Preparation and calculation method of brazed joint fracture toughness sample

A brazed joint and fracture toughness technology is applied in the field of sample preparation and calculation of the fracture toughness of brazed joints, and can solve the problems of crack propagation of brazed joints, component fracture, and difficulty in obtaining the mechanical properties of micro-areas at room temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further elaborated below in conjunction with accompanying drawing:

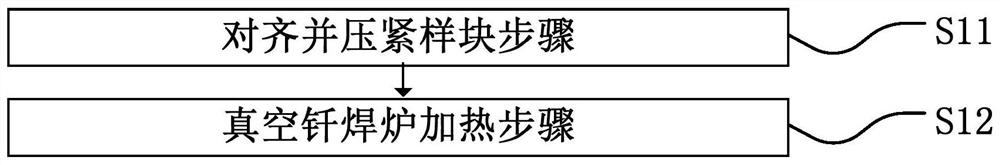

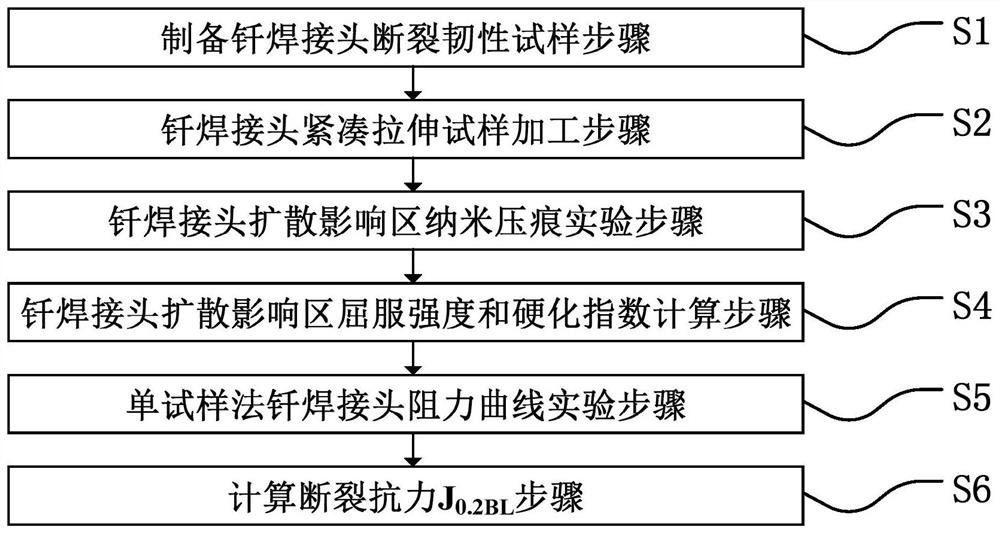

[0061] The present invention proposes a method suitable for the preparation of fracture toughness samples of micro brazed seams of brazed joints, as well as the resistance curve and fracture resistance J 0.2BL value calculation method, where figure 1 , figure 2 The schematic flow charts of the method for preparing and calculating the fracture toughness sample of the brazed joint according to the present invention are respectively shown.

[0062] Among them, such as figure 1 As shown, the preparation method of the fracture toughness sample of the brazed joint adopts the method of prefabricating the initial crack with the solder resist and reprocessing, and q fracture toughness samples can be prepared at the same time, which specifically includes S11-S12.

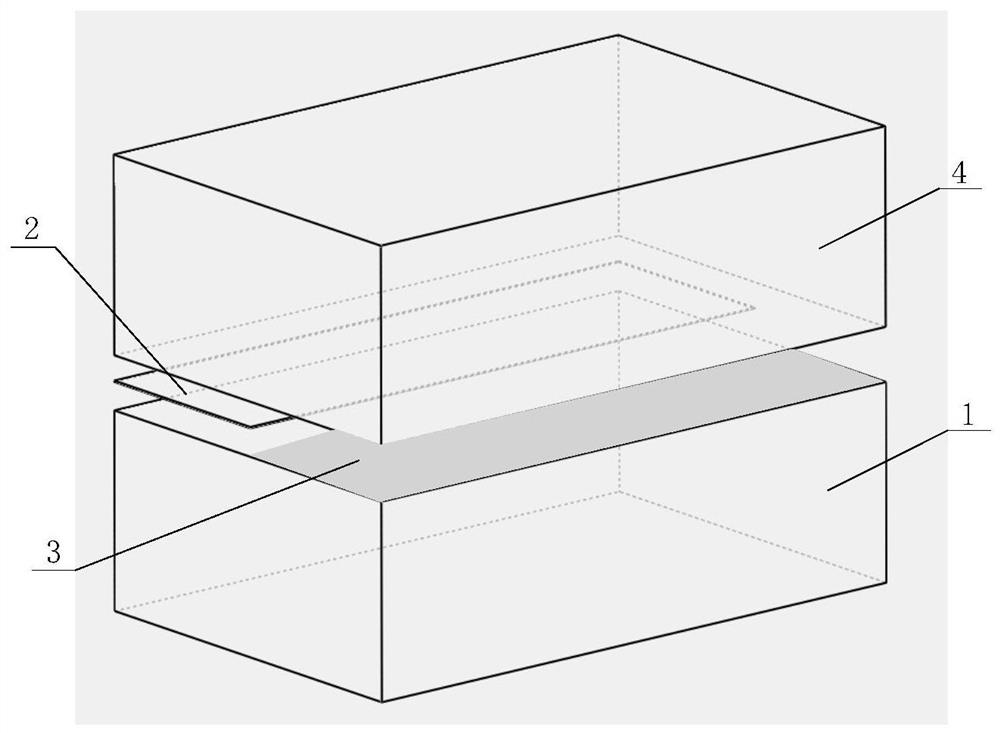

[0063] S11, the step of aligning and compressing the sample block, combining image 3 , prepare two upper sample b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com