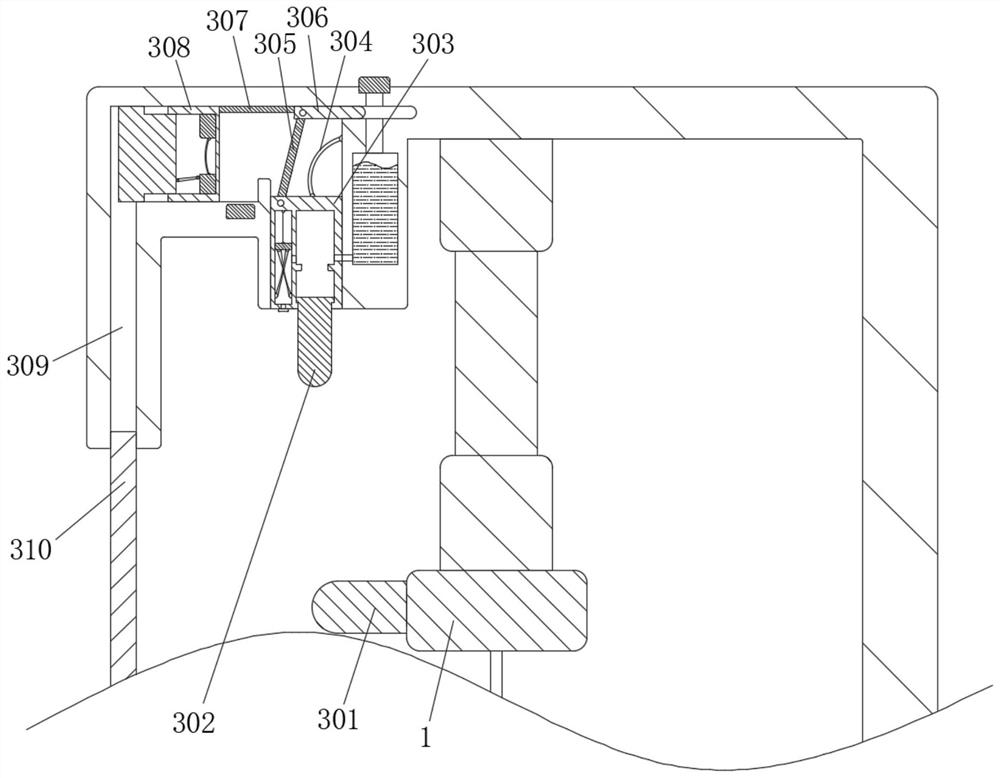

[0022] like Figure 1-5 As shown, the present invention provides a technical solution: an intelligent welding device, including a box body 2, a cap is provided on the top of the box body 2, a box door is hinged on the front side of the box body 2, and a welding part 7 is arranged on the bottom of the inner wall of the box body 2, The top of the inner wall of the box body 2 is fixedly connected to the spot welding machine 1, the inside of the box body 2 is provided with a water storage tank 6, the top of the water storage tank 6 is provided with a water inlet groove, and one side of the water storage tank 6 is provided with a round hole, and the inner wall of the box body 2 is fixedly connected with a neodymium Magnet A8, the inside of the box body 2 is provided with a welding observation protection mechanism 3, by arranging the welding observation protection mechanism 3, when the spot welder 1 is welding the weldment 7, the glass slide plate 310 can automatically descend to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com