Domain optimization-based decomposition furnace outlet temperature prediction control method in cement sintering system

A technology of model predictive control and cement industry, which is applied in the direction of adaptive control, general control system, control/regulation system, etc. It can solve problems such as untimely update and unreasonable manual setting, so as to reduce energy consumption and minimize energy consumption. Invest in and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention is aimed at the time-lag and randomness of the cement industry process itself, and it is difficult to control it with traditional control methods. At present, the existing research methods in this technical field are difficult to solve the variable coupling under the complex working conditions of the cement firing system. A predictive control method based on domain optimization for the outlet temperature of the calciner in the cement firing system was developed based on problems such as time-varying delay and time-varying time delay.

[0057] Below in conjunction with embodiment the present invention is described in further detail:

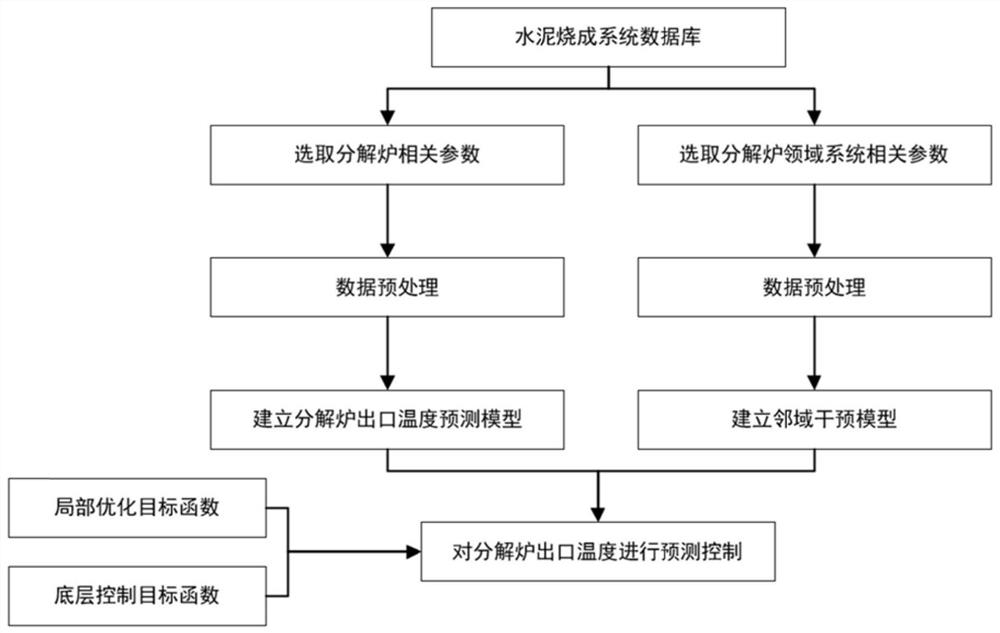

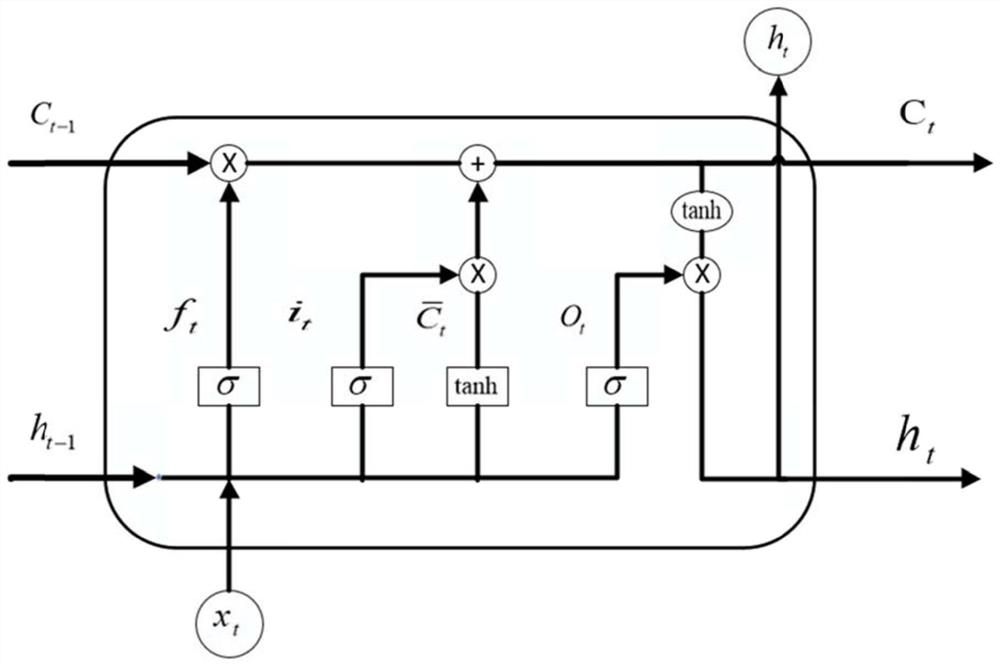

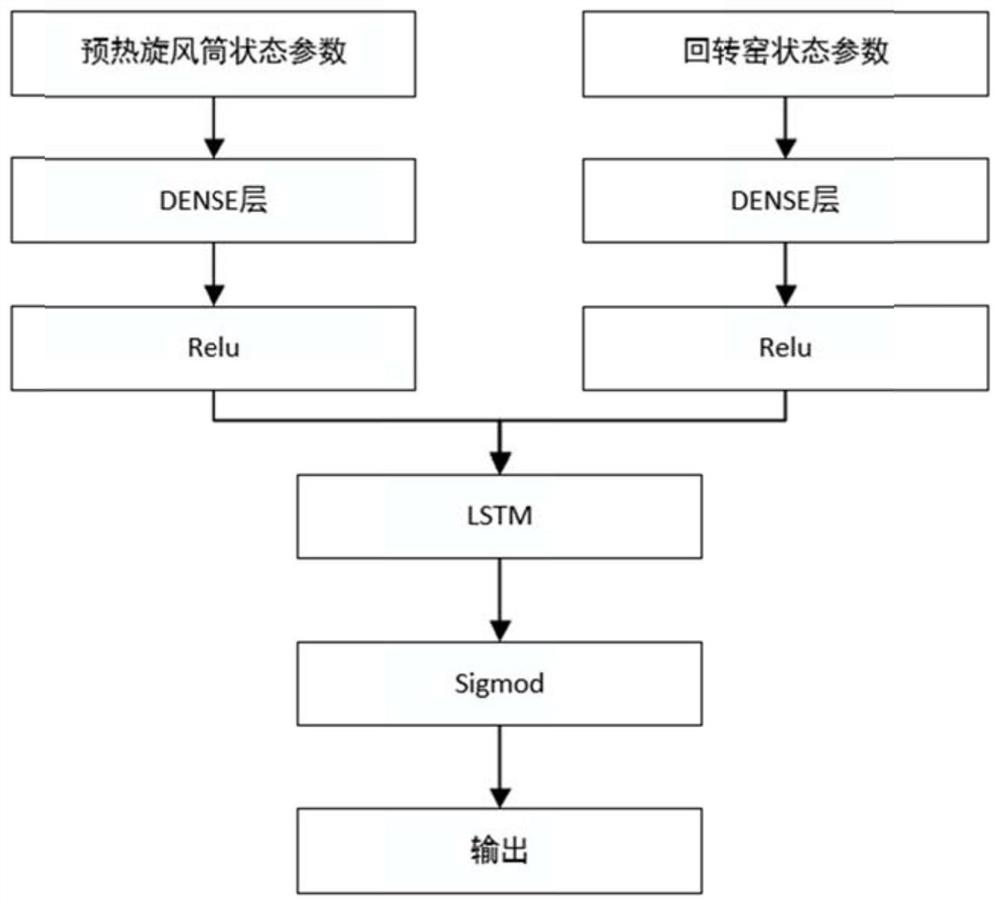

[0058] figure 1 It is a framework flow chart of the present invention, which includes: building a calciner outlet temperature prediction model based on a long-short-time neural network; building a real-time neighborhood information intervention model based on a long-short-time neural network; using domain information t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com