Tenon anchor assembly type track unit and tenon anchor assembly type track with same

A prefabricated and track technology, applied in the field of rail transit, can solve the problems of difficult construction of self-compacting concrete layer, poor stability of track structure, rapid repair of track structure, etc., and achieves difficult construction quality hidden dangers, good stability, and overall cooperative work The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

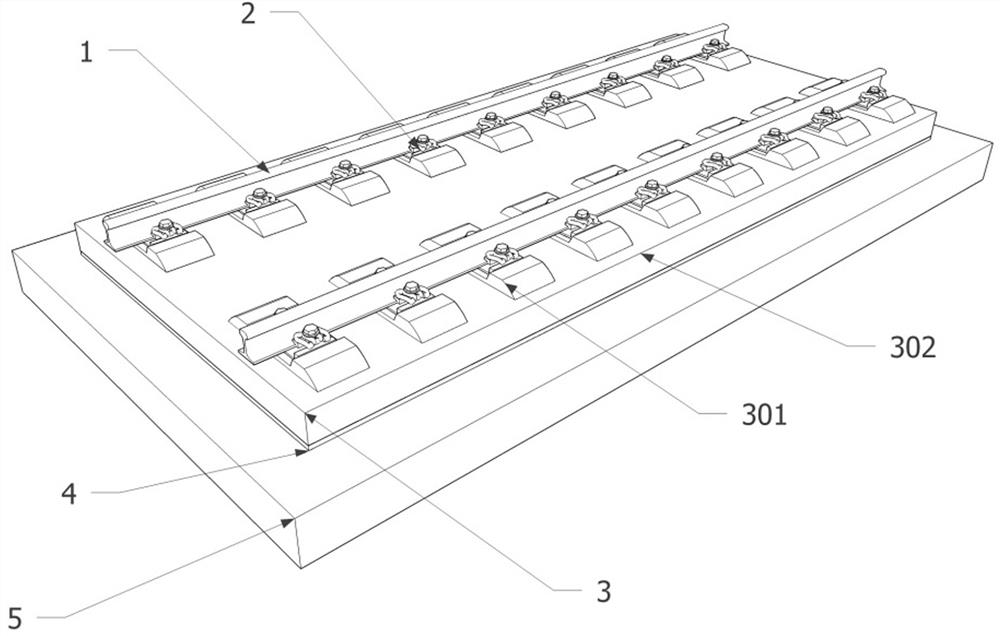

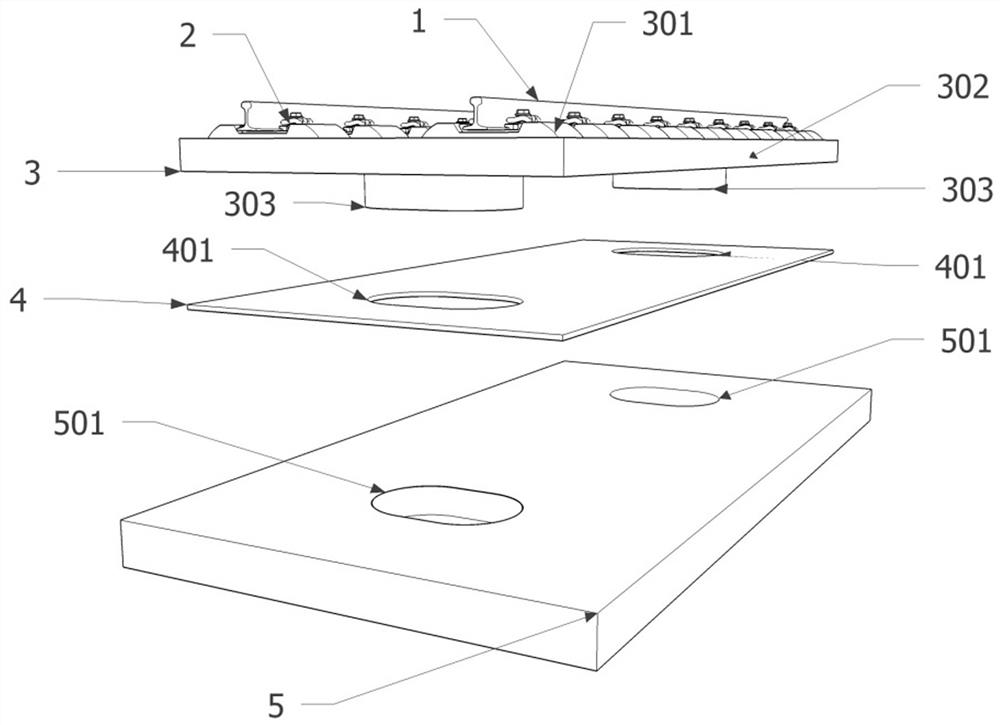

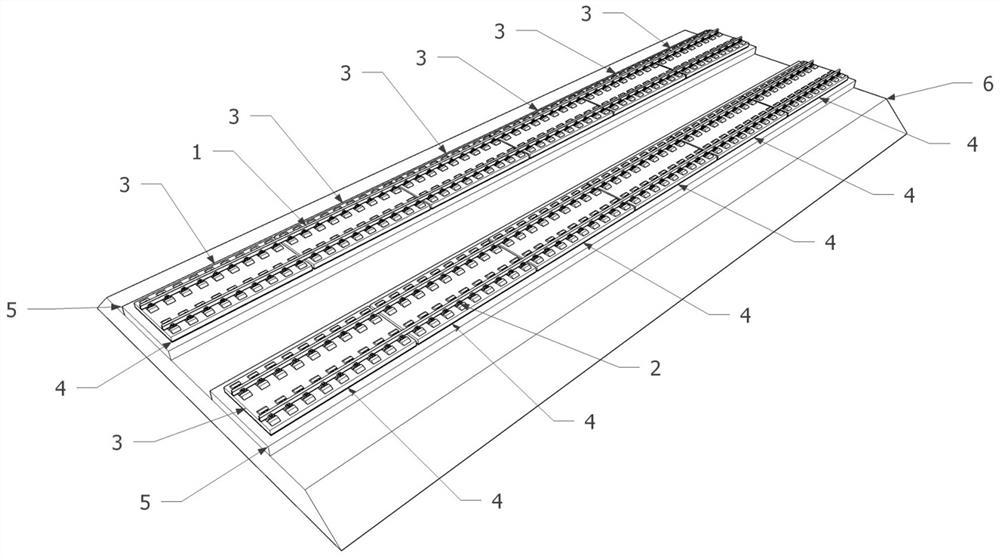

[0052] refer to figure 1 and figure 2 , the preferred embodiment of the present invention provides a mortise and anchor assembled track unit, including: a prefabricated track plate group 3 for guiding the train to run and transmitting loads, an isolation layer 4 for isolation, and cast-in-place molding to play a supporting role It is also used to level the base plate 5 of the mortise-anchor assembled track unit, the track plate group 3, the isolation layer 4, and the base plate 5 are stacked sequentially from top to bottom along the height direction, and the track plate group 3, the isolation layer 4, and The base plates 5 respectively extend along the running direction of the train. The mortise and anchor assembled track unit also includes a connection structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com