Method for improving internal quality of Indonesia cigar tobacco leaves

A cigar leaf and an internal technology, applied in the field of improving the intrinsic quality of Indonesian cigar leaves, can solve the problems that chemical flavors and fragrances are not suitable for cigars, Indonesian tobacco leaves have a bitterness, and the compatibility is not strong, so as to increase oral comfort and promote The effect of degrading protein and increasing the softness of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

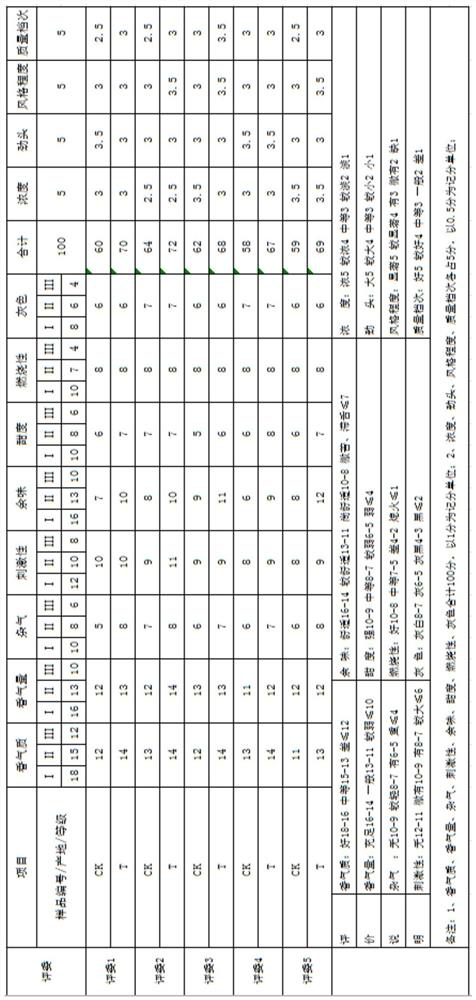

Embodiment 1

[0022] Put the procured Indonesian-made cigar tobacco leaves that have been fermented once at 45±3°C and 80±5% humidity for 24 hours to fully rehydrate and soften. Vanilla beans and cinnamon are dried in an oven below 150°C, ground, passed through a 60-mesh sieve, and mixed according to a mass ratio of 1:1 to obtain natural plant powder. The rehydrated tobacco leaves are unfolded, and the obtained natural plant powder is evenly sprayed on the leaves, and the added amount of the natural plant powder is 2% of the mass of the tobacco leaves. The resulting cigar leaves sprayed with natural plant powder were placed in an environment with a temperature of 50° C. and a humidity of 70% to ferment for 6 days.

Embodiment 2

[0024] The difference from Example 1 is that the natural plant powder raw materials are licorice, vanilla beans, cassia bark and hawthorn, and the mass ratio is 1:1:1:1.

Embodiment 3

[0026] The difference from Example 1 is that the natural plant powder raw materials are licorice, vanilla beans, cassia bark and hawthorn, with a mass ratio of 1:1:2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com