Cascade absorption type system

An absorption type and absorber technology, which is applied in the field of cascade absorption type systems, can solve the problems of high energy consumption, low integration, and large floor space, so as to reduce energy consumption, reduce power, and reduce floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

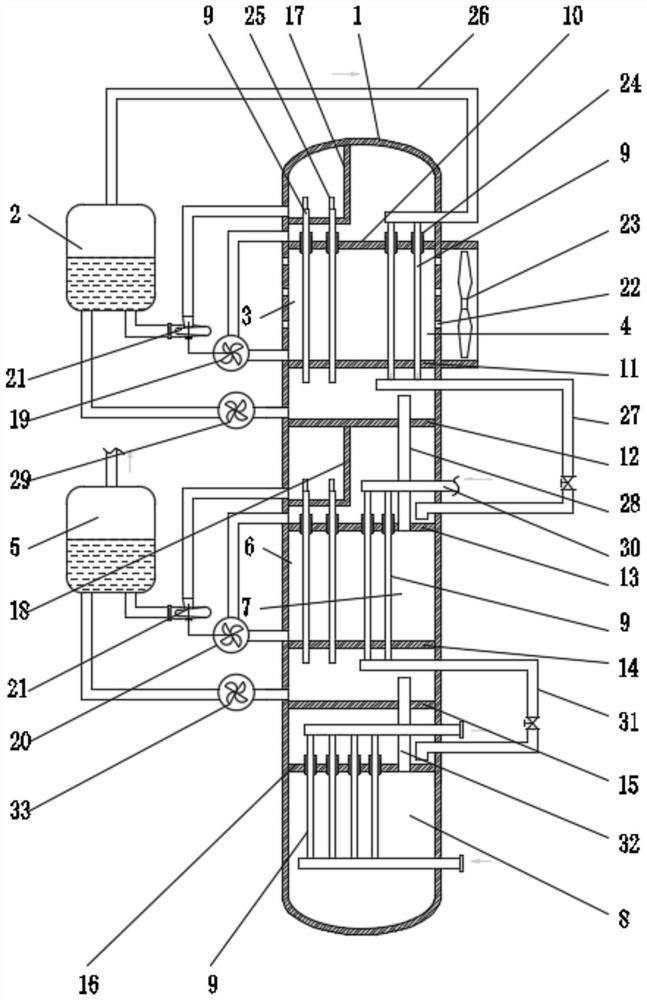

[0026] Such as figure 1 As shown, in this embodiment, the shell side of the primary absorber 3 and the primary condenser 4 use circulating water, the shell side of the secondary absorber 6 and the secondary condenser 7 use liquid refrigerant, and the secondary evaporator The shell side of 8 uses liquid refrigerant, the tube side of heat exchange tube 9 of primary absorber 3 and secondary absorber 6 uses lean solution, and the tube side of heat exchange tube 9 of primary condenser 4 and secondary condenser 7 runs through Gaseous refrigerant, the heat exchange tube 9 tube side of the secondary evaporator 8 carries the refrigerant.

[0027] Specifically, the heat exchange tubes 9 of the primary absorber 3, the primary condenser 4, the secondary absorber 6, the secondary condenser 7, and the secondary evaporator 8 are all equipped with liquid distribution tubes outside the tubes near the corresponding partitions at the upper end. 24, the circulating water inlet of the first-stage...

Embodiment 2

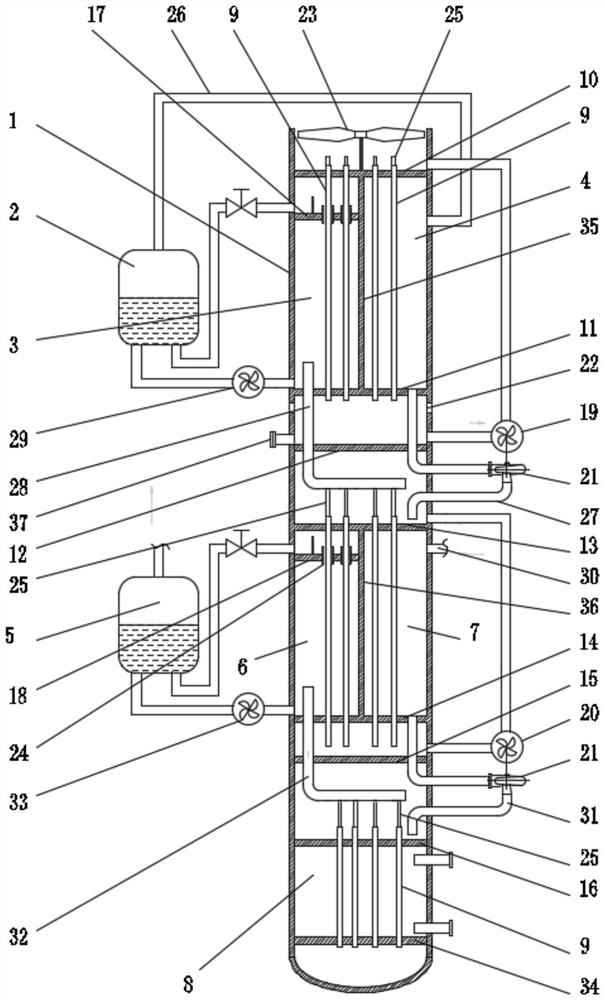

[0032] Such as figure 2 As shown, in this embodiment, the heat exchange tubes 9 of the primary absorber 3 and the primary condenser 4 run through circulating water, and the heat exchange tubes 9 of the secondary absorber 6 and the secondary condenser 7 run through the tubes Circulating liquid refrigerant, the heat exchange tube 9 of the secondary evaporator 8 passes the refrigerant, the shell side of the primary absorber 3 and the secondary absorber 6 passes the lean solution, the primary condenser 4, and the secondary condenser 7 The shell side of the secondary evaporator 8 uses the refrigerant, and the shell side of the secondary evaporator 8 uses the secondary refrigerant.

[0033]Specifically, the eleventh partition 35 is vertically located between the first partition 10 and the second partition 11, and is used to separate the heat exchange tube 9 area of the primary absorber 3 and the primary condenser 4, and the twelfth partition The plate 36 is vertically located be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com