Bearing fault diagnosis method in transmission part of mine hoist

A technology for mine hoists and transmission components, applied in special data processing applications, complex mathematical operations, instruments, etc., can solve problems such as difficult diagnosis of early bearing failures, improve reliability and safety, facilitate calculations, and install equipment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0035] A method for diagnosing a bearing fault in a transmission part of a mine hoist, comprising the following steps:

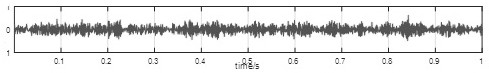

[0036] (1) Install a vibration acceleration sensor on the above-mentioned bearing, and collect vibration signals under normal state, inner ring fault, rolling element (ball) fault and outer ring fault at a sampling frequency of 12k (the time domain of the collected original signal Such as figure 1 shown), the collected analog signal is conditioned by the MAX3082 high-speed transceiver and converted into a standard signal, and then the standard signal is A / D converted to make it a digital signal, and then the converted digital signal is communicated to TMS320DM642DSP processor, real-time processing of digital signals.

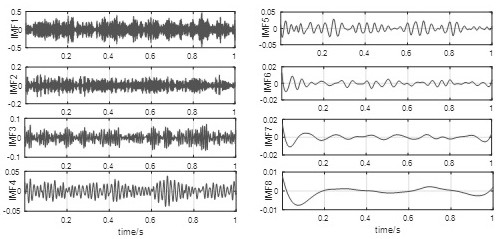

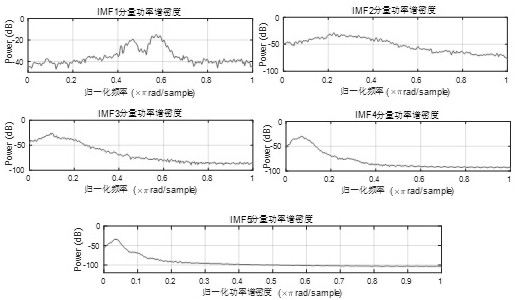

[0037] (2) Use the ensemble empirical mode decomposition method to extract data from the real-time processed digital signal,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com