A press-fitting device for a semiconductor device and a pressure detection method thereof

A press-fitting device and semiconductor technology, applied in semiconductor/solid-state device manufacturing, measuring devices, force/torque/power measuring instruments, etc. Reduce and other problems, to avoid the effective pressure reduction, reduce the manual operation torque, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments of the description, but it does not

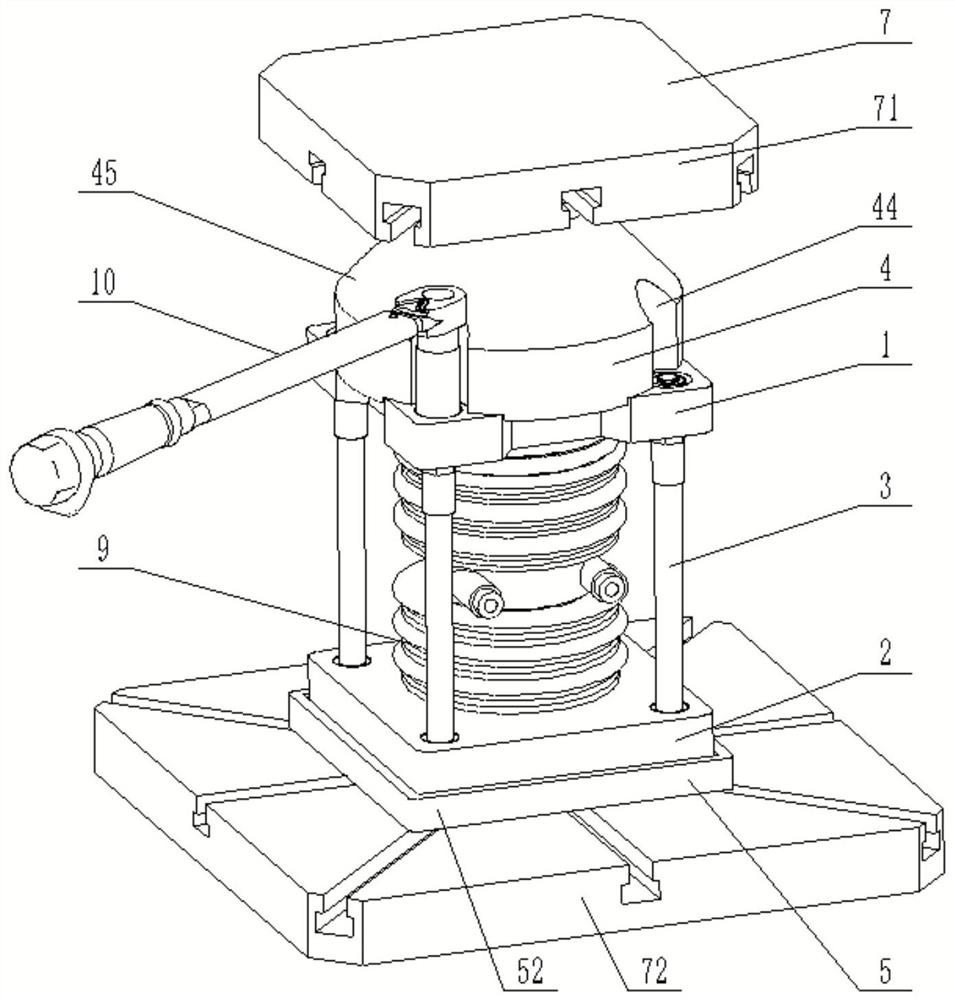

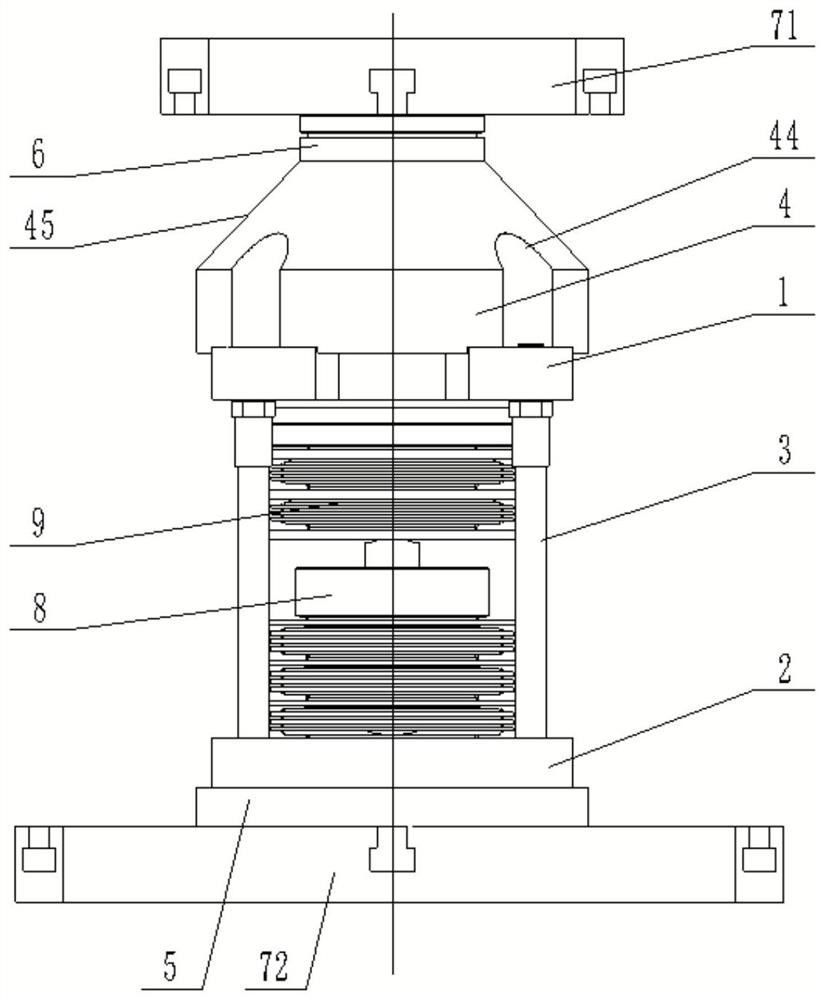

[0040] FIGS. 1 to 6 show an embodiment of a press-fitting device for a semiconductor device of the present invention, which is applied to press-fitting

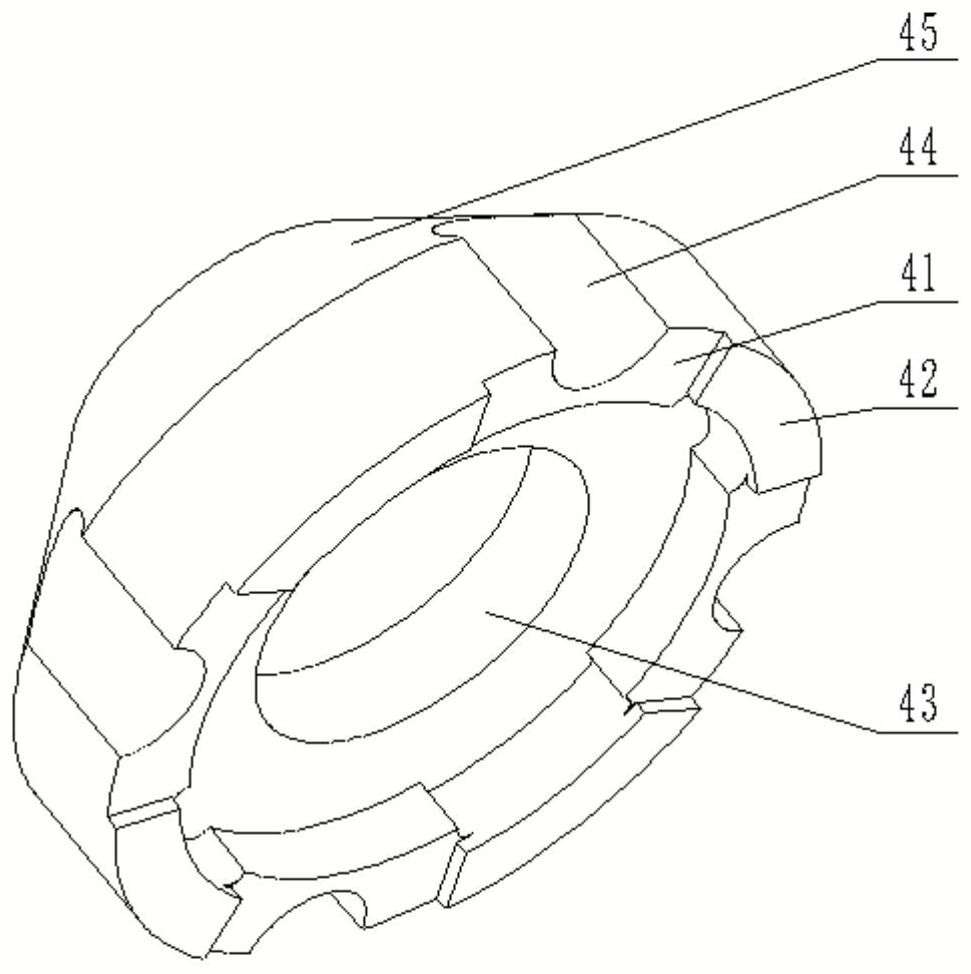

[0041] As shown in FIG. 1 and FIG. 2, the pressure plate tooling includes an upper positioning member 4 and a lower positioning member 5. Among them, the upper positioning member 4 is provided with an upper

[0043] The structure of the upper platen limit portion 42 and the lower platen limit portion 52 of the present invention and the setting position are based on the positioning member.

[0049] In this embodiment, the adjustment components 3 are four groups, and the four groups of the adjustment components 3 are respectively arranged at the four corners of the lower pressure plate 2 of the upper pressure plate 1.

[0051] As shown in FIG. 6 , the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com